Reinforced concrete water pipe

A technology for reinforced concrete and concrete pipes, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., which can solve problems such as infiltration, sewage leakage, and impact on product service life, and achieve the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

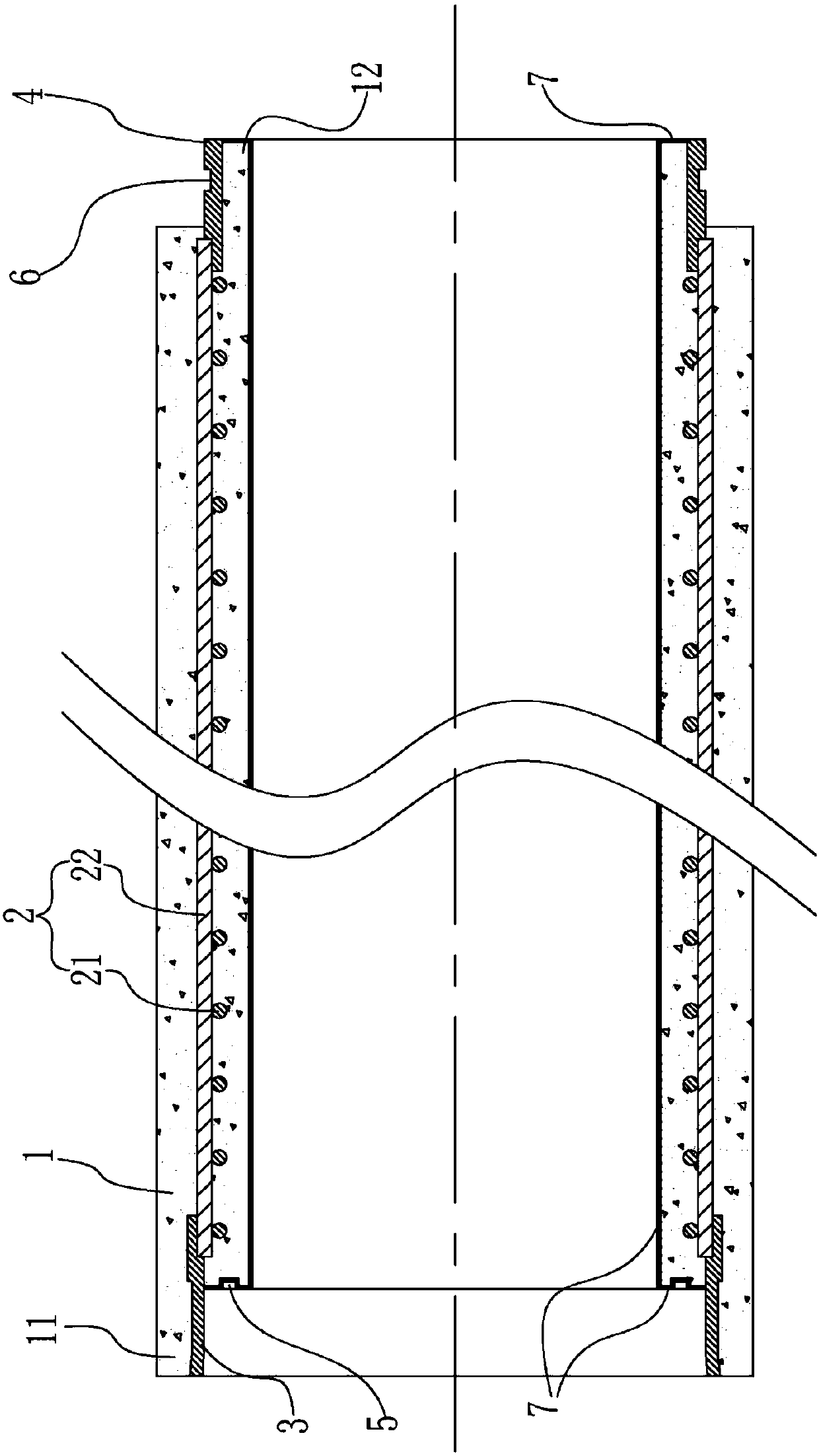

[0015] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] As shown in the figure, the present invention proposes a reinforced concrete water pipe, including a concrete pipe core 1 and a steel skeleton 2, wherein the concrete pipe core 1 is generally cylindrical, and the two ends of the concrete pipe core 1 are respectively integrally arranged There are a socket support ring 11 and a socket support ring 12, wherein the inner diameter of the socket support ring 11 is greater than the outer diameter of the socket support ring 12, so as to facilitate the installation and support of the steel socket 3 on the inner wall of the socket support ring 11 and support in the socket The outer wall of the ring 12 mounts and supports the steel socket 4;

[0017] The reinforcement skeleton 2 is generally cylindrical and formed by connecting annular reinforcement 21 and axial main reinforcement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com