Composite AuAgPd catalyst for hydrolysis and oxidation of alkynol and its preparation method

A technology of oxidation reaction and catalyst, applied in the direction of catalyst activation/preparation, preparation of organic compounds, metal/metal oxide/metal hydroxide catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

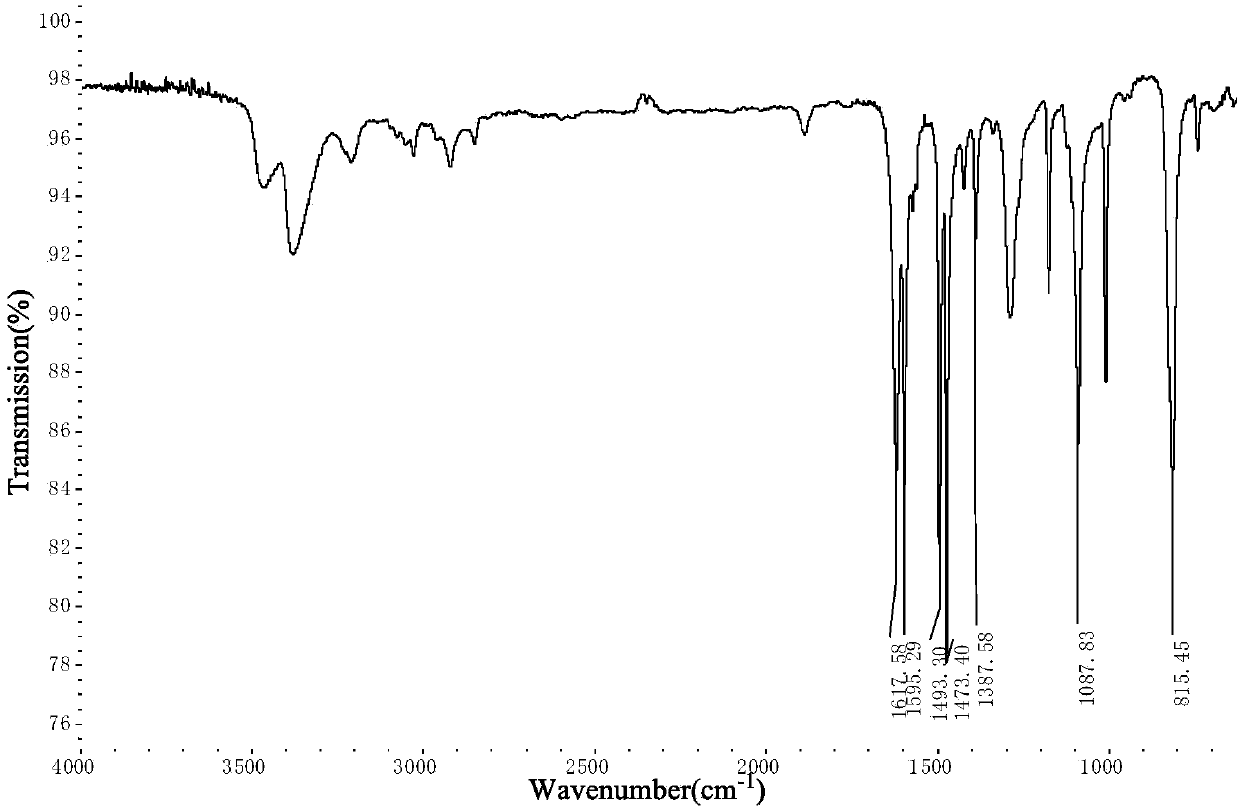

Image

Examples

Embodiment 1

[0011] Embodiment one: a kind of composite AuAgPd catalyst and preparation method for acetylenic alcohol hydrolysis and oxidation reaction comprise the following process steps: (1) AuPPh 2 Preparation of MeCl: Add appropriate amount of HAuCl to a 50 mL round bottom flask 4 (412mg, 1.0mmol), followed by an appropriate amount of EtOH (6mL). Subsequent PPh 2 Me (400 mg, 2.0 mmol) was dissolved in 20 mL of EtOH at 60 °C, and slowly added to the above mixture. It was stirred at room temperature for 24 h, and a color change was observed. The crude product was filtered under reduced pressure. Finally, the solid was dissolved and diluted with 20 mL of dichloromethane, and recrystallized with 100 mL of petroleum ether to obtain a pure solid. (2) Preparation of Au nanoparticles: AuPPh 2 MeCl (432 mg, 1.0 mmol) and dodecanethiol (10 mL) were mixed in 100 mL of toluene and a clear solution was formed. t-BuOH (741 mg, 10 mmol) was added to the above solution. The mixture was stirred...

Embodiment 2

[0012] Example 2: Apply the obtained catalyst AuAgPd@HT in the synthesis of bisphenol F: add phenol (5mmol) and AuAgPd@HT (50mg) into the reaction vessel, add 20mL tetrahydrofuran, stir at room temperature, and slowly add 37% formaldehyde solution, stir evenly, then add a certain amount of 10% hydrochloric acid solution, and heat to 50°C. The reaction time was 12 hours. After the reaction, the obtained reaction solution was separated into layers, and the oil layer was the crude reaction product. At the same time, the composite catalyst AuAgPd@HT can be recovered by filtration. The obtained crude product is rotary evaporated to recover the solvent, and the remaining phenol is recovered by vacuum distillation to obtain 4,4 dihydroxydiphenylmethane.

Embodiment 3

[0013]Example 3: Apply the obtained catalyst AuAgPd@HT in the hydrolysis of acetylenic alcohol: add phenylalkynol (1 mmol) and AuAgPd@HT (50 mg) into the reaction vessel, add 10 mL of tetrahydrofuran, stir at room temperature for 10 minutes, and then add 1mL of water, then heated to react at 60°C. The reaction time was 12 hours. After the reaction, the product was obtained with a yield of 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com