Synthesis method of nano sapo-34 molecular sieve, sapo-34 molecular sieve catalyst and application thereof

A technology of SAPO-34 and molecular sieve, which is applied in the field of molecular sieves, can solve the problems of limiting molecular mass transfer process, large particle size of molecular sieves, unfavorable MTO catalytic reaction results, etc., and achieves the effects of increased selectivity, prolonged catalyst life, and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In the present invention, preferably, the synthetic method of described nanometer SAPO-34 molecular sieve comprises following synthetic steps:

[0037] a) After dissolving functionalized organosilane in water, sequentially add aluminum source, phosphorus source, organic amine and additional silicon source (ie organic silicon source or inorganic silicon source) to obtain a mixture with the following molar ratio (wherein The addition amount of functionalized organosilane and the additional silicon source is SiO 2 In terms of moles, the amount of phosphorus source added is P 2 o 5 In terms of moles, the amount of aluminum source added is Al 2 o 3 in moles):

[0038] SiO 2 :P 2 o 5 :Al 2 o 3 : Organic amine: H 2 O=0.2~1.2: 0.5~1.5: 0.6~1.4: 1.5~5.5: 50~200;

[0039]b) crystallize the mixture obtained in step a) at 150-220° C. for 0.4-10 days;

[0040] c) After the crystallization of the step b) is completed, the solid product is separated, washed and dried to ob...

Embodiment 1

[0063] The molar proportions of each raw material, crystallization conditions and elemental composition of the samples are shown in Table 1. The specific batching process is as follows:

[0064] 9.28g PiSi-3 and 71.40g deionized water were mixed and stirred for 1 hour, and 135.64g pseudoboehmite (Al 2 o 3 Mass percentage composition 72.5%), 34.58g phosphoric acid (H 3 PO 4 85% by mass), 20.24g of triethylamine and 8.33g of tetraethyl orthosilicate, and then stirred and aged for 24 hours, and then the gel mixture was transferred to a stainless steel reactor. The molar ratio of each component in the synthesis system is 0.8SiO 2 : 1.5P 2 o 5 : 0.8Al 2 o 3 :2TEA:80H 2 O, the molar ratio of PiSi-3 to ethyl orthosilicate is 1:1.

[0065] After putting the reaction kettle into the oven, the temperature was programmed to rise to 200°C, and the static crystallization was carried out for 48 hours. After the reaction, the solid product was centrifuged, washed repeatedly with d...

Embodiment 2~12

[0079] The specific batching ratio and crystallization conditions are shown in Table 1, and the specific batching process is the same as in Example 1.

