Anti-electromagnetic textile machine needle

A textile machine needle and anti-electromagnetic technology, which is applied to machine needles, textiles, papermaking, sewing machine components, etc., can solve the problems of ineffective anti-electromagnetic, unsatisfactory customers, and reduced work efficiency, so as to achieve good electromagnetic shielding performance and improve work efficiency. The effect of efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

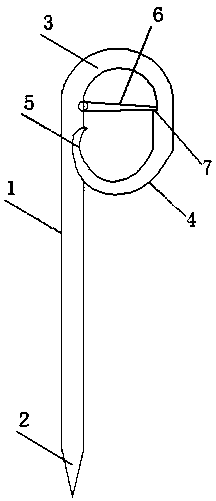

[0018] see figure 1 , the present invention relates to an anti-electromagnetic textile machine needle, comprising a needle body 1, a needle tip 2, a bend 3 and a hook 4, one end of the needle body 1 is connected to the needle tip 2, and the other end is connected to the bend 3, and the bend The hook part 4 is arranged at the other end of the bending part 3, and the hook tip 5 of the hook part 4 is bent toward the needle body part 1, and the needle body part 1 is provided with a groove, and the hook tip is embedded in the groove.

[0019] Wherein, a gear rod 6 is provided inside the bending part 3, and one end of the gear rod is connected with the needle body part 1 through a rotating pin, and the other end is arranged on the protruding step 7 provided on the bending part.

[0020] The surface of the textile machine needle is coated with an anti-electromagnetic coating, and the anti-electromagnetic coating contains polymethyl methacrylate resin as a matrix material and mesoporo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com