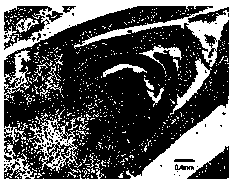

Paraffin slicing method for large explant leaf-buds and flower-buds of carnation

A paraffin section and explant technology, which is applied in the preparation, sampling, measuring device and other directions of samples for testing, can solve the problems of difficult xylene tissue, increased brittleness of materials, fragile tissue and other problems, and achieves good development and application value. Extend the wax soaking time and complete the sectioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Material collection and fixation:

[0039] Take carnation leaf buds of different development stages, the length of the buds is 0.5-3cm, and cut the buds in half from the center lengthwise, and then quickly place them in FAA fixative solution (formalin: glacial acetic acid: 70% ethanol = 1: 1:18), fixed for 24h, and stored in a refrigerator at 4°C;

[0040] (2) Cleaning and dyeing:

[0041] Wash the material obtained in step (1) with distilled water for 3 times, each time for 2 minutes; then place it in a 2mL centrifuge tube, stain with hematoxylin dye solution for 24 hours, wash with distilled water for 3 times, each time for 2 minutes, and then use a concentration of 70v / v% Washed twice with ethanol, 10min each time;

[0042] (3) Dehydration:

[0043] Dehydrate with ethanol with a concentration of 70v / v% for 12h, discard the ethanol, put the material into a 2mL centrifuge tube and centrifuge at 2000 rpm for 1min, replace with a new 2mL centrifuge tube, and dehyd...

Embodiment 2

[0057] (1) Material collection and fixation:

[0058] Take carnation flower buds of different development stages, the length of the buds is 0.5-3cm, and cut the buds in half from the center, and then quickly place them in FAA fixative solution (formalin: glacial acetic acid: 70% ethanol = 1: 1:18), fixed for 24h, and stored in a refrigerator at 4°C;

[0059] (2) Cleaning and dyeing:

[0060] Wash the material obtained in step (1) with distilled water for 3 times, each time for 5 minutes; then place it in a 2mL centrifuge tube, stain with hematoxylin dye solution for 24 hours, wash with distilled water for 3 times, each time for 5 minutes, and then use a concentration of 70v / v% Washed twice with ethanol, 10min each time;

[0061] (3) Dehydration:

[0062] Dehydrate with ethanol with a concentration of 70v / v% for 24h, discard the ethanol, put the material into a 2mL centrifuge tube and centrifuge at 3000 rpm for 2min, replace with a new 2mL centrifuge tube, and dehydrate with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com