Manufacturing process of human organ model

A technology of human organs and manufacturing process, which is applied in the medical field, can solve the problems of large obstacles to product marketing and use, difficulty in user identification and use, and insufficient differentiation, so as to facilitate promotion and use, ensure differentiation, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

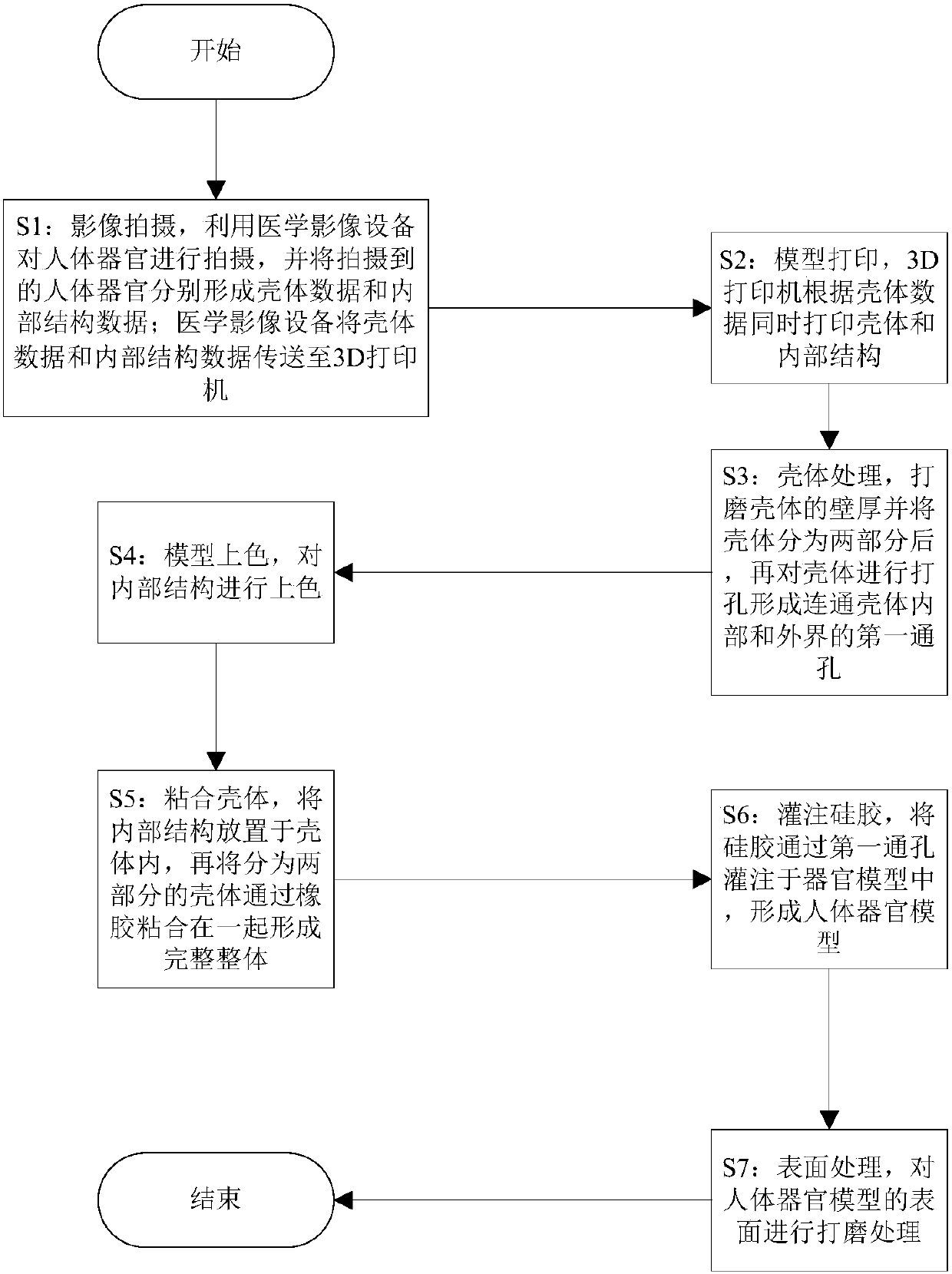

[0029] Such as figure 1 As shown, the present invention is a manufacturing process of a human organ model. The human organ model includes a shell and an internal structure located inside the shell, including: a 3D printer, a medical imaging device;

[0030] The manufacturing process of the human organ model includes the following steps:

[0031] S1: Image shooting, use medical imaging equipment to shoot human organs, and form the captured human organs into shell data and internal structure data; the medical imaging equipment transmits shell data and internal structure data to the 3D printer;

[0032] S2: Model printing, the 3D printer simultaneously print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com