Picking and smashing mechanism for self-propelled reed baling press

A crushing mechanism and self-propelled technology, which is applied in packaging, agricultural machinery and implements, applications, etc., can solve the problems of poor picking and crushing effects of balers, achieve good picking and crushing effects, and improve stability and reliability , Improve the effect of picking up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in conjunction with the description of the drawings and specific embodiments.

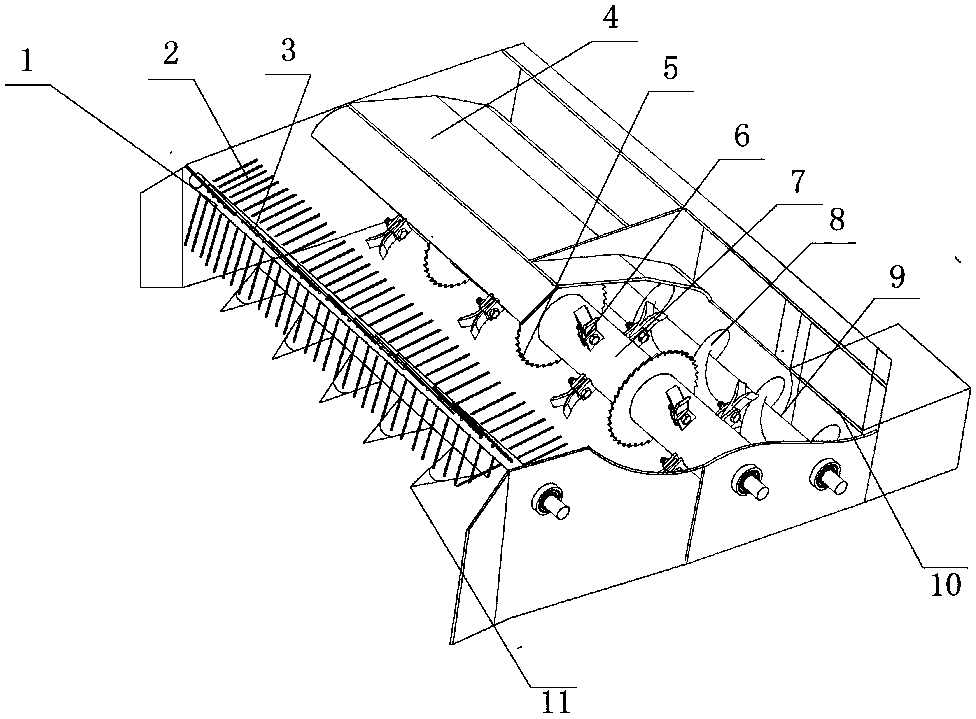

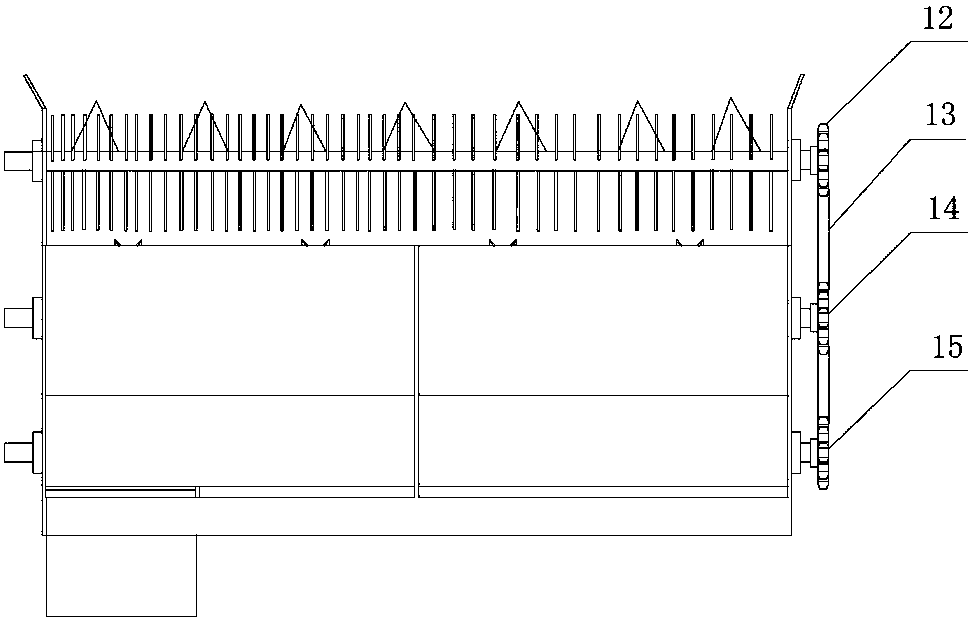

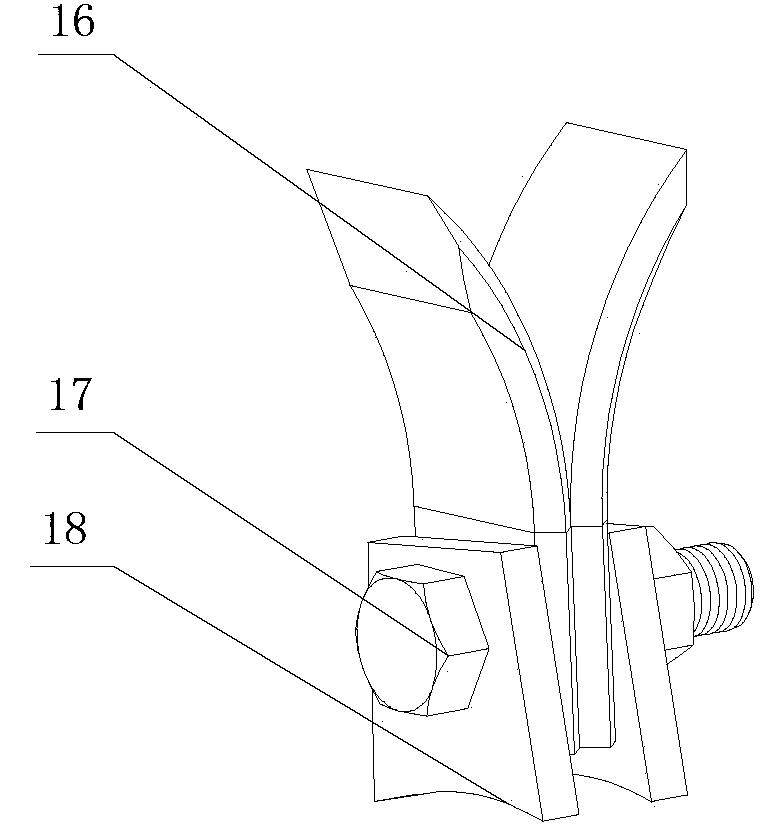

[0023] Such as figure 1 with figure 2 The picking and crushing mechanism of a self-propelled reed baler includes a chassis 4, a picking device, a crushing device and a conveying device, the picking device is installed in front of the chassis 4, and the crushing device, conveying device and discharge port are installed in the chassis 4 The rear; the pick-up device is located at the feed inlet 11 of the cabinet 4, and the pick-up device is made up of a pick-up device 1 and a grass-grass needle 2, and the grass-grass needle 2 is installed on the pick-up device 1; Knife 5 and swinging knife 6 are composed of saw blade cutter 5 and swinging knife 6 installed on swinging knife shaft 7; the conveying device is composed of auger shaft 9 and auger blade 8, auger blade 8 is installed on auger shaft 9 Above, the conveying device is located behind the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com