Split type insulation intermediate tank induction heater

A technology for induction heaters and tundishes, applied in metal processing equipment, casting molten material containers, casting equipment, etc., can solve the problems of low energy efficiency ratio of equipment, large temperature fluctuations, heat generation, etc., and achieve improved energy efficiency ratio and high-efficiency heating The effect of heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

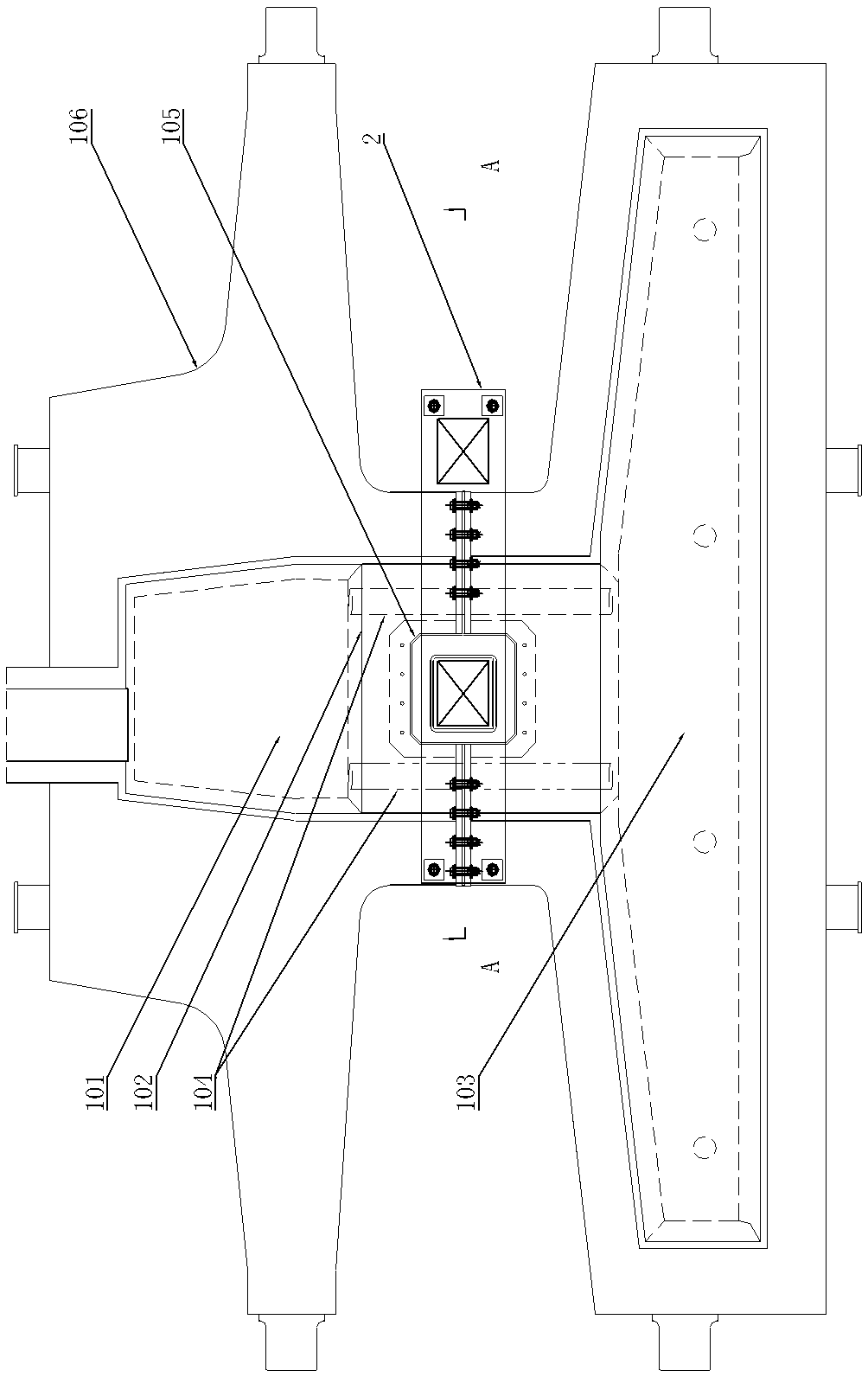

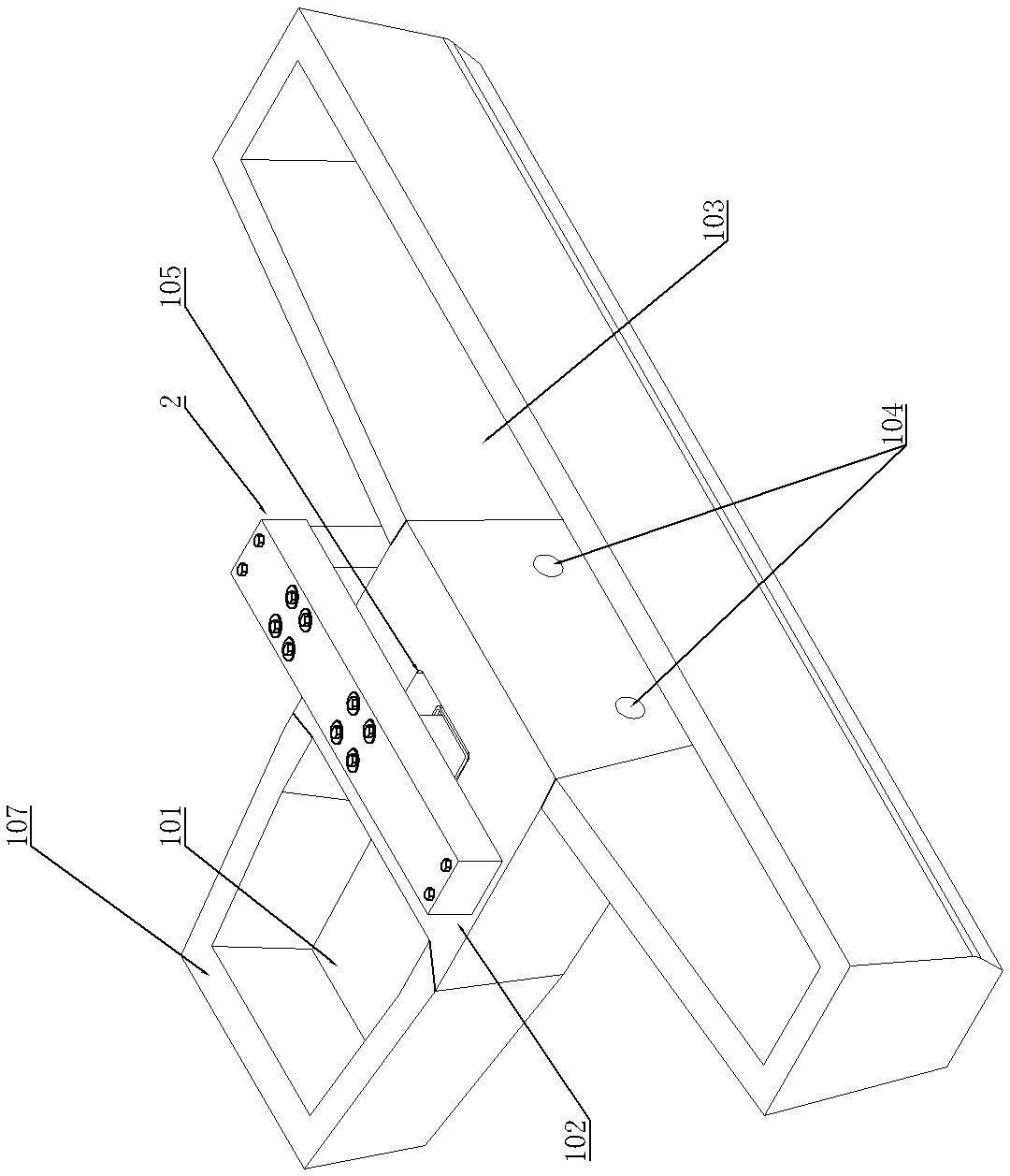

