Flue gas treatment method and system for reducing dioxin content in waste incineration

A flue gas treatment system and flue gas treatment technology, applied in combustion methods, incinerators, combustion types, etc., can solve the problems of up-to-standard emission, complex dioxin generation process, difficult dioxin concentration, etc., and reduce emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A flue gas treatment method for reducing dioxin content in waste incineration, using a flue gas treatment system for flue gas purification treatment, specifically comprising:

[0042] Steps to control the load of the boiler: Unload the garbage from the hopper into the garbage incinerator and drop it on the grate, and at the same time pass through the primary air and the secondary air, and the garbage will be incinerated for 1.5 hours under sufficient combustion gas. During the process, the boiler load is controlled to be 50t / h; it also includes controlling the temperature of the waste incinerator to be greater than 850°C, the time for flue gas to stay in the waste incinerator to be greater than 2s, and the ratio of primary air volume to secondary air volume to be 3:1 .

[0043] Among them, the waste incinerator is a Mitsubishi Martin reverse-push grate furnace with a single processing capacity of 500t / d, and is also equipped with a 15MW steam turbine generator set.

[...

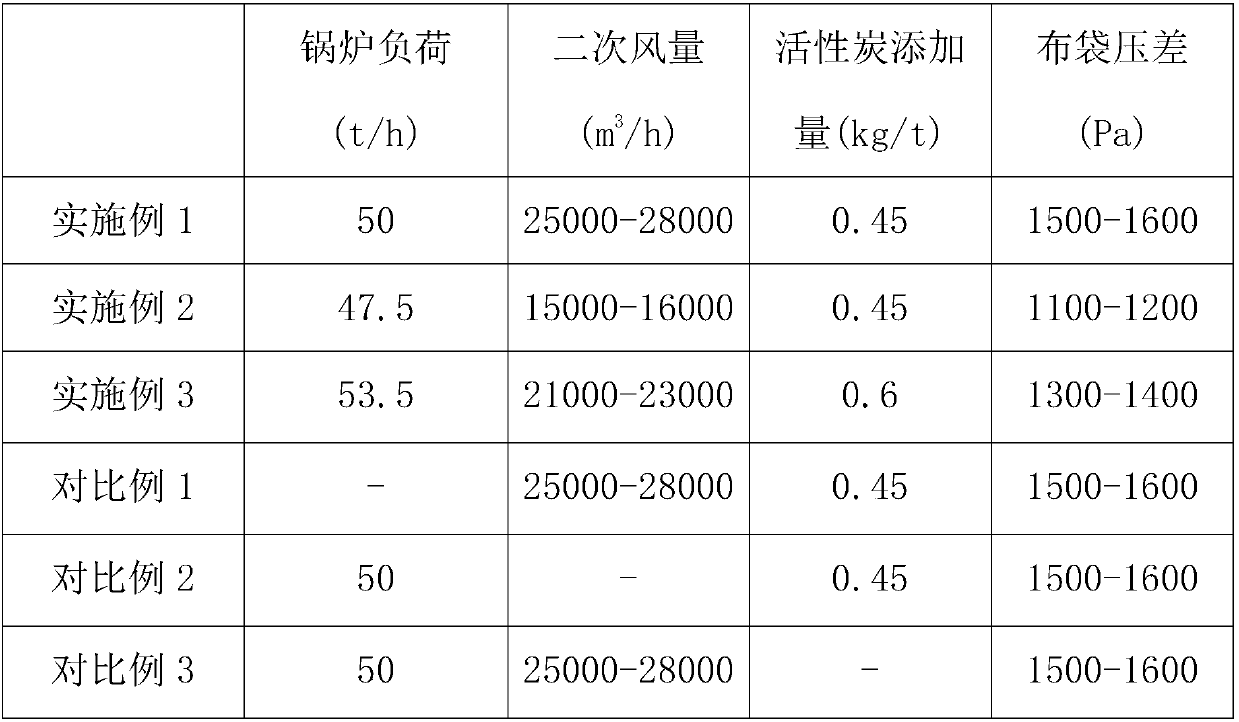

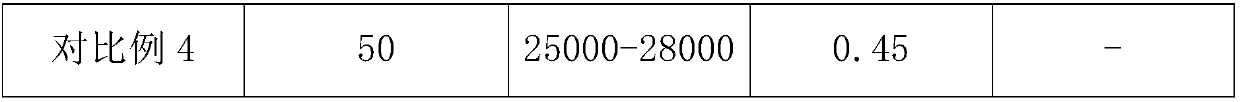

Embodiment 2-3 and comparative example 1-4

[0048] The operating steps of Examples 2-3 and Comparative Examples 1-4 refer to the processing method of the above-mentioned Example 1, wherein the design of the operating parameters refers to Table 1, and "-" indicates that the parameter is not controlled.

[0049] The operating parameters of each embodiment of table 1

[0050]

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com