A photocatalyst loading method

A photocatalyst and catalyst technology, applied in the field of materials, can solve the problems of low quantum conversion efficiency, narrow photoresponse range, and low solar energy utilization rate, and achieve the effects of not easy to wipe off, high catalytic activity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

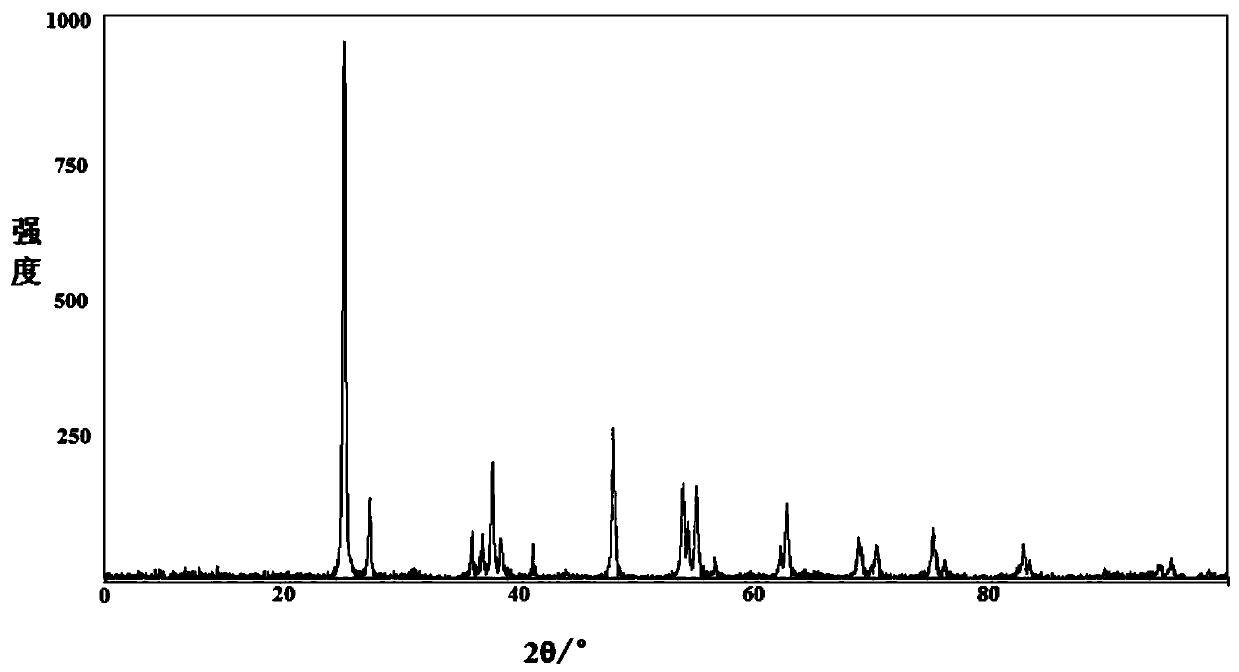

Image

Examples

Embodiment 1

[0037] A photocatalyst loading method, comprising the steps of carrier pretreatment, catalyst loading, heat treatment, and post-treatment, specifically:

[0038] A carrier pretreatment: the glass ball (tube) carrier is pretreated, washed and dried at 200°C for later use; the carrier pretreatment method is to mechanically grind the carrier, and the pressure of the grinding disc is 55kPa; after grinding, it is polished, first using HF Soak for 15s, then add H at a concentration of 3mol / L 2 SO 4 deal with.

