Honeycomb aluminum plate device with power generation function

A technology of honeycomb aluminum plate and function, which is applied in the field of construction or decoration, can solve the problems of single function and the inability of honeycomb aluminum plate to realize solar power generation, etc., and achieve the effects of good safety performance, increased strength and compressive performance, and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

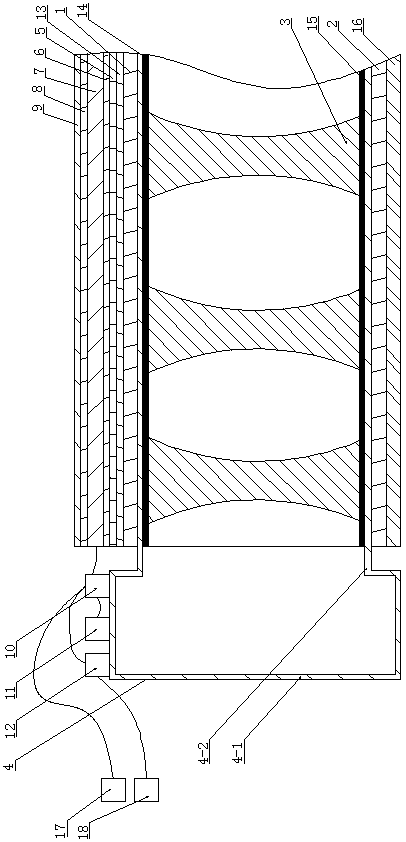

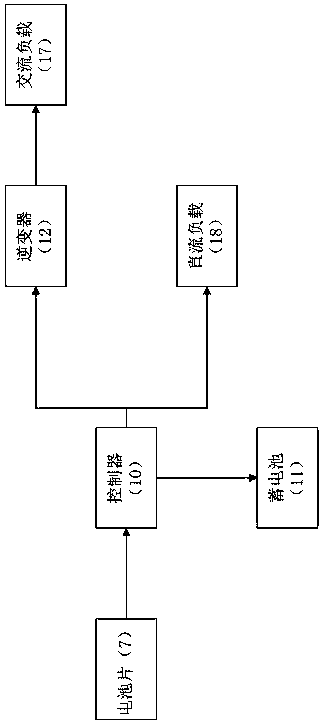

[0027] The honeycomb aluminum panel device with power generation function of the present invention includes a thin aluminum panel 1 and a thin aluminum base plate 2 arranged in parallel. The lower side of the thin aluminum base plate 2 is coated with a protective back coating 16, which effectively protects the thin aluminum base plate 2. Service life. An aluminum honeycomb core 3 is installed between the thin aluminum panel 1 and the thin aluminum bottom plate 2, and the aluminum honeycomb core 3 is surrounded by an aluminum support frame 4; the aluminum support frame 4 has a convex structure. The aluminum supporting frame 4 includes a supporting frame 4-2 and an outer frame 4-1 installed at one end of the supporting frame 4-2. The outer frame 4-1 and the supporting frame 4-2 are integrally formed. The supporting frame 4-2 is installed between the lower side of the thin aluminum panel 1 and the upper side of the thin aluminum bottom plate 2. The two sides of the supporting fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com