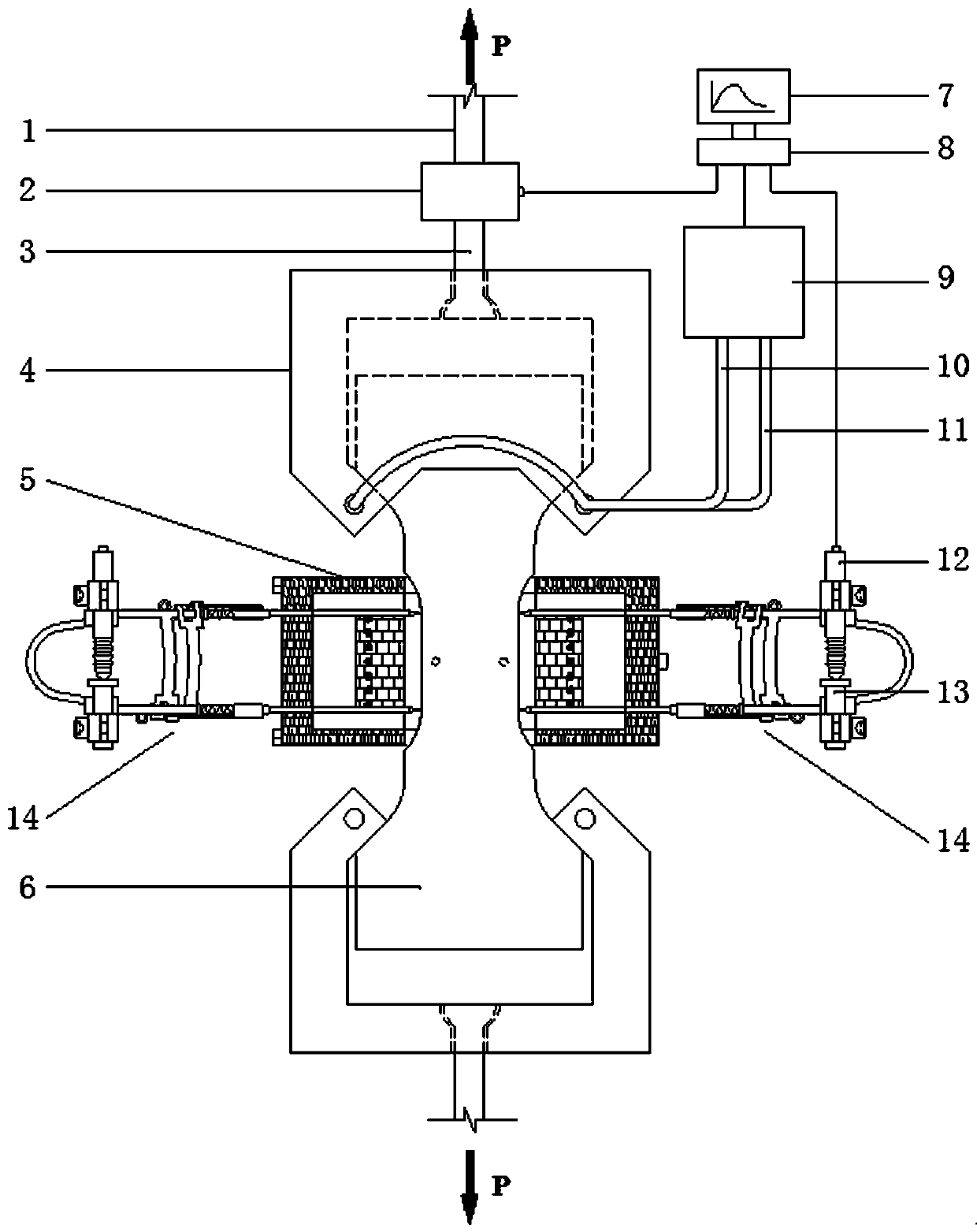

Concrete sample high-temperature tensile experiment device and fire simulation system thereof

A simulation system and test device technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the lack of fire simulation systems and other problems, achieve cost reduction, ingenious design, and reduce adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

