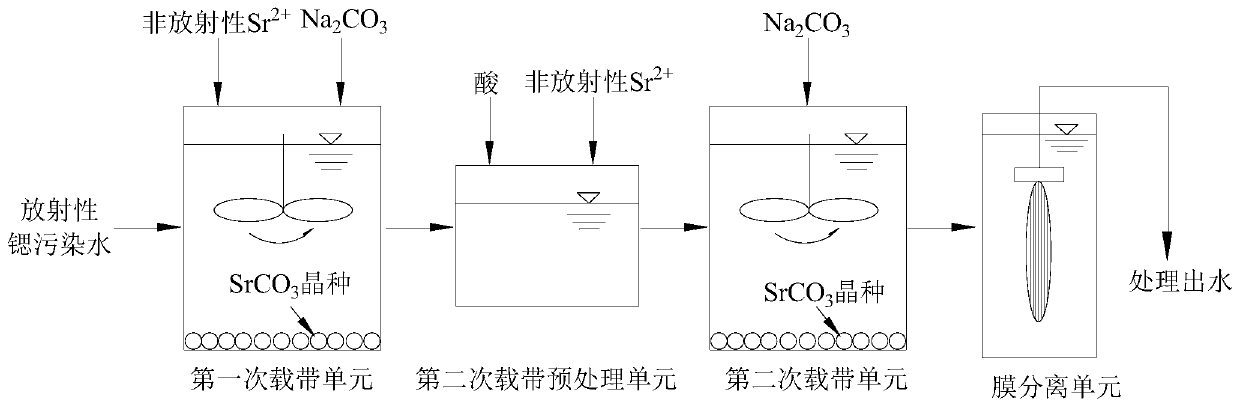

Method for treating radioactive strontium polluted water by secondary carrier co-precipitation-membrane separation

A technology of radioactive strontium and co-precipitation method is applied in the treatment of radioactive strontium polluted water, secondary carrier co-precipitation-membrane separation treatment of radioactive strontium polluted water, and can solve the problem of low utilization rate of precipitating agent, high pH value, and strontium effect. It can reduce the pH value, improve the decontamination factor, and improve the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 0.15g / L SrCO with an average particle size of 100μm to the first and second loading units in advance 3 Seed. Prepare the mass concentration with strontium chloride to be 8×10 -4 mg / L raw water containing non-radioactive strontium to simulate radioactive strontium contaminated water, enter the first carrier unit, add 4mg / L strontium chloride, and add 0.5g / L Na 2 CO 3 The precipitating agent was mechanically stirred at 150rpm for 15 minutes, and then settled for 15 minutes. The supernatant of the first carrier enters the second carrier pretreatment unit, and adds dilute hydrochloric acid to adjust the pH value to 8.3, then adds 36mg / L strontium chloride, mixes well and then enters the second carrier unit. Add 0.5g / L Na to the second carrier unit 2 CO 3 The precipitating agent was mechanically stirred at 150rpm for 15 minutes and statically settled for 8 minutes. The supernatant liquid entered the membrane separation unit and was filtered by the membrane module be...

Embodiment 2

[0025] Add 0.150g / L SrCO with an average particle size of 100μm to the first and second loading units in advance 3 Seed. Prepare the mass concentration with strontium chloride to be 8×10 -4 mg / L strontium-containing raw water to simulate radioactive strontium-contaminated water, enter the first carrier unit, add 12mg / L strontium chloride, and add 0.3g / L Na 2 CO 3The precipitating agent was mechanically stirred at 150rpm for 15 minutes, and then settled for 15 minutes. The supernatant of the first carrier enters the second carrier pretreatment unit, and adds dilute hydrochloric acid to adjust the pH value to 8.3, then adds 28 mg / L strontium chloride, mixes well and enters the second carrier unit. Add 0.7g / L Na to the second carrier unit 2 CO 3 The precipitating agent was mechanically stirred at 150rpm for 15 minutes and statically settled for 8 minutes. The supernatant liquid entered the membrane separation unit and was filtered by the membrane module before effluent. It ...

Embodiment 3

[0027] Add 0.085g / L SrCO with an average particle size of 50μm to the first and second loading units in advance 3 Seed. Prepare the mass concentration with strontium chloride to be 8×10 -4 mg / L strontium-containing raw water to simulate radioactive strontium-contaminated water, enter the first carrier unit, add 20mg / L strontium chloride, and add 0.9g / L Na 2 CO 3 The precipitating agent was mechanically stirred at 150rpm for 15 minutes, and then settled for 15 minutes. The supernatant of the first carrier enters the second carrier pretreatment unit, and adds dilute hydrochloric acid to adjust the pH value to 8.3, then adds 20mg / L strontium chloride, mixes well and then enters the second carrier unit. Add 0.1g / LNa to the second carrier unit 2 CO 3 The precipitating agent was mechanically stirred at 150rpm for 15 minutes and statically settled for 8 minutes. The supernatant liquid entered the membrane separation unit and was filtered by the membrane module before effluent. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com