Gantry type numerically controlled cutting machine

A cutting machine, gantry technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of inaccurate cutting position of the plate, damage to the health of users, shortened service life, etc., and achieve stable and stable structural design and automation. High-level, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

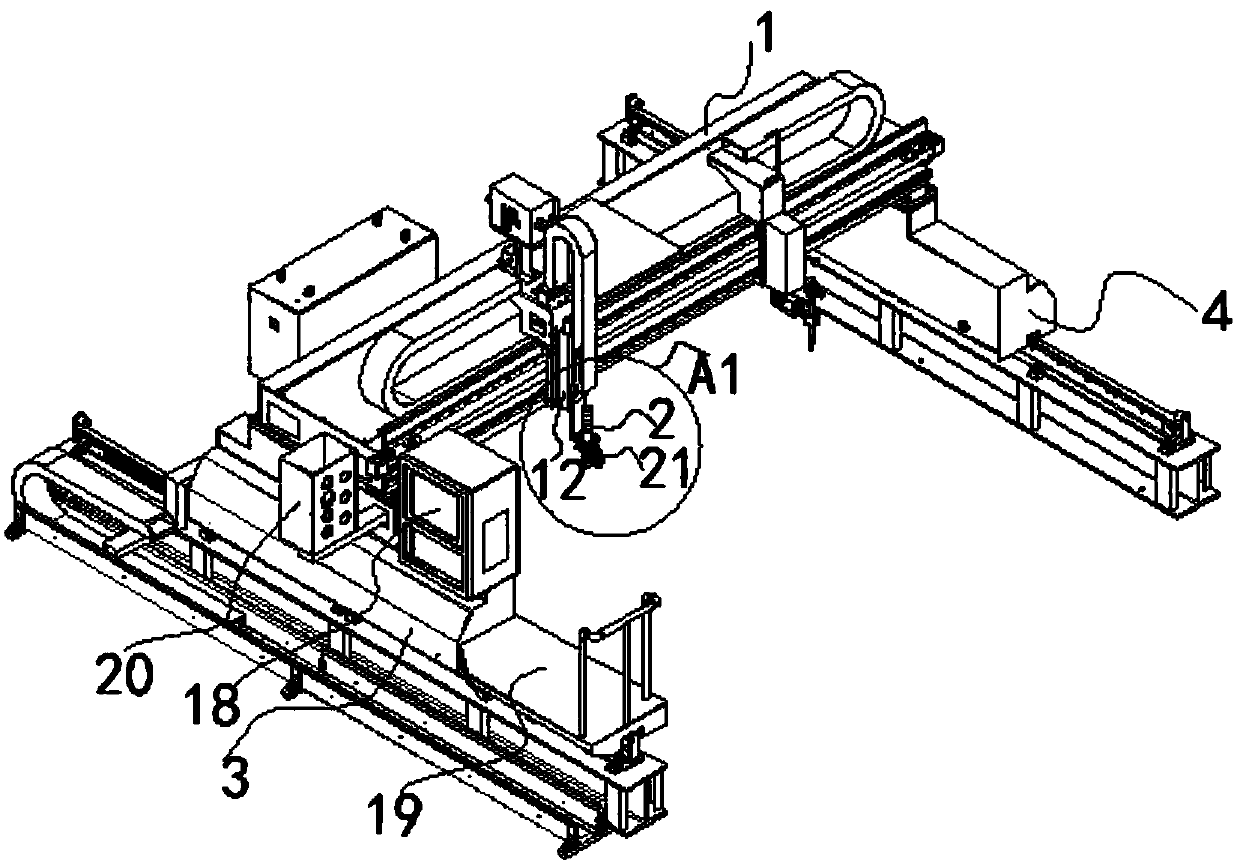

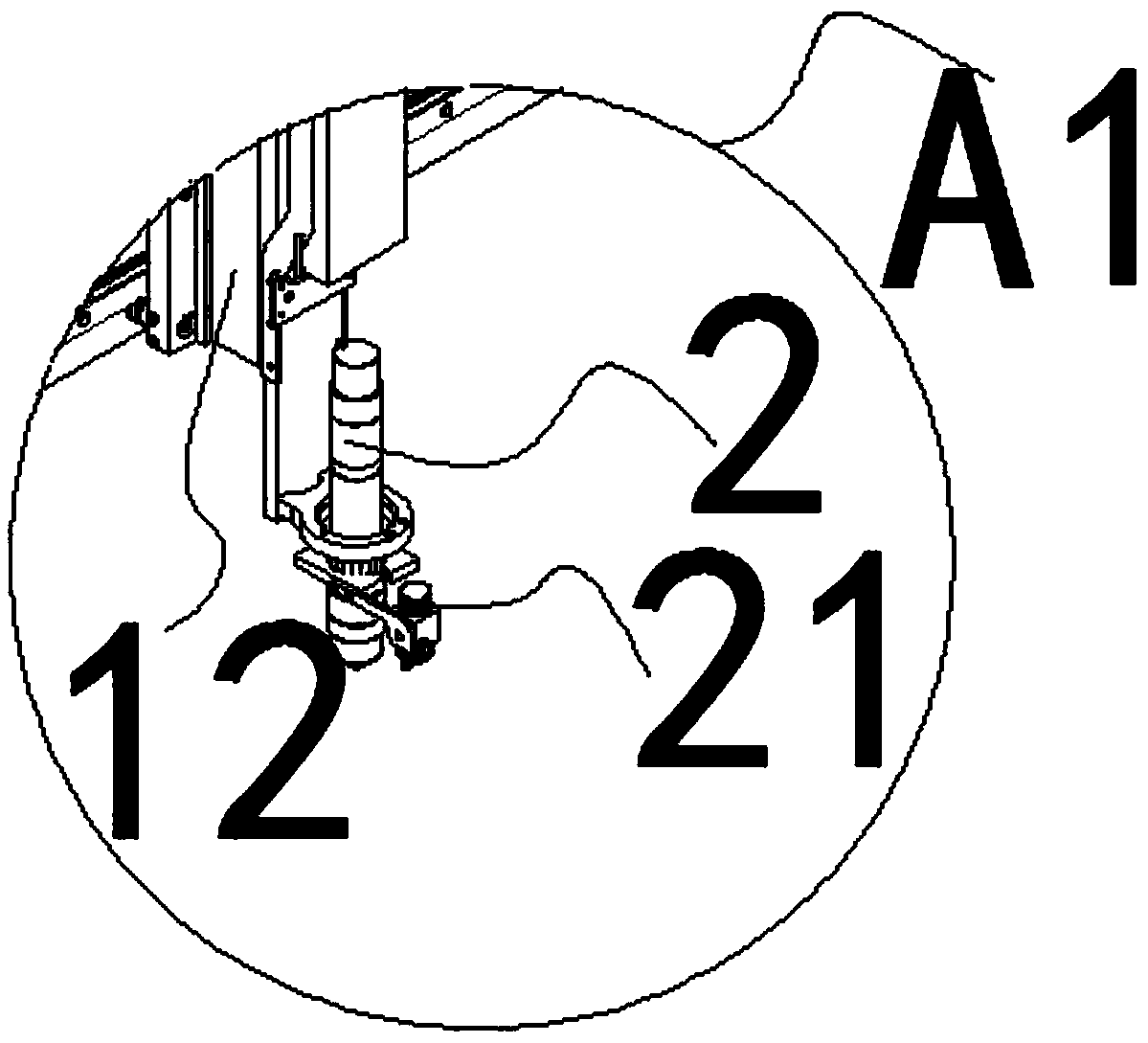

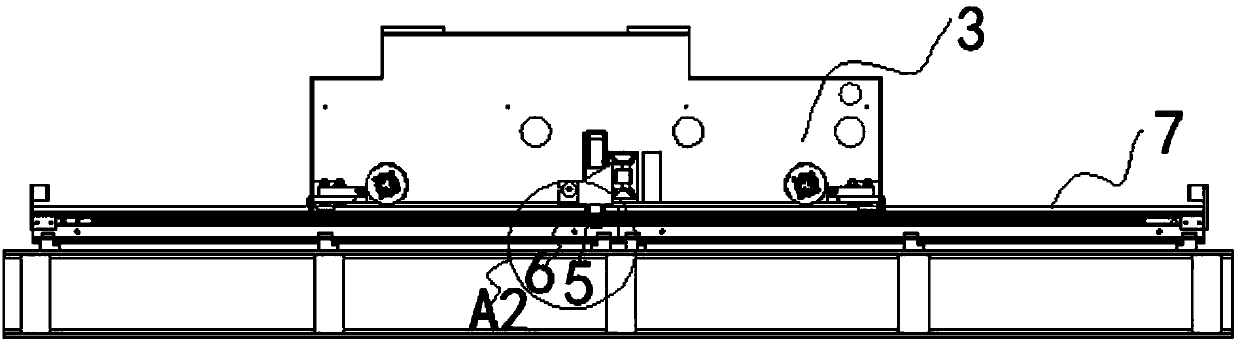

[0046] Embodiment 1: a kind of gantry type numerical control cutting machine, as Figure 1-Figure 10 As shown, it is used to cut plates, including a frame, a beam 1 and at least one cutting torch 2, the frame includes a main frame 3 and a sub-frame 4, and the two ends of the beam are respectively connected to the main frame and the sub-frame , the cutting gun is installed on the beam, and the length direction of the frame is defined as the longitudinal direction, and the cutting machine also includes a longitudinal drive mechanism for driving the frame to move longitudinally, a transverse drive mechanism for driving the cutting gun to move laterally, and a drive mechanism for driving the cutting gun to lift Lifting mechanism and spraying mechanism;

[0047] The longitudinal driving mechanism is arranged on the frame, and the longitudinal driving mechanism includes a first gear 5, a first rack 6, a first motor and a first track 7, and the first gear and the first rack are meshe...

Embodiment 2

[0063] Embodiment 2: a kind of gantry type numerical control cutting machine, as Figure 11-Figure 12 As shown, its structure is basically the same as that of Embodiment 1, except that the cutting torch is a rotary head cutting torch 17.

[0064] The gun head of the rotary head cutting gun rotates left and right in the vertical plane.

[0065] The gun head of the rotary head cutting gun rotates around the vertical circle.

[0066] The working principle of the present invention is as follows:

[0067] In the present invention, the workpiece to be cut is placed on the workbench, the cutting machine is started, and under the control of the control system, the first motor of the longitudinal drive mechanism drives the beam through the rack and pinion structure to drive the cutting torch to move longitudinally along the first track, and the horizontal drive The second motor of the mechanism drives the mounting seat of the cutting gun to drive the cutting gun to move laterally thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com