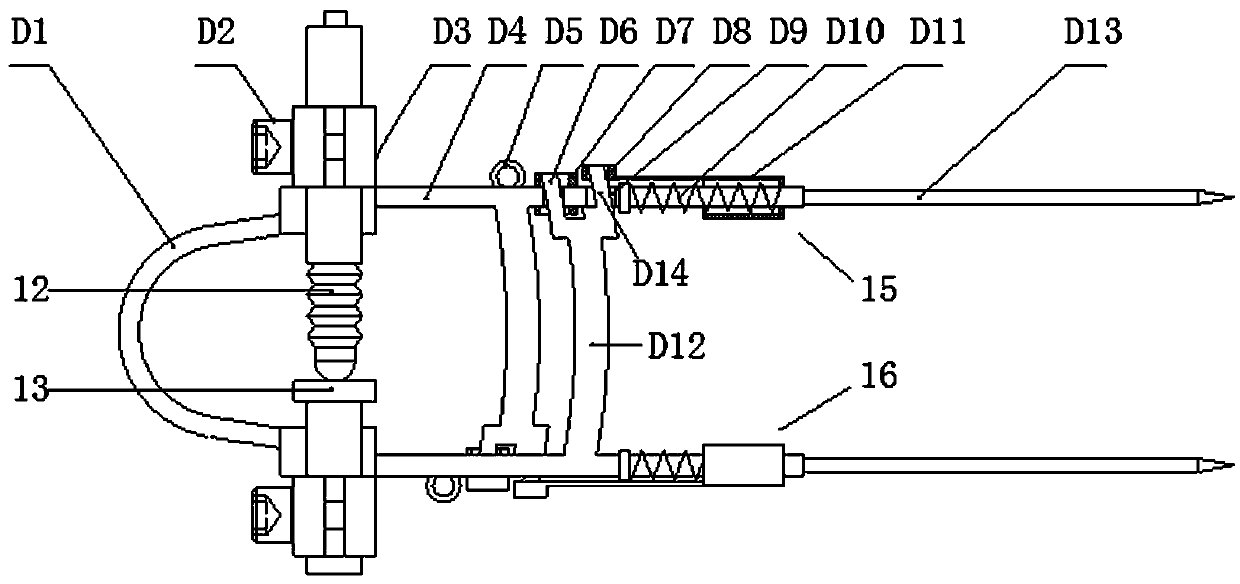

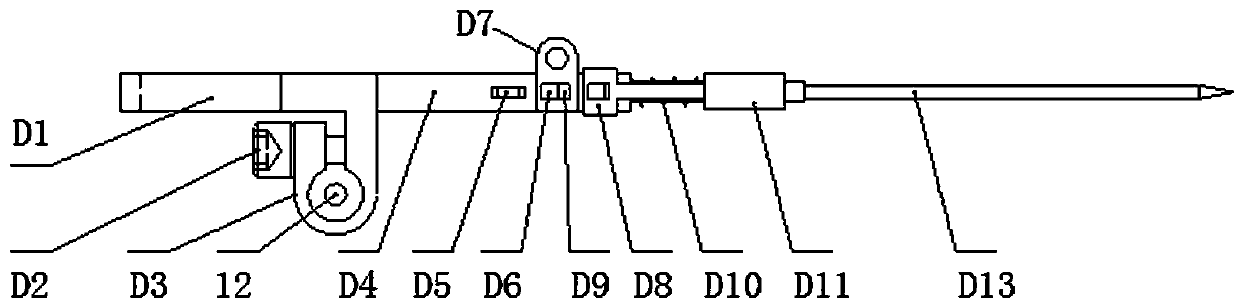

Embodiment Construction

[0033] First of all, it is emphasized that in the present invention, the test piece refers to the concrete test piece, and the test piece 6 adopts an "I"-shaped structure, such as Figure 5 , Figure 6 As shown, from the middle to both ends, it is divided into the fire receiving section A1, the force transmission section A2 and the loading section A3, and the fire receiving section A1 includes the test section A0. The fire section A1 is used to simulate the action of the fire; the test section A0 is also a predetermined fracture section for the test of strength and deformation performance; the force transmission section is used to provide enough space for the test operation; the load section A3 is used for tension imposed. In order to avoid the stress concentration at the variable section, the arc surface transition with radius R is adopted between the test section A0 and the force transmission section A2, and between the force transmission section A2 and the load section A3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com