Automatic drainage system and method for centrifugal turbine compressor

A turbo compressor and automatic drainage technology, which is applied in the direction of machines/engines, mechanical equipment, radial flow pumps, etc., can solve the problem of secondary steam being easily atomized and condensed into water droplets, increasing the safety risk of manual operation, compressor components and Pipeline impact and other issues, to achieve the effect of flexible and adjustable drainage time and frequency, saving long-term maintenance costs, and avoiding the entry of external air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with each accompanying drawing.

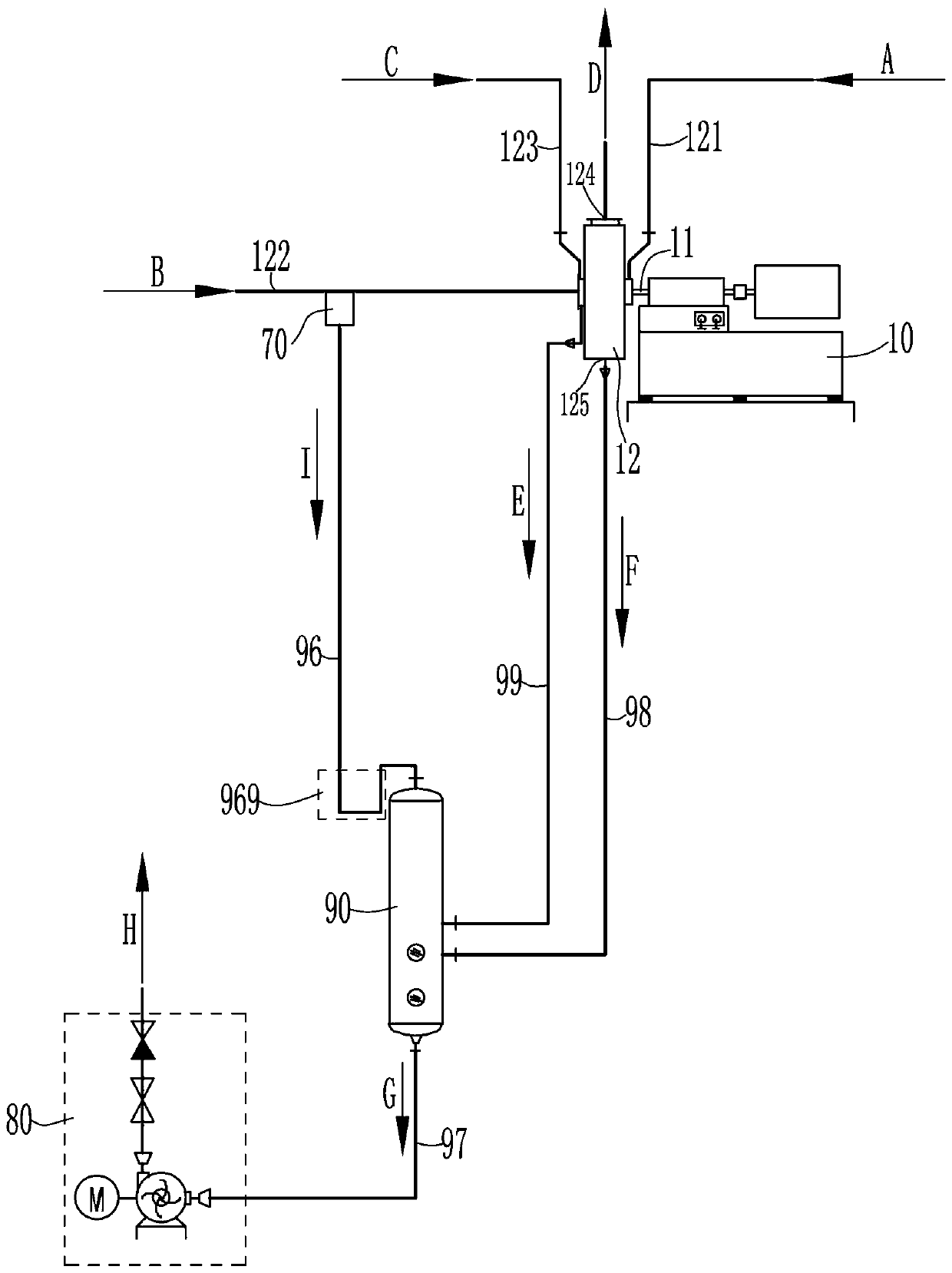

[0024] see figure 1 , an automatic drainage system for a centrifugal turbocompressor, comprising a centrifugal turbocompressor 10, a labyrinth seal ( Not shown, the specific structure of the labyrinth seal is the prior art, and will not be repeated here), the volute 12 is provided with a primary steam pipeline 121 for the primary steam to enter, and a secondary steam pipeline for the secondary steam to enter 122. The cooling water pipeline 123 for the cooling water to enter, the air outlet 124 for the secondary steam outlet, and the drain outlet 125 at the bottom for the accumulated water to be discharged; the automatic drainage system of the centrifugal turbocompressor also includes a drainage tank 90, a drainage pump 80 and the control circuit (not shown) for controlling the operation of the drainage pump 80; the condensate pipe 99 connects the drainage ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com