Rare earth mother liquid dewatering device

A dewatering device and mother liquor technology, applied in the fields of metallurgical wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of easy falling of rare earth, poor dehydration effect, waste and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

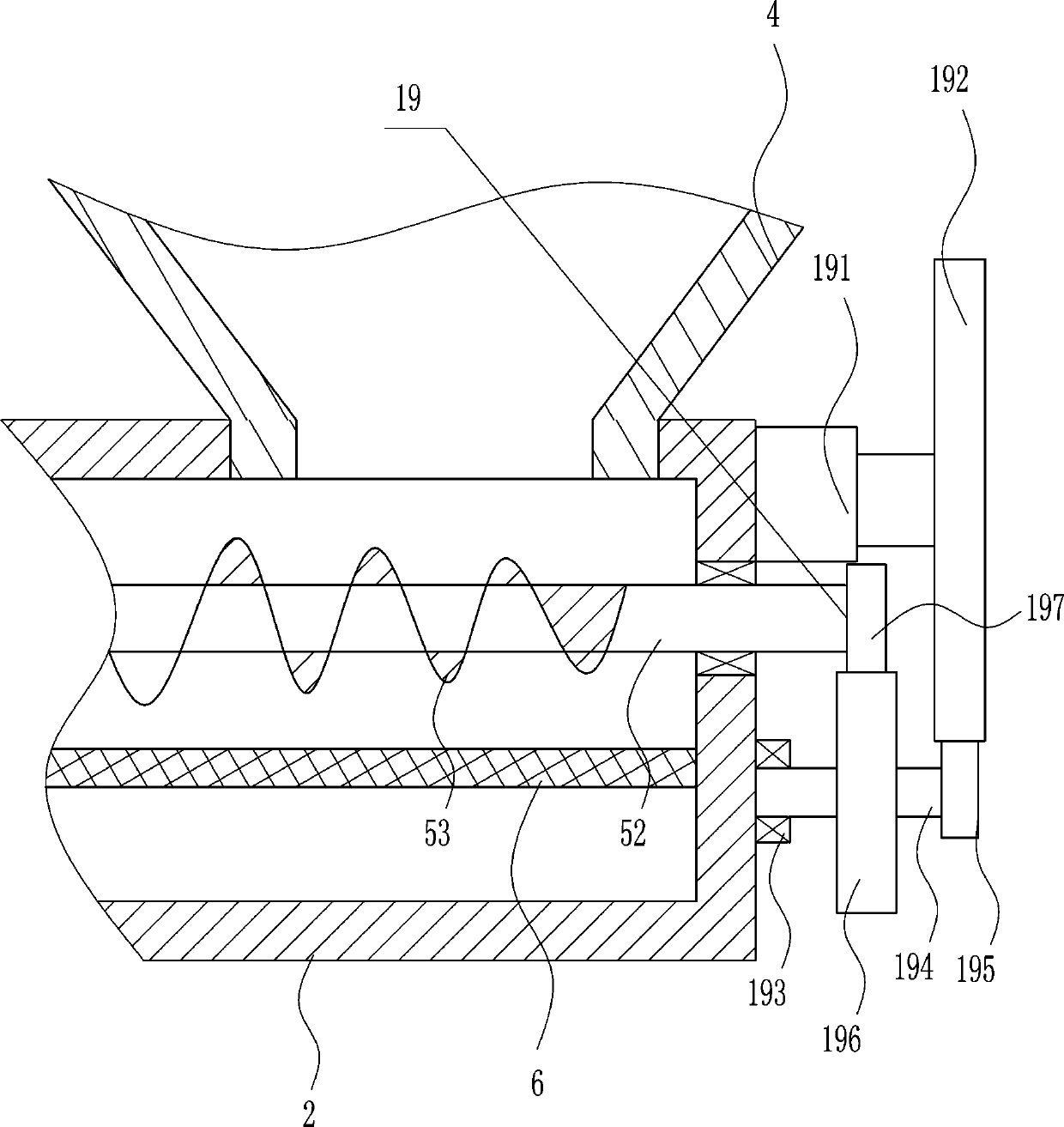

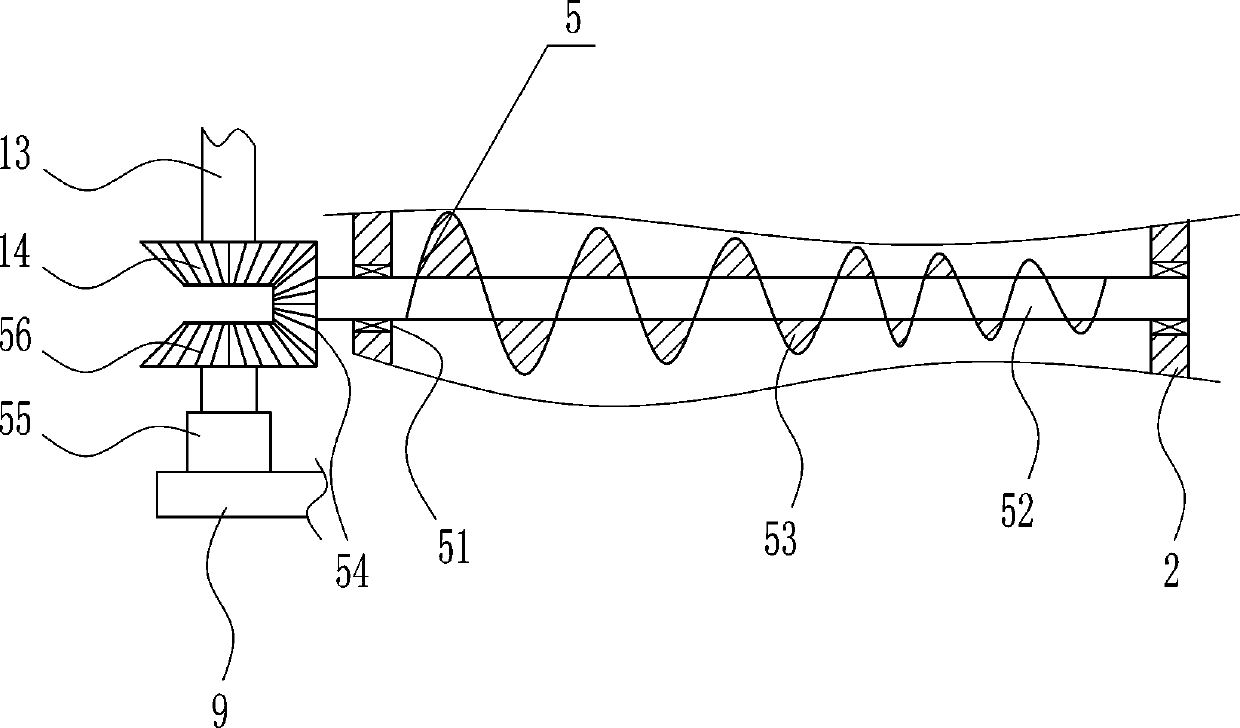

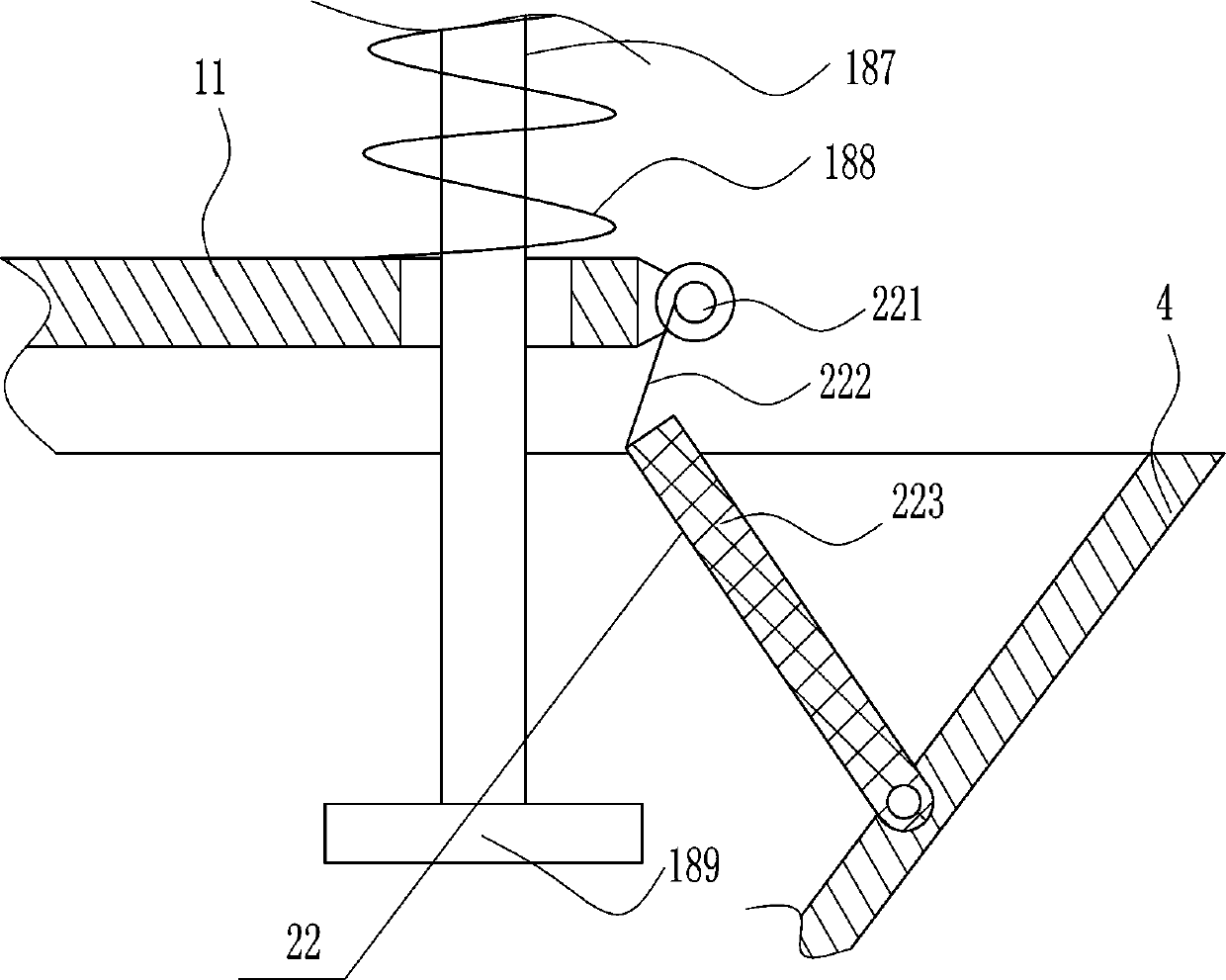

[0039] A rare earth mother liquor dehydration device, such as Figure 1-9 As shown, it includes a leg 1, a box body 2, a first bevel gear 3, a lower hopper 4, a rotating device 5, a screen frame 6, a discharge pipe 8, a horizontal plate 9, a vertical rod 10, a fixed plate 11, a second Bearing seat 12, first rotating shaft 13, fourth bevel gear 14, vertical plate 15, third bearing seat 16, second rotating shaft 17 and pushing device 18, the outer bottom of box body 2 is equipped with supporting legs 1 symmetrically on the left and right sides , there is a discharge port 7 in the middle of the bottom of the box body 2, a screen frame 6 is arranged inside the box body 2, the screen frame 6 is located above the discharge port 