Slide arm type slewing crane

A technology of cranes and sliding arms, which is applied in the field of sliding arm jib cranes, can solve problems such as inconvenience, inconvenience, and performance impact, and achieve the effect of not being damaged, not being damaged, and having good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

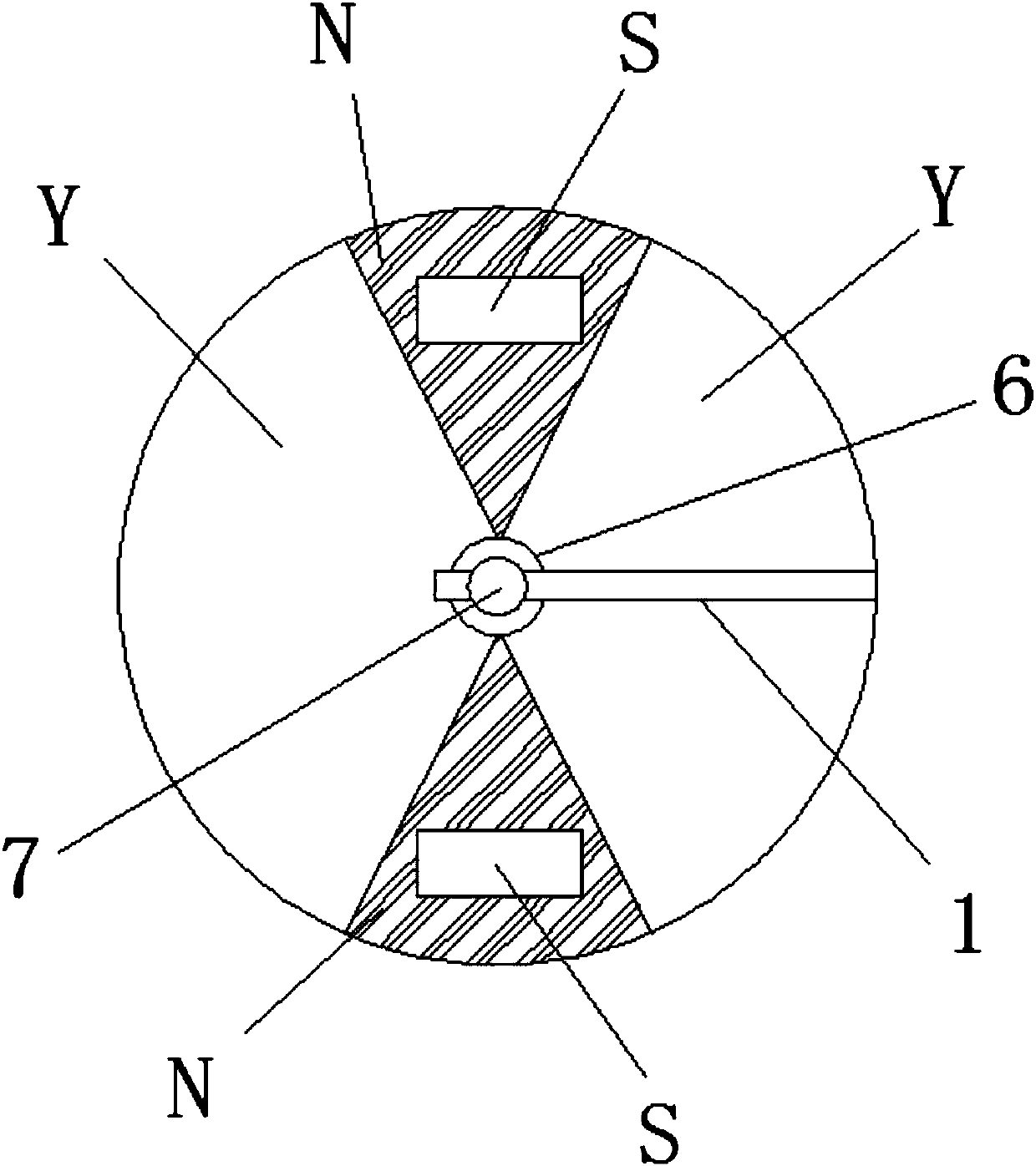

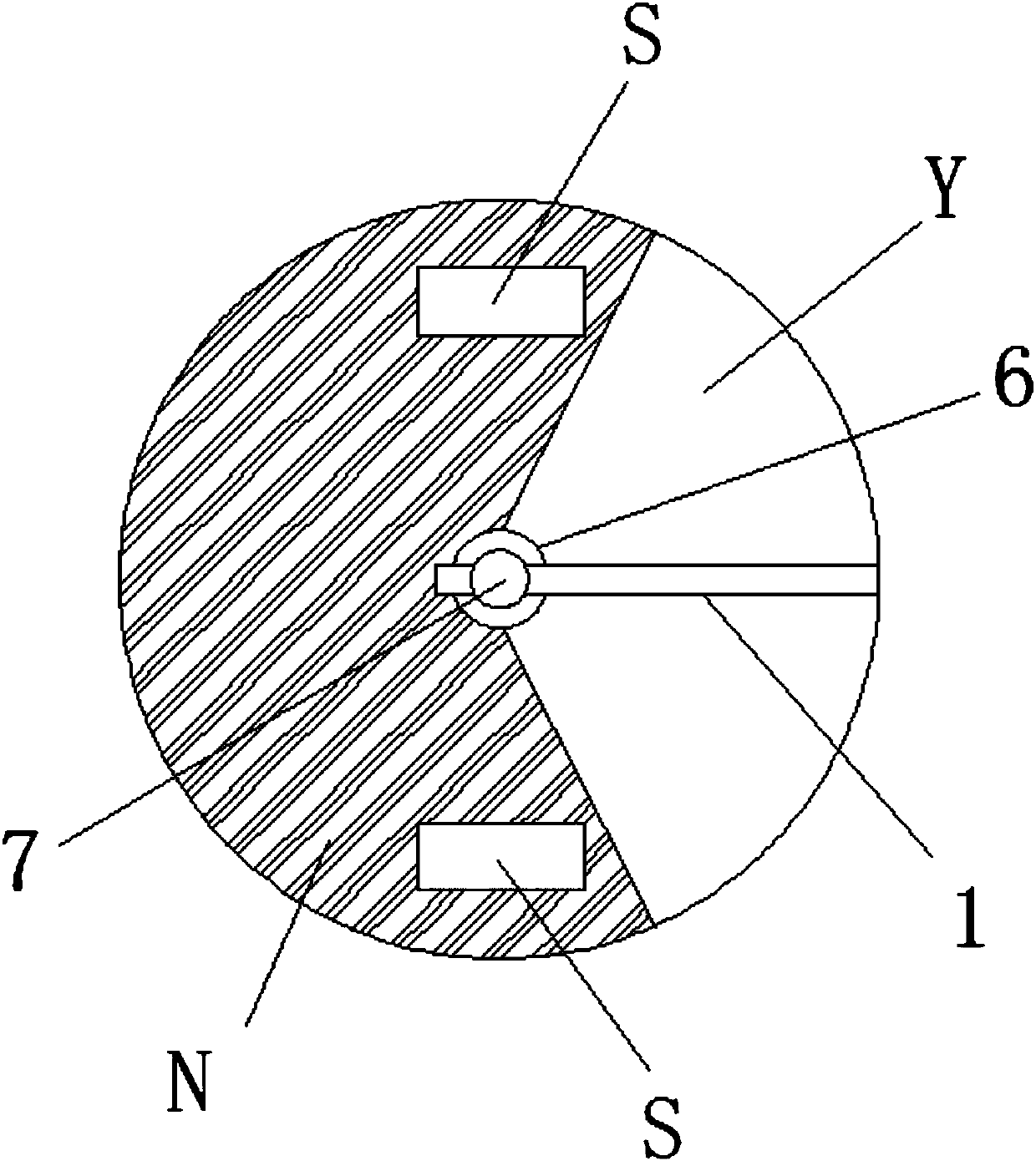

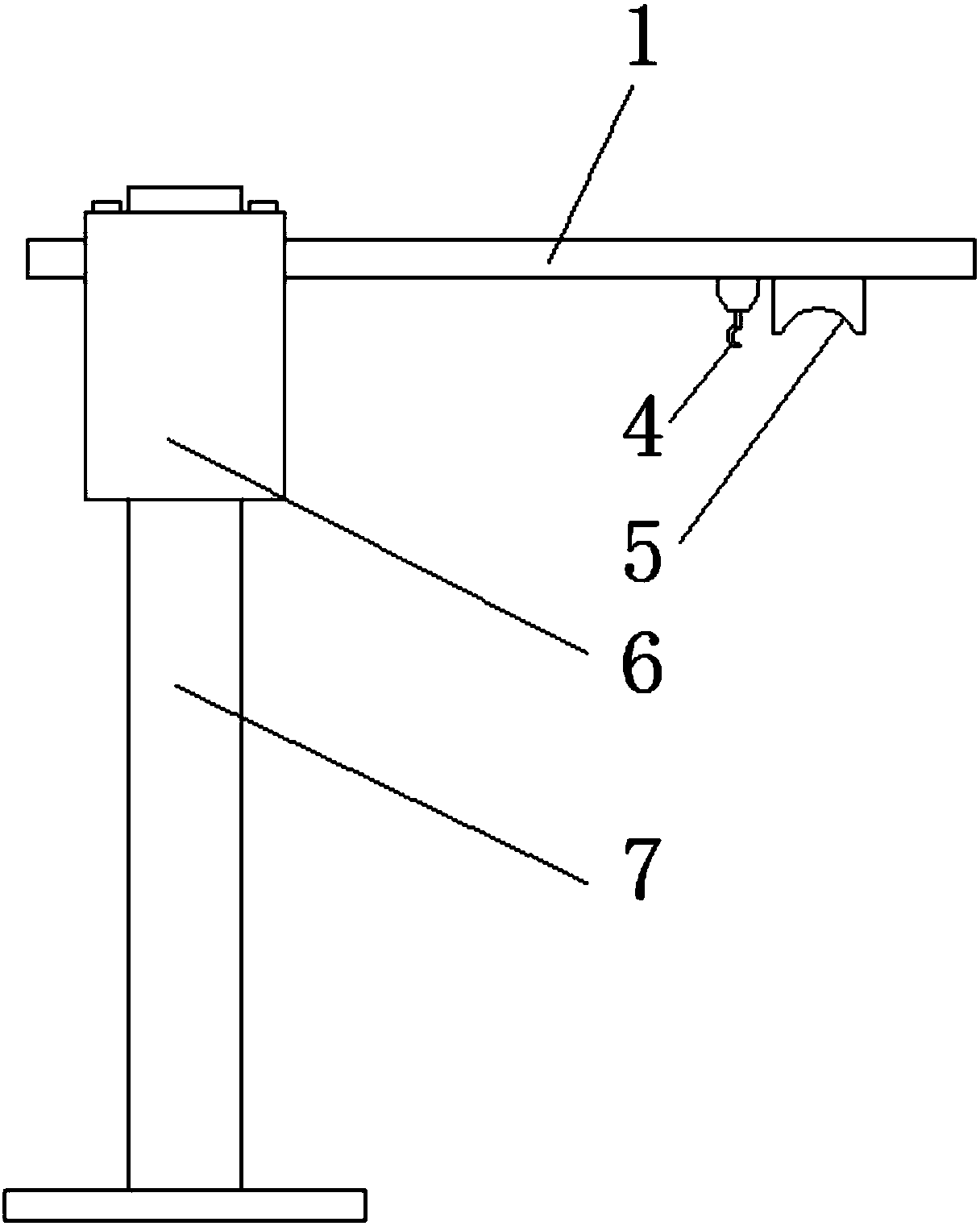

[0033] see Figure 1-7 , a sliding arm type jib crane, including a column body 7 with a rotary drive device, the column body 7 includes a fixed column and a rotating column, the fixed column is fixedly connected on the ground, and the rotating column is connected to the upper end of the fixed column in rotation, and the rotation A motor is installed between the column and the fixed column, and the rotation column is completed through the action of the motor and the rotary drive device. A sleeve 6 is sleeved on the outside of the rotation column, and a first opening is provided on the column body 7 . There is a second opening, the first opening matches the second opening, the swing arm 1 is interspersed in the first opening and the second opening, and the width of the first opening and the second opening is greater than the width between the swing arm 1 and the electric hoist 4 And, to ensure that the swing arm 1 equipped with the electric hoist 4 can pass through the first ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com