[0039] B catalyst loading: modified TiO 2 After the catalyst is evenly stirred, the catalyst is evenly distributed on the surface of the carrier by impregnation, and the first time is dried naturally for 5-30 minutes, and then loaded again, and dried naturally;

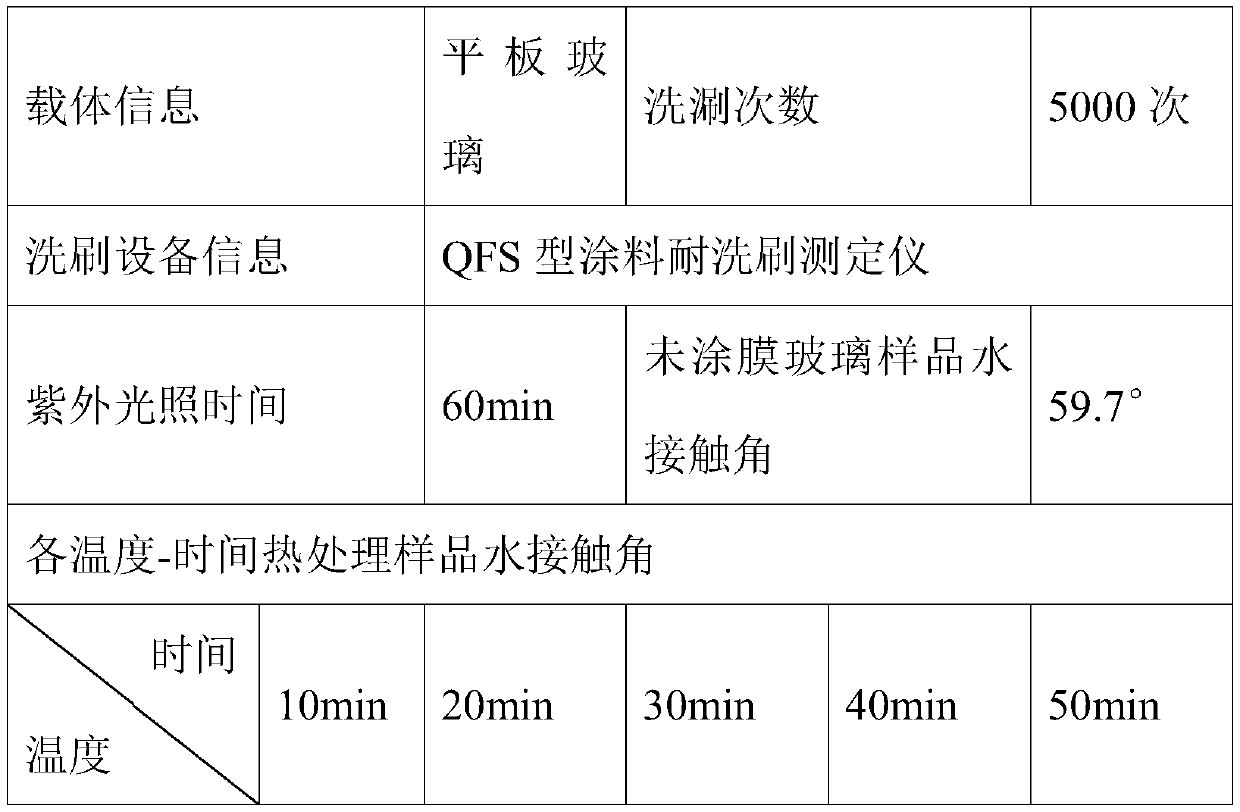

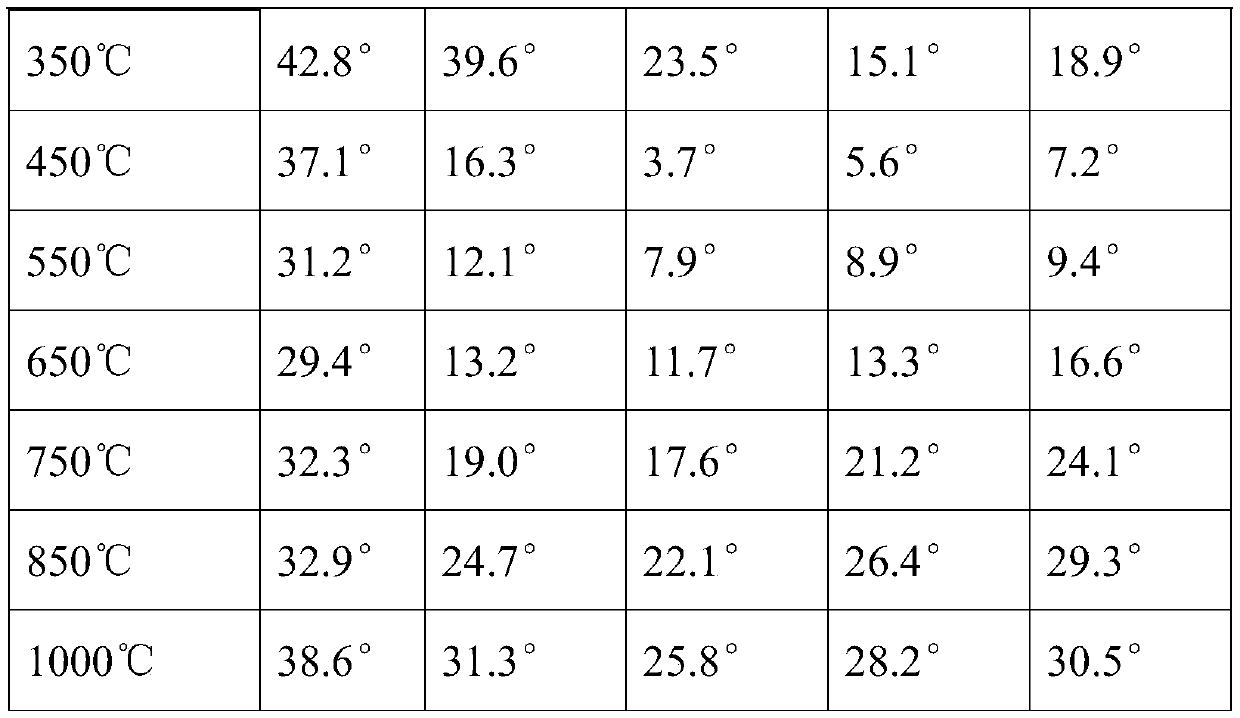

[0040] C heat treatment: temperature 450°C, heat treatment time 30min; heating rate: 10°C / min before 300°C, 5°C / min after 300°C.

[0041] D post-processing: natural cooling, after air purging, it can be filled in...

Embodiment 2

[0043] A photocatalyst loading method, comprising the steps of carrier pretreatment, catalyst loading, heat treatment, and post-treatment, specifically:

[0044] A carrier pretreatment: wash the quartz ball (tube) carrier after pretreatment and dry it at 200°C for later use; the carrier pretreatment method is to mechanically grind the carrier, and the pressure of the grinding disc is 55kPa; after grinding, perform polishing treatment, and first use HF for soaking Treat for 15s, then add H at a concentration of 3mol / L 2 SO 4 deal with.

[0045] B catalyst loading: modified TiO 2 After the catalyst is evenly stirred, the catalyst is evenly distributed on the surface of the carrier by spraying, and the first time is dried naturally for 5-30 minutes, and then loaded again, and dried naturally;

[0046] C heat treatment: temperature 400°C, heat treatment time 50min; heating rate: 10°C / min before 300°C, 5°C / min after 300°C.

[0047] D post-processing: natural cooling, after air ...

Embodiment 3

[0049] A photocatalyst loading method, comprising the steps of carrier pretreatment, catalyst loading, heat treatment, and post-treatment, specifically:

[0050] A. Carrier pretreatment: The glass ball (tube) carrier is pretreated, washed and dried at 200°C for later use; the carrier pretreatment method is to mechanically grind the carrier, and the pressure of the grinding disc is 50kPa; after grinding, it is polished, first using HF Soak for 20s, then add H at a concentration of 2mol / L 2 SO 4 deal with.

[0051] B catalyst loading: modified TiO 2 After the catalyst is evenly stirred, the catalyst is evenly distributed on the surface of the carrier by impregnation, and the first time is dried naturally for 5-30 minutes, and then loaded again, and dried naturally;

[0052] C heat treatment: temperature 500°C, heat treatment time 30min; heating rate: 10°C / min before 300°C, 5°C / min after 300°C.

[0053] D post-processing: natural cooling, after air purging, it can be filled i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com