7, the screen frame 6 is connected to the inner side of the box body 2, and the left side of the bottom of the box body 2 A discharge pipe 8 is connected, and the discharge pipe 8 communicates with the inside of the box body 2. The discharge pipe 8 is located...

Embodiment 2

[0041] A rare earth mother liquor dehydration device, such as Figure 1-9 As shown, it includes a leg 1, a box body 2, a first bevel gear 3, a lower hopper 4, a rotating device 5, a screen frame 6, a discharge pipe 8, a horizontal plate 9, a vertical rod 10, a fixed plate 11, a second Bearing seat 12, first rotating shaft 13, fourth bevel gear 14, vertical plate 15, third bearing seat 16, second rotating shaft 17 and pushing device 18, the outer bottom of box body 2 is equipped with supporting legs 1 symmetrically on the left and right sides , there is a discharge port 7 in the middle of the bottom of the box body 2, a screen frame 6 is arranged inside the box body 2, the screen frame 6 is located above the discharge port 7, the screen frame 6 is connected to the inner side of the box body 2, and the left side of the bottom of the box body 2 A discharge pipe 8 is connected, and the discharge pipe 8 communicates with the inside of the box body 2. The discharge pipe 8 is located...

Embodiment 3

[0044] A rare earth mother liquor dehydration device, such as Figure 1-9As shown, it includes a leg 1, a box body 2, a first bevel gear 3, a lower hopper 4, a rotating device 5, a screen frame 6, a discharge pipe 8, a horizontal plate 9, a vertical rod 10, a fixed plate 11, a second Bearing seat 12, first rotating shaft 13, fourth bevel gear 14, vertical plate 15, third bearing seat 16, second rotating shaft 17 and pushing device 18, the outer bottom of box body 2 is equipped with supporting legs 1 symmetrically on the left and right sides , there is a discharge port 7 in the middle of the bottom of the box body 2, a screen frame 6 is arranged inside the box body 2, the screen frame 6 is located above the discharge port 7, the screen frame 6 is connected to the inner side of the box body 2, and the left side of the bottom of the box body 2 A discharge pipe 8 is connected, and the discharge pipe 8 communicates with the inside of the box body 2. The discharge pipe 8 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com