Manufacturing method of integral flange

A manufacturing method and integral flange technology, applied in building elements, metal material coating process, etc., can solve the problems of wasting materials and equipment occupation, and achieve the effect of saving occupation, good coaxiality, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

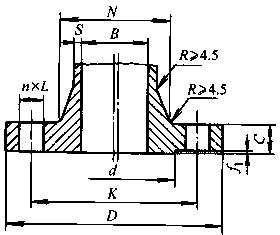

[0031] Example: such as figure 1 As shown, the size of the finished integral flange is 49mm in total length, and the outer diameter of the flange is 130mm, 70mm, and 55mm in order from large to small. The manufacturing method of the integral flange specifically comprises the following steps:

[0032] (1) Blanking and upsetting: the round steel is cut by a band sawing machine, and the round steel is cut into a bar-shaped blanking piece; the size of the blanking piece is φ130mm, and the length is 49mm; the blanking piece is cut by a mechanical automatic feeding device The parts are put into the high-frequency induction heating furnace, and the heating temperature is 1000~1100℃. The heated parts are pre-upset and formed by a 200T hydraulic press; first, the parts are placed on the lower head of the first press, and the press Under the application of pressure, the upper heading head presses down to divide the material and remove the oxide scale generated during heating, and upset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com