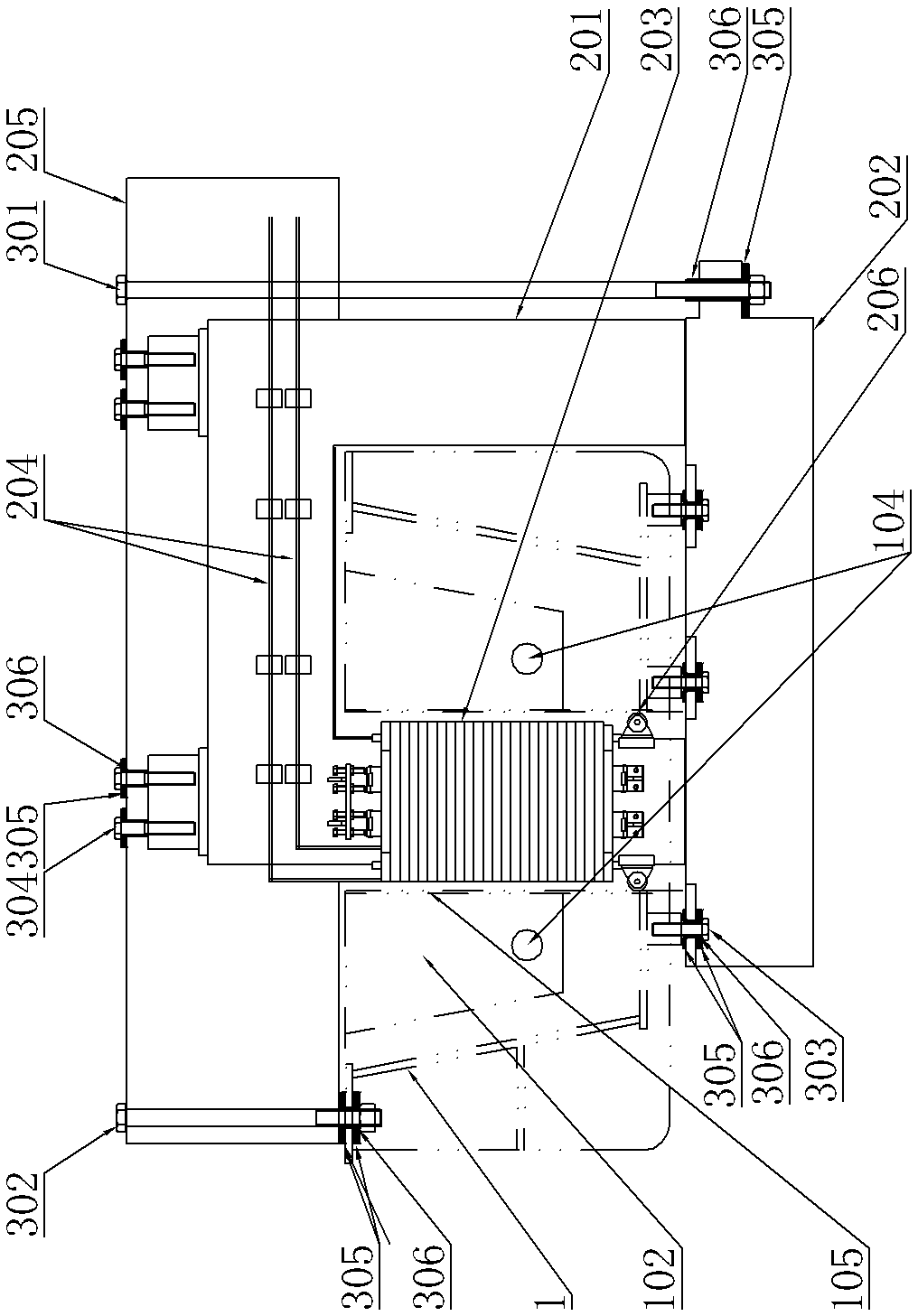

[0023] Such as Figure 1~Figure 7 As shown, the split-type insulated tundish induction heater consists of two parts: the split-type insulating tundish 1 and the split-type insulating induction heater 2. The split-type insulating tundish consists of a split steel shell 106 of the tundish and a tundish The chamber-divided refractory body 107 (with insulation properties) is composed of the tundish chamber-divided refractory body 107 installed on the tundish split steel shell 106, and the tundish chamber-divided refractory body 107 is composed of molten steel impact chamber 101, The heater protection refractory body 102 and the molten steel casting cavity 103 are formed. The heater protection refractory body 102 is provided with two heating passages 104 and a heater coil installation hole 105. The two heating passages 104 are connected to the molten steel impact chamber 101 and the The molten steel casting cavity 103, the split insulated induction heater 2 is composed of an upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com