Elastic barb medical bone screw

A bone screw and elastic technology, applied in the field of elastic barb medical bone screws, can solve the problems of complex load failure, insufficient screw tooth rigidity, internal thread damage, etc., to improve installation stability, improve installation accuracy, and not easy to misplace Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

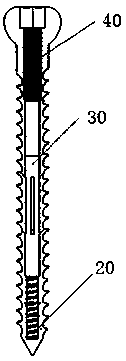

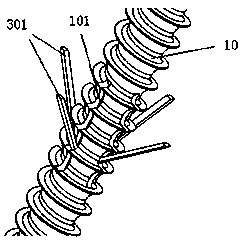

[0041] Such as figure 1 and figure 2 As shown, the present embodiment provides an elastic barb medical bone screw, including an outer nail 10 and an elastic barb member 30, and also includes an elastic reset member and an inner nail 40. The outer nail 10 is provided with an inner cavity, and the elastic reset member is located on At the bottom of the inner cavity of the outer nail 10, the elastic barb part 30 includes a mounting post 301 and a shrapnel 302. The elastic barb part 30 is arranged in the inner cavity of the outer nail 10. The upper end of the elastic reset part contacts the lower end of the mounting post 301, and the lower end of the inner nail 40 In contact with the upper end of the mounting post 301, the mounting post 301 is provided with a shrapnel receiving groove 303, one end of the shrapnel 302 is connected to the shrapnel receiving groove 303, the other end of the shrapnel 302 is ejected relative to the mounting post 301, and the ejection opening of the sh...

Embodiment 2

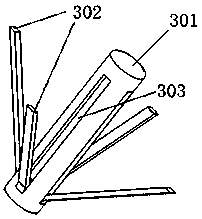

[0050] Such as image 3 As shown, this embodiment provides an elastic barb medical bone screw. This embodiment is similar to Embodiment 1, except that the elastic barb component 30 in this embodiment includes a mounting column 301 and four strip-shaped elastic pieces 302. The shrapnel 302 are symmetrically distributed around the axis of the mounting column 301. The four shrapnels 302 are connected to the shrapnel receiving groove 303 at the same radial section of the mounting post 301. The adjacent shrapnel 302 are in the axial direction of the mounting post 301. projections are perpendicular to each other.

[0051] The shrapnel are symmetrically distributed in the center of the mounting column 301 and fixed in the bone tissue. The force in the radial direction of the bone screw is balanced, and it is not easy to be misplaced, which improves the installation accuracy of the bone screw and reduces the difficulty of installation.

[0052] Four elongated elastic pieces 302 are a...

Embodiment 3

[0055] Such as image 3 As shown, this embodiment provides a medical bone screw with elastic barbs. This embodiment is similar to Embodiment 2, except that the included angle between the axis of the ejection hole 101 and the axis of the outer nail 10 in this embodiment is 45°.

[0056] The contact area between the elastic piece 302 and the bone tissue is consistent, and the force applied to the elastic piece 302 is consistent. The pop-up angle of the elastic piece 302 is 45°, and the sum of the radial and lateral force components of the mounting column 301 generated by the elastic piece 302 is the largest. At this time, the anti-rotation and pull-out resistance The overall effect of the load capacity is the best.

[0057] Preferably, the surfaces of the outer nail 10 and the shrapnel 302 are plated with titanium or titanium alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com