Bi-directional flexible lifting platform and tunnel cleaning vehicle

The technology of a lifting platform and a telescopic mechanism is applied in the direction of lifting frames, cleaning methods and appliances, cleaning methods using liquids, etc., which can solve problems such as the limitation of the extension width, and achieve the advantages of making up for deficiencies, occupying a small space, and having an ingenious and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described below with reference to the drawings and embodiments:

[0027] A tunnel cleaning vehicle includes a two-way telescopic lifting platform. The two-way telescopic lifting platform is directly installed on the tunnel cleaning vehicle without installing outriggers. The self-weight of the tunnel cleaning vehicle can ensure the stability of the two-way telescopic lifting platform and the safety of operation .

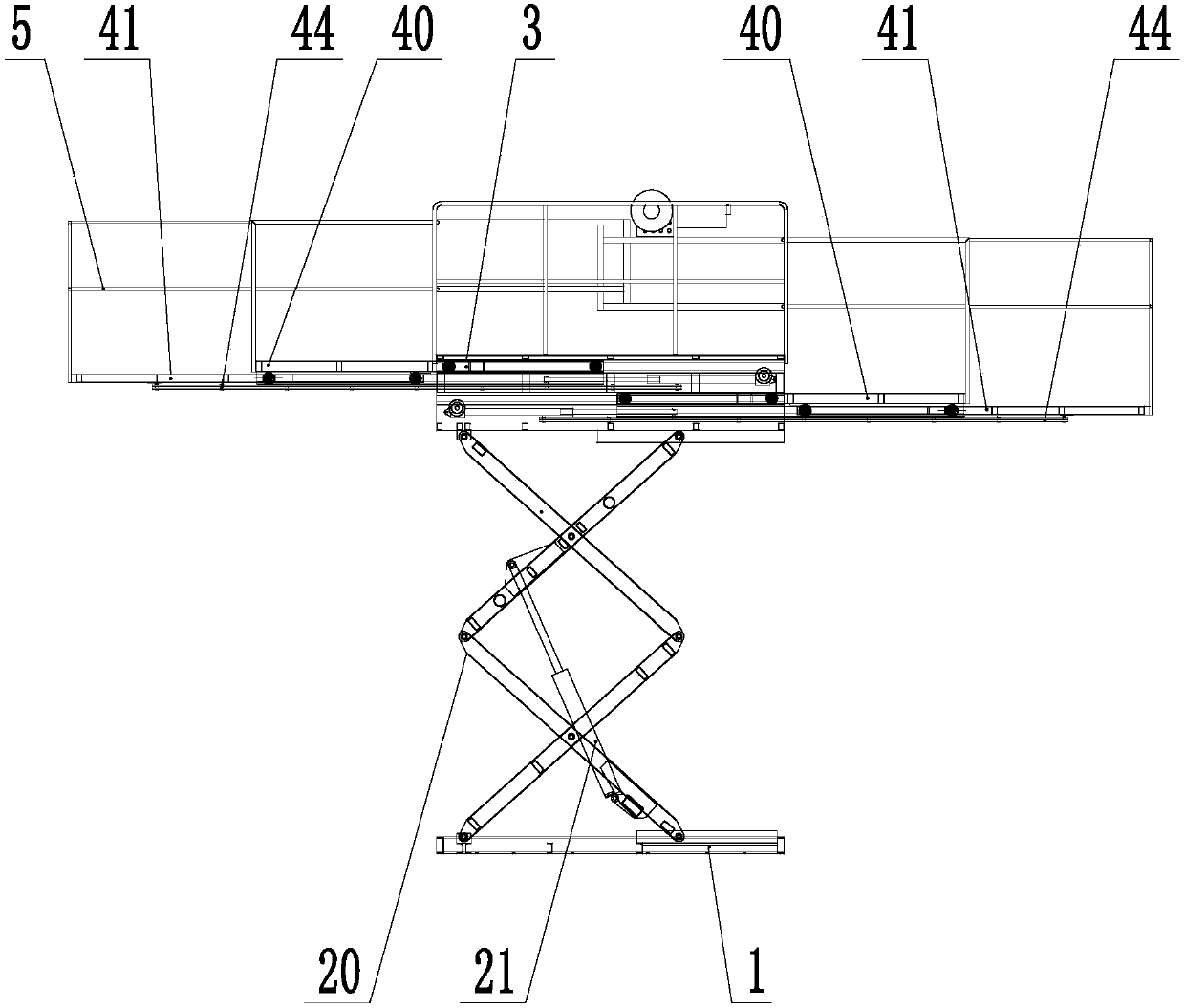

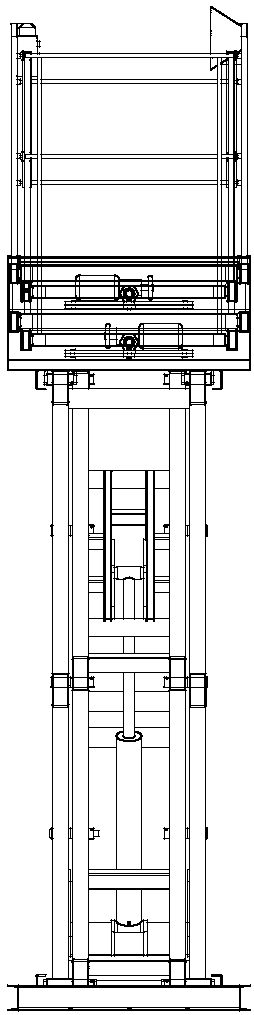

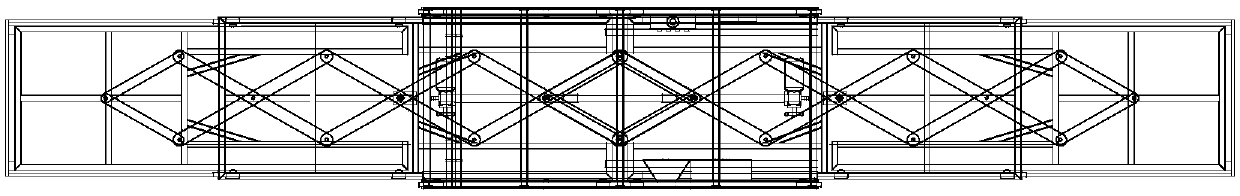

[0028] Such as Figure 1a , 1b , 1c shows: the two-way telescopic lifting platform includes a base 1, a lifting mechanism connected to the base 1, a middle table 3 connected to the lifting mechanism, a telescopic working table connected to the middle table, and a telescopic working table connected to The telescopic mechanism that drives the telescopic action. The following is a detailed description of each part:

[0029] The base 1 is welded by channel steel and rectangular tube.

[0030] The lifting mechanism includes a scissor assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com