Efficient precision hill-drop drill

A hole sowing machine, precision technology, applied in the direction of hole sowing seeder, planter parts, sowing, etc., can solve the problems of low efficiency and high labor intensity of manual sowing, and achieve the effect of simple structure, stable operation and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

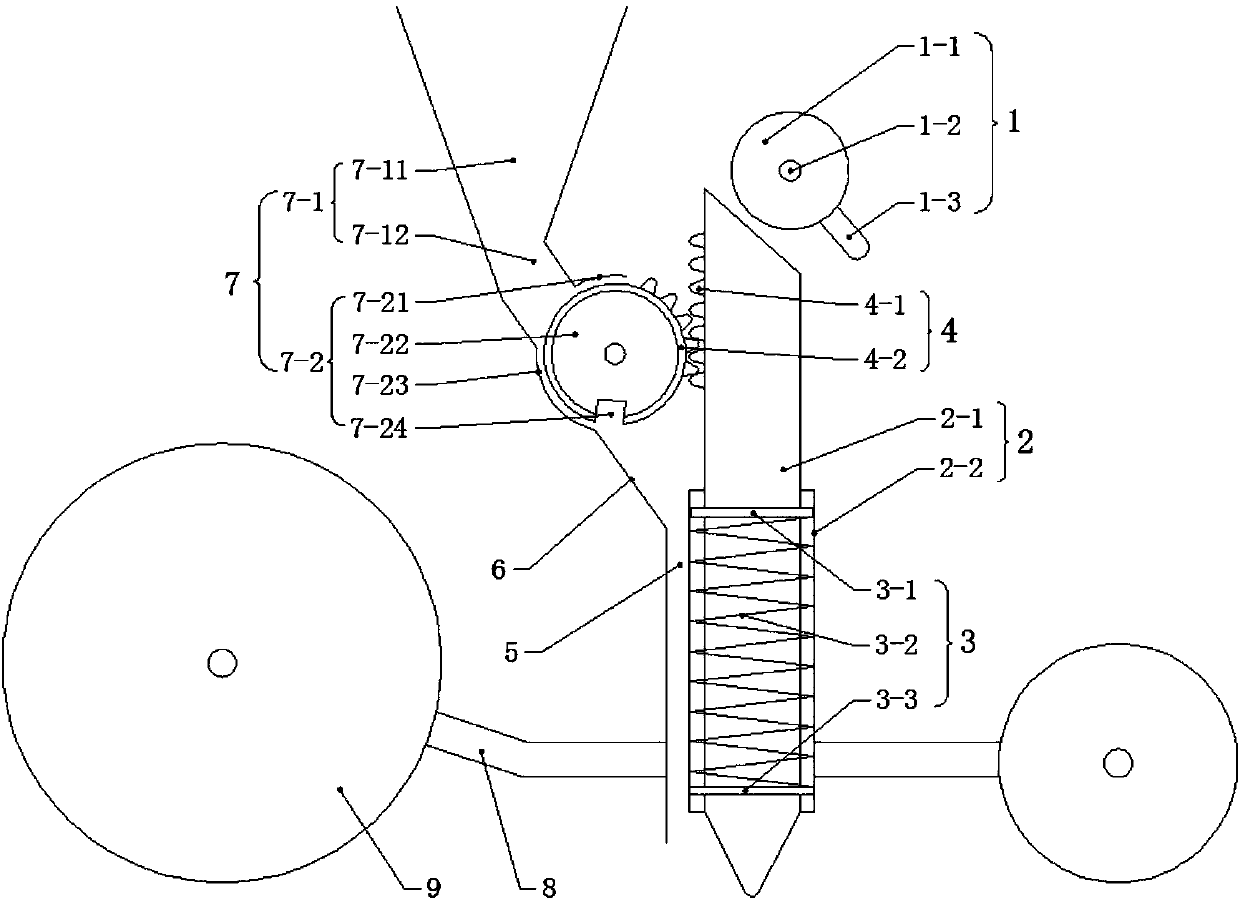

[0024] A high-efficiency precision hole seeder, comprising a frame 8, a wheel 9 and a motor are installed on the frame 8, and a sowing device is also arranged on the frame 8, and it is characterized in that: the described sowing device includes a driving mechanism 1, a hole opening The mechanism 2 and the seeding mechanism 7, the opening mechanism 2 is arranged under the driving mechanism 1, the seeding mechanism 7 is arranged on the left side of the hole opening mechanism 2, the driving mechanism 1 is connected with the engine, and the hole opening mechanism 2 includes a sleeve 2-2 With the hole opening rod 2-1 arranged in the sleeve 2-2, the top of the hole opening rod 2-1 contacts and cooperates with the driving mechanism 1, and the outer wall of the hole opening rod 2-1 is also sleeved in the sleeve 2-2. The rebound mechanism 3, the left side of the hole opening mechanism 2 is provided with a transmission mechanism 4 to connect and cooperate with the seed discharge mechanis...

Embodiment 2

[0028] This embodiment improves on the basis of Embodiment 1:

[0029] The top of hole opening bar 2-1 is inclined-plane shape, and drive mechanism 1 comprises the drive shaft 1-2 that is sleeved with drive wheel 1-1, and drive wheel 1-1 peripheral surface is provided with detachable drive block 1-3 and opening. The top of hole rod 2-1 contacts and cooperates, and the driving shaft 1-2 is provided with a sprocket to connect and cooperate with the engine.

[0030] Working principle: The engine drives the drive shaft 1-2 and the drive wheel 1-1 to rotate under the transmission of the sprocket and chain, so that the drive block 1-3 on the drive wheel 1-1 rotates, and the drive block 1-3 rotates to the drive wheel 1-1 is in contact with the slope at the top of the hole opening rod 2-1. With the rotation of the driving wheel 1-1, the driving block 1-3 drives the hole opening rod 2-1 by squeezing the top slope of the hole opening rod 2-1. 2-1 downward movement.

[0031] The advant...

Embodiment 3

[0033] This embodiment is improved on the basis of the above embodiments:

[0034] The transmission mechanism 4 includes an outer gear ring 4-2 and a rack 4-1 that cooperate with each other, the outer gear ring 4-2 is set on the circumference of the seed divider 7-22, and the rack 4-1 is set on the opening rod 2-1 On the left side outer wall, the position corresponding to the seed storage tank 7-24 on the circumference of the external ring gear 4-2 has an opening, and the upper part of the circumference of the external gear ring 4-2 has teeth.

[0035]The advantages of the above improvements are: by setting the external gear and the rack respectively on the seed divider and the hole opening rod, the rack drives the external gear to reciprocate by the up and down movement of the hole opening rod, thereby driving the seed divider to perform reciprocating separation. Seeding and sowing work, and this process can be repeated continuously, realizing the continuous and automatic sow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com