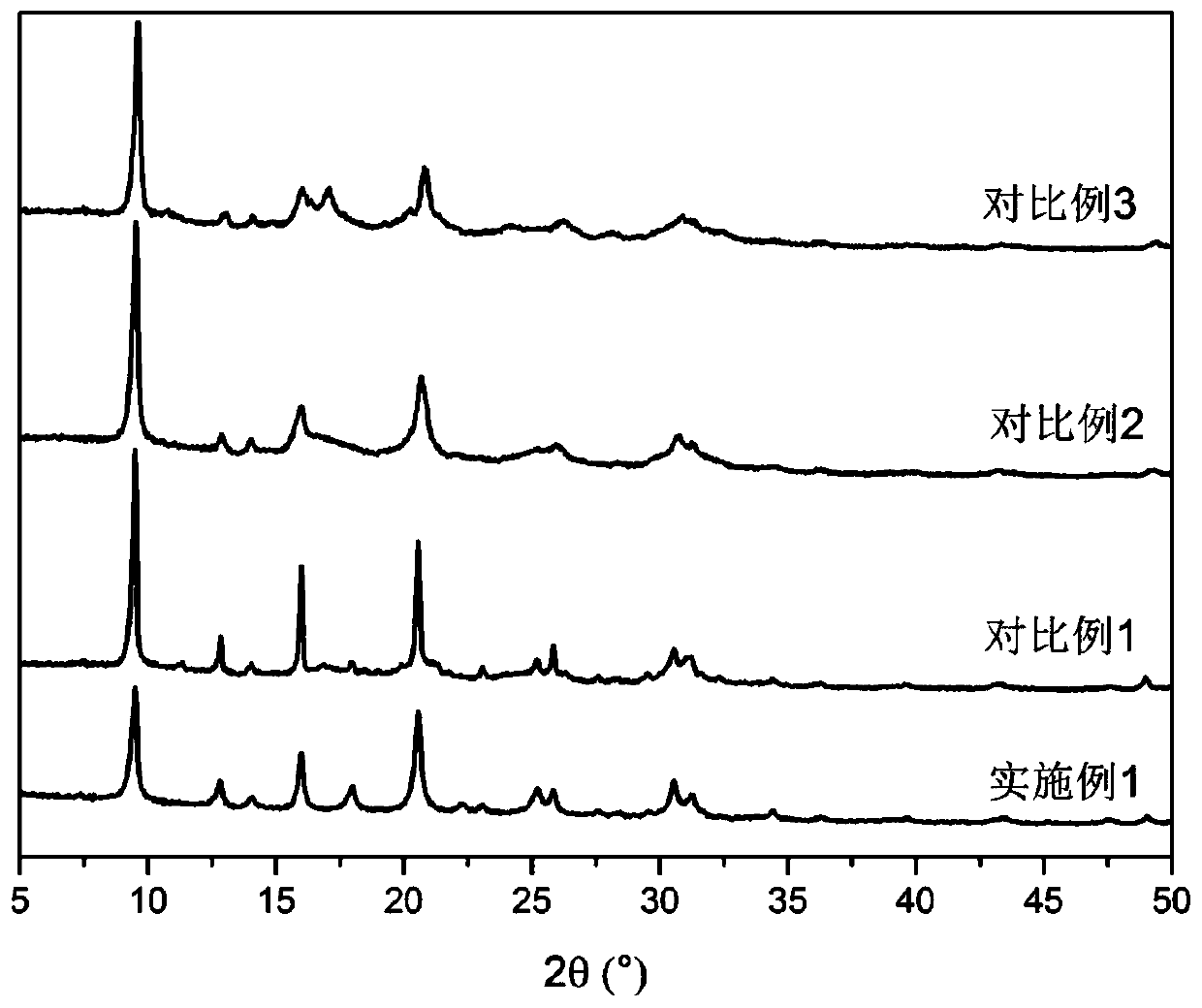

[0080] Carry out XRD analysis to embodiment 2~12 gained sample, data result is close to table 2, namely peak position and shape are identical, according to the variation of synthetic conditions, the relative peak intensity of peak fluctuates in ± 10% scope, shows that synthetic product has SAPO Features of -34 structures.

[0081] XRF elemental composition analysis was performed on the samples obtained in Examples 2-12, and the results are shown in Table 1.

