Rotary disc type battery pairing system

A technology of turntable type and electric core, which is applied in the direction of conveyor control device, cleaning device, conveyor, etc., can solve the problems of high dependence, unfavorable production technology promotion and application, and long production line, so as to reduce dependence and improve reliability. retroactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

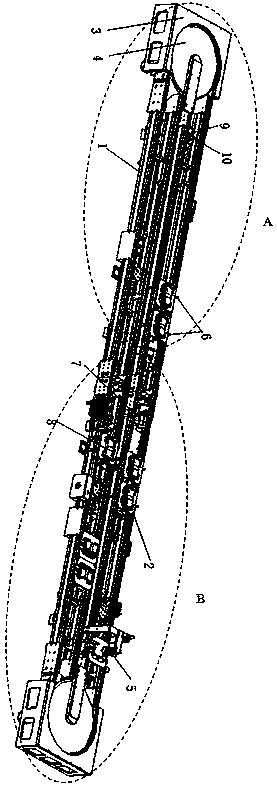

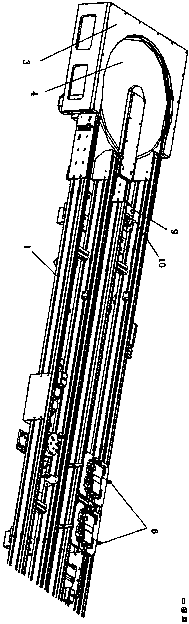

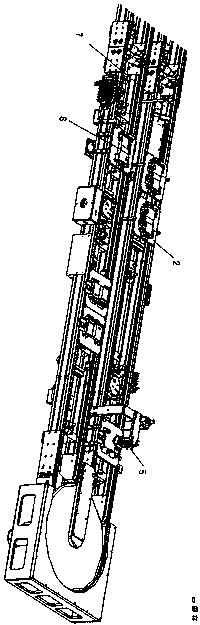

[0023] This embodiment provides a turntable battery pairing system, which includes two conveying frames 1 placed side by side, and pulleys are respectively provided at both ends of each of the conveying frames 1, and the pulleys of each of the conveying frames 1 are composed of Driven by their respective power mechanisms, the pulleys on each conveyor frame 1 are connected by a conveyor belt transmission. There are several jigs 2 on the conveyor belt. The jigs 2 are provided with some friction-reducing parts at the positions in contact with the conveyor belt. Bearings, wherein the number of fixtures 2 is determined by the capacity of the conveyor belt. In this embodiment, four bearings are provided on the jig 2, and each bearing has a T-shaped structure. The conveying racks 1 are connected to form a closed conveying loop through a rotating mechanism 3, the rotating mechanism 3 includes a turntable 4 and a turntable motor, and the turntable 4 is connected to the turntable motor ...

Embodiment 2

[0026] This embodiment is similar to Embodiment 1. Further, a buffer mechanism is provided between the sensor 6 and the color sensor 7. The buffer mechanism includes a proximity switch 9 and a blocking mechanism 10. The proximity switch 9 is used to detect the position of the jig 2 in real time. When the jig 2 enters the corresponding range, the blocking mechanism 10 precisely positions the jig 2 , and the buffer mechanism ensures the orderly operation of the spacing matching mechanism to a certain extent, avoiding excessive jigs 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com