Modular fiber reinforced plastic poles

A technology of reinforced plastics and utility poles, applied in the field of utility poles, can solve the problems of limited use and high cost, and achieve the effect of low production cost and low life cycle cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

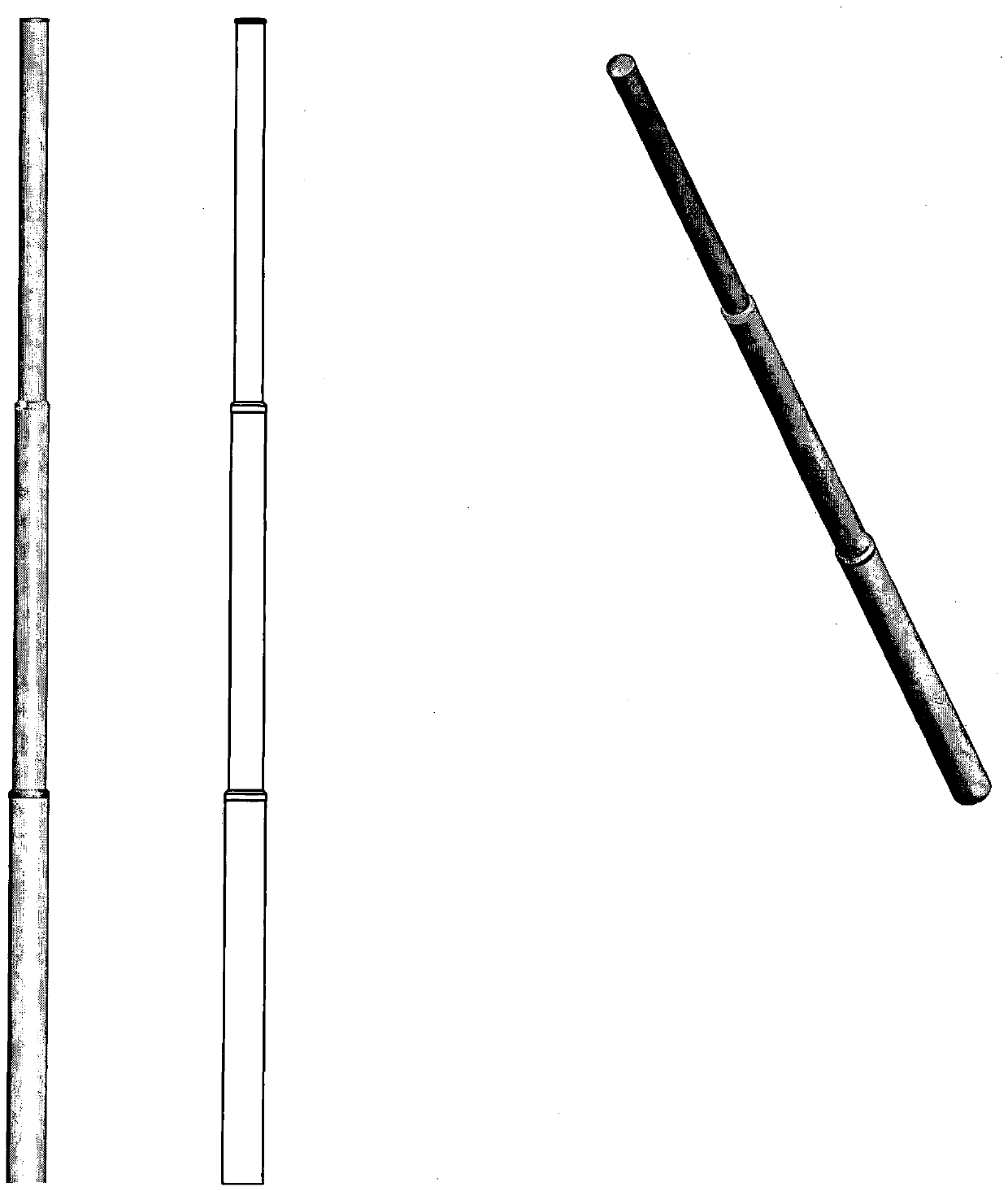

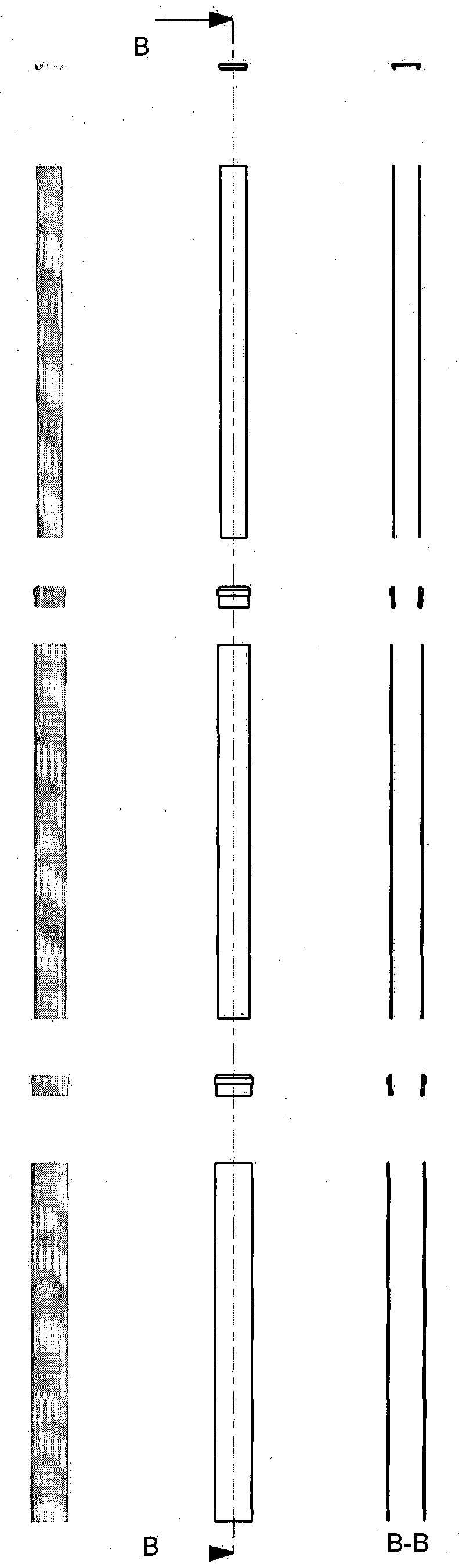

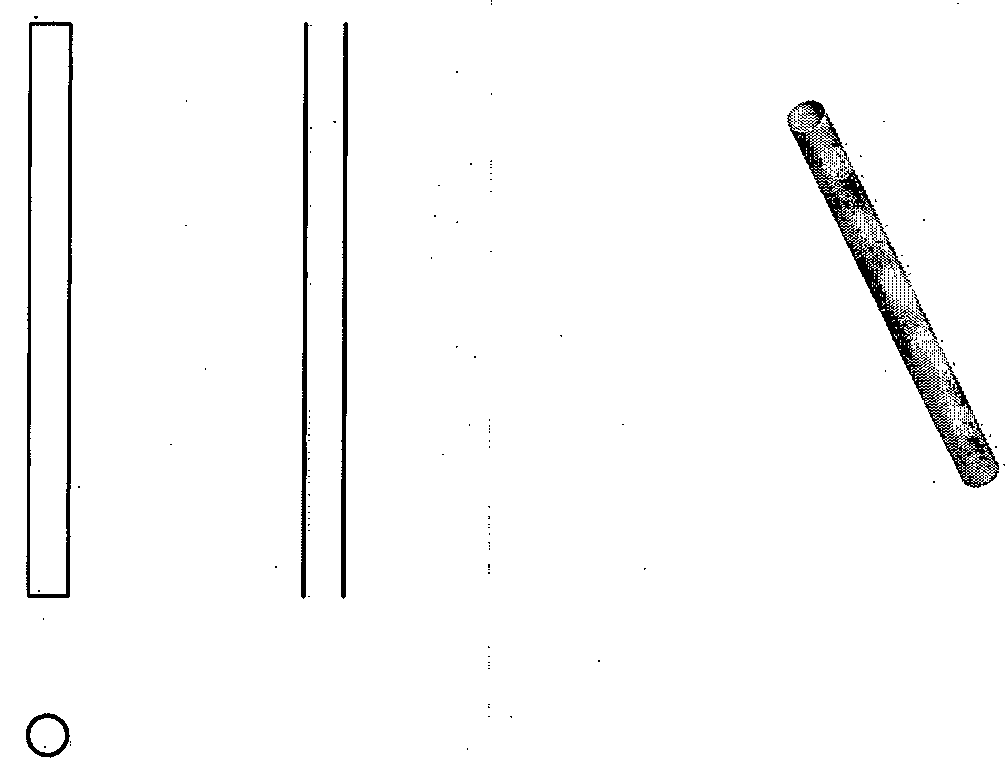

[0090] Figure 28 An example of a utility pole of the invention ready for industrial production is shown in full size.

[0091] Determination of the individual dimensions of the parts forming the utility pole of this embodiment was carried out by, using a finite element software package, considering first the mechanical stresses and strains that the utility pole must resist and secondly the strength of the reinforcing polymer from which the parts are made. Resistance and the direction of these resistances (compression-formed isotropic materials for joints and caps and pultruded anisotropic materials for cylindrical parts).

[0092] The utility pole of this embodiment is 7m long and complies with the requirements regarding specifications for correspondingly sized utility poles suitable for installation in the network. It also meets the requirements of relevant international standards (EN 50341, EN 50423).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com