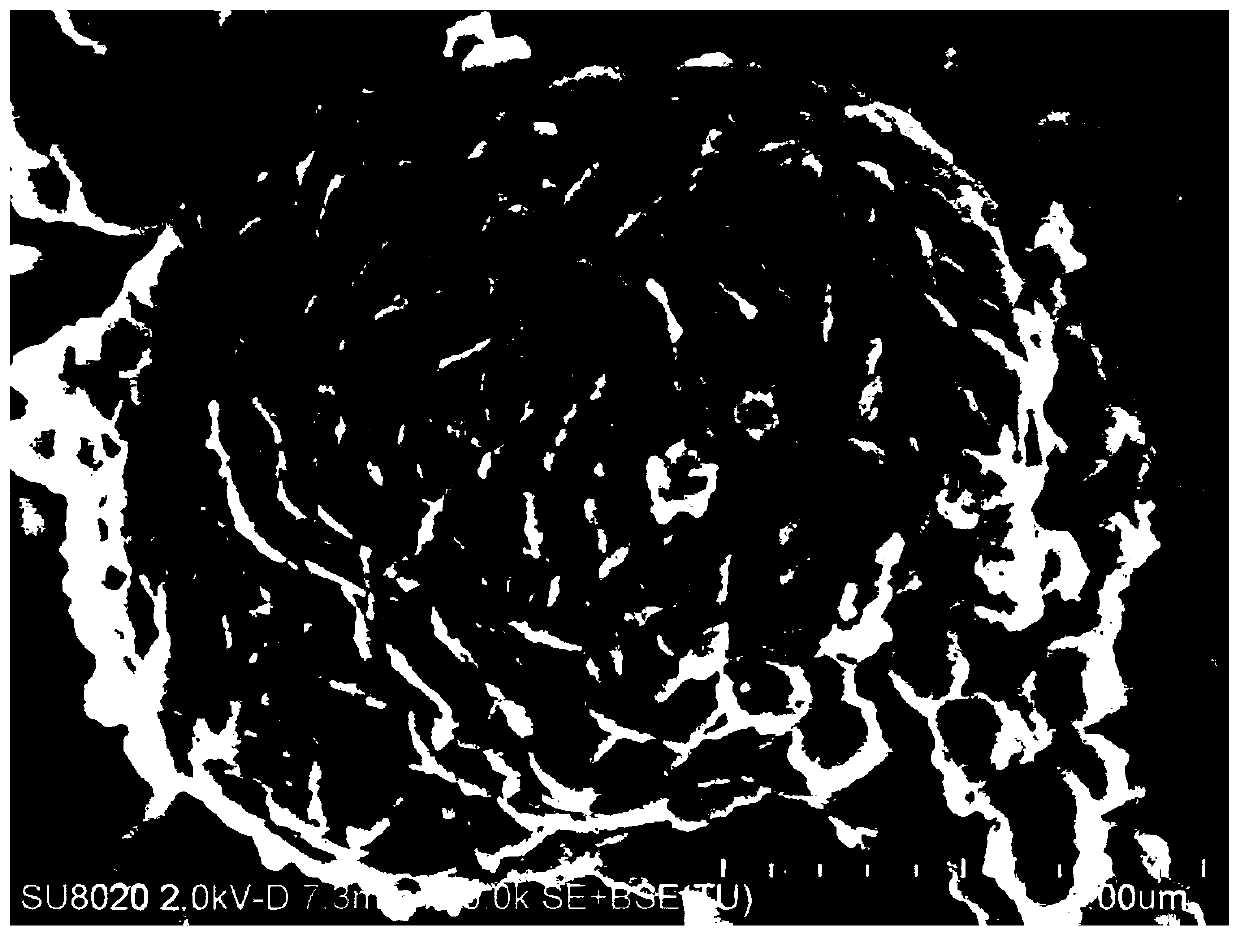

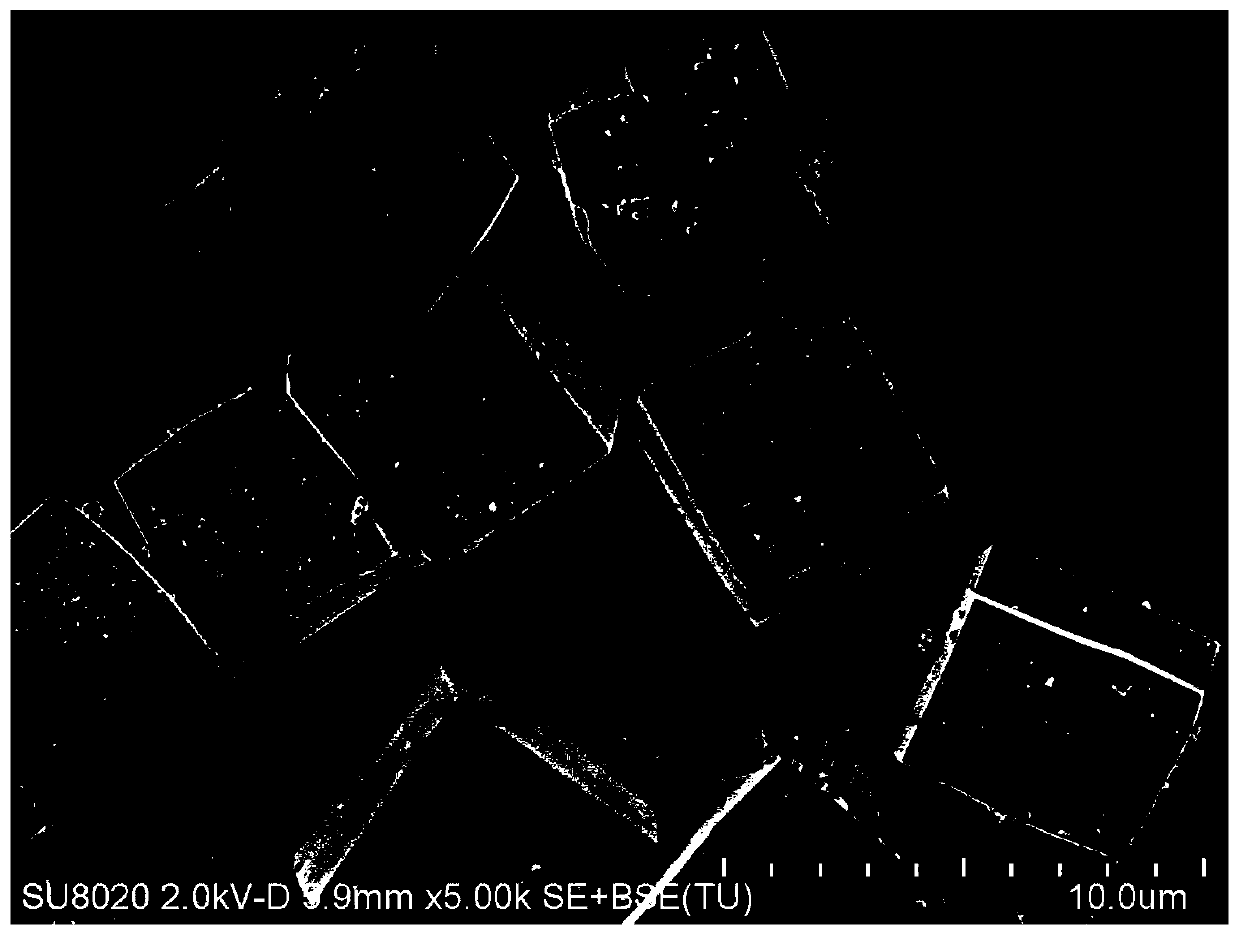

[0082] Adopt scanning electron microscope to analyze the morphology of embodiment 2~12 gained sample, gained electron micrograph is all with figure 1 resemblance.

[0083] Table 1: Molecular sieve synthesis ingredients, crystallization conditions and elemental composition

[0084]

[0085] Table 2: XRD results of the samples obtained in Example 1

[0086]

[0087]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap