Temperature measurement board and temperature measurement system

A technology of temperature measuring lines and temperature measuring points, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of low temperature measurement efficiency of circuit boards, achieve high applicability, and improve the effect of temperature measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

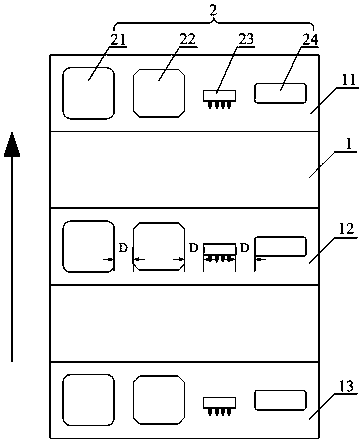

[0033] see figure 1 , is a structural schematic diagram of a temperature measuring plate provided by an embodiment of the present invention. like figure 1 As shown, the temperature measuring board includes a motherboard 1 .

[0034] Wherein, the motherboard 1 includes a plurality of mutually separated temperature measurement areas arranged along the direction of entering the furnace. In an exemplary embodiment, the shown motherboard 1 includes three temperature measurement areas, namely the first temperature measurement area 11, the second temperature measurement area 12 and the third temperature measurement area 13; the above three temperature measurement areas can be along the The direction of entering the furnace of the temperature measuring plate is set, and the direction of entering the furnace is as follows: figure 1 As shown, it can be understood as the direction in which the temperature measuring board enters the reflow oven; wherein, along the furnace entering dire...

Embodiment 2

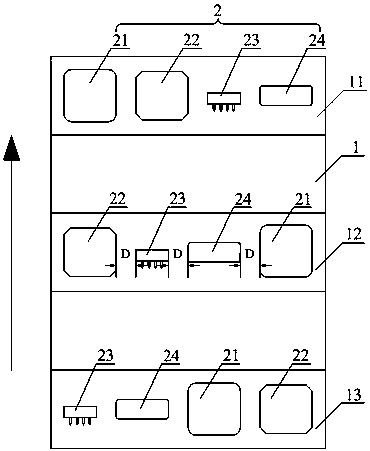

[0041] see figure 2 , is a schematic structural diagram of another temperature measuring board provided by an embodiment of the present invention. like figure 2 As shown, the temperature measuring board includes a motherboard 1; in the embodiment of the present invention, the motherboard 1 is provided with three temperature measuring areas separated from each other along the direction of entering the furnace, that is, the first temperature measuring area 11, the second Temperature measurement area 12 and the third temperature measurement area 13; In each temperature measurement area, a plurality of different types of temperature measurement elements 2 are provided, and the temperature measurement elements 2 include BGA elements 21, FQN elements 22, temperature sensitive There are 4 types of components 23 and connector components. The difference between the embodiment of the present invention and the first embodiment lies in that the temperature measuring elements 2 of the ...

Embodiment 3

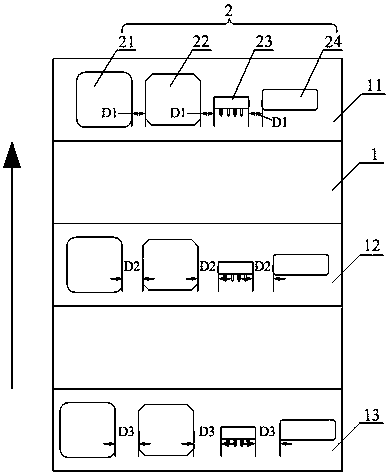

[0046] see image 3 , is a schematic structural diagram of another temperature measuring board provided by an embodiment of the present invention. like image 3 As shown, the temperature measuring board includes a motherboard 1; in the embodiment of the present invention, the motherboard 1 is provided with three temperature measuring areas separated from each other along the direction of entering the furnace, that is, the first temperature measuring area 11, the second Temperature measurement area 12 and the third temperature measurement area 13; In each temperature measurement area, a plurality of different types of temperature measurement elements 2 are provided, and the temperature measurement elements 2 include BGA elements 21, FQN elements 22, temperature sensitive There are four types of elements 23 and connector elements 24 in total. The difference between the embodiment of the present invention and the first embodiment lies in that, in each temperature measurement ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com