Silicon oil shock absorber

A technology of shock absorber and silicone oil, which is applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problems of difficult production and processing, and achieve the effect of reasonable quantity, light weight and improved damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

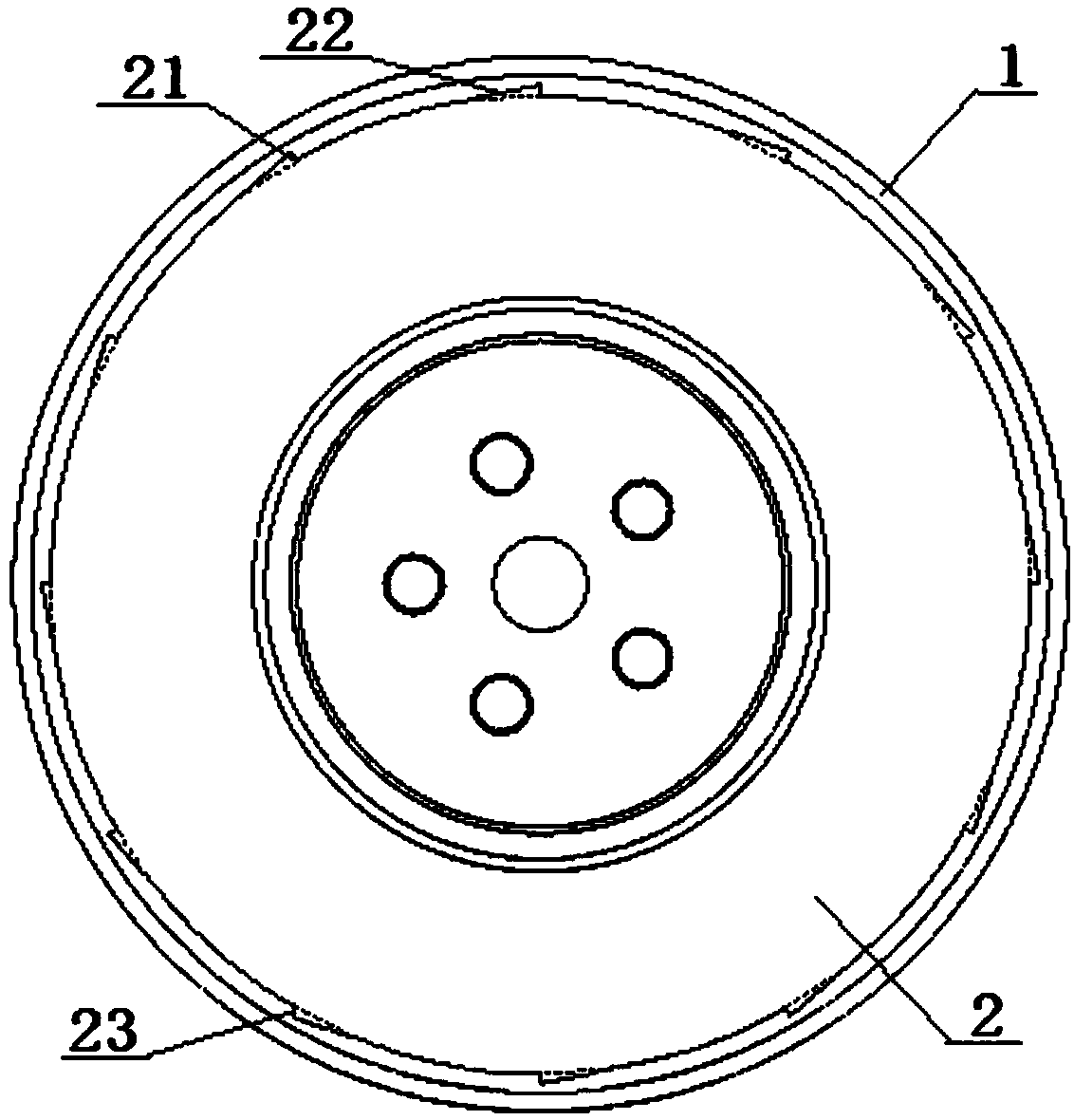

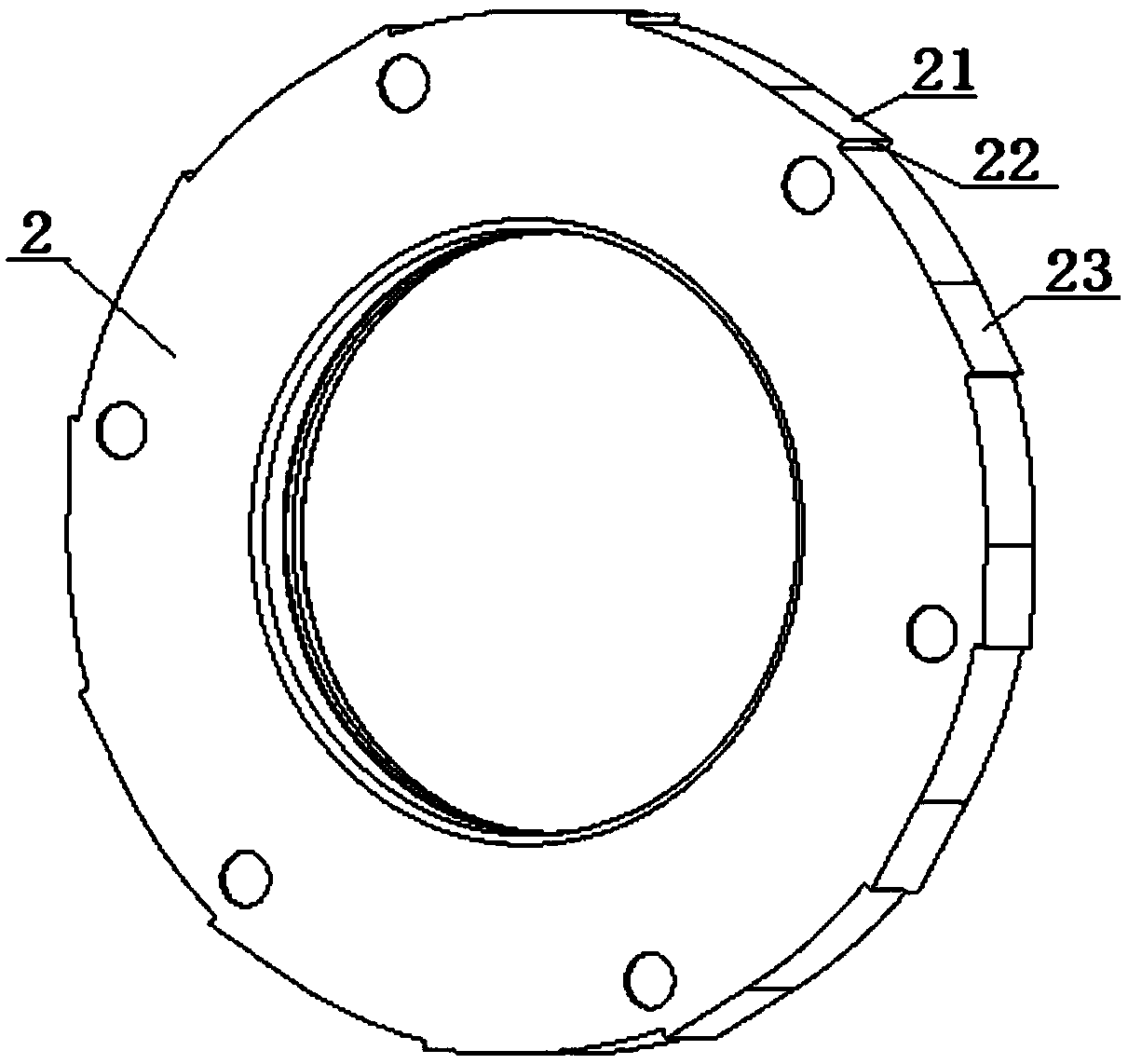

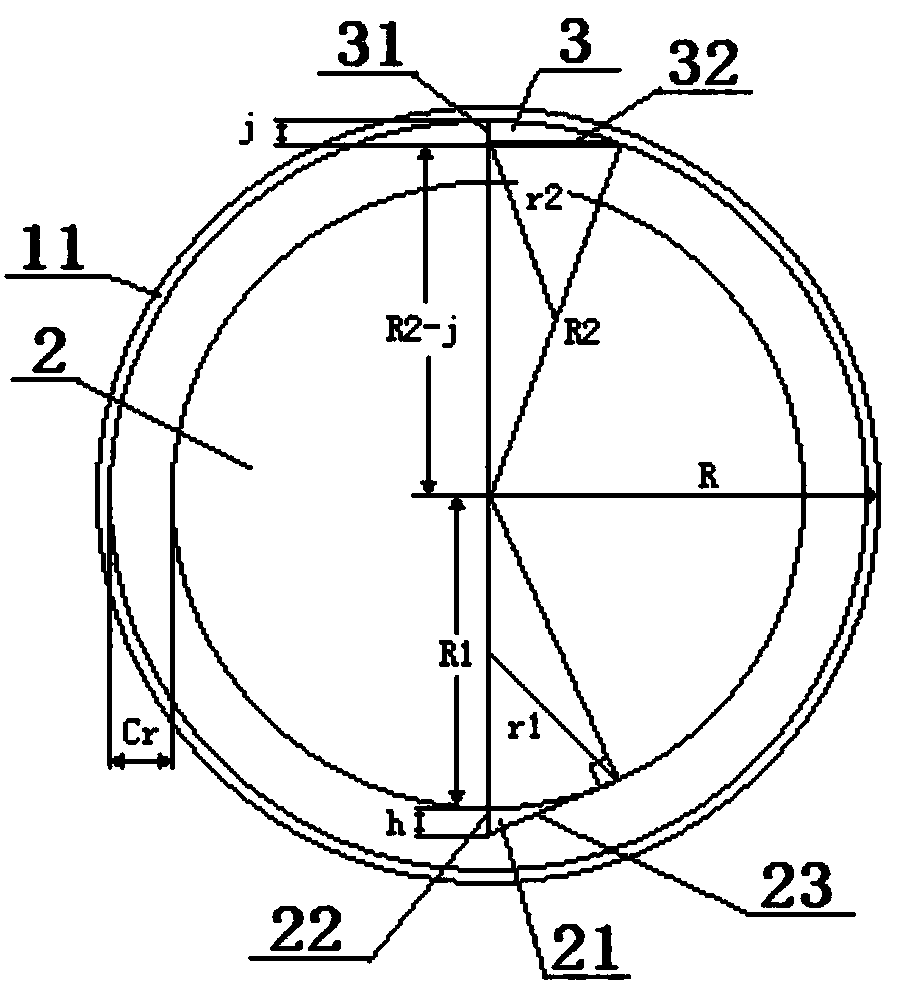

[0071] see figure 1 – Figure 4 , a silicone oil shock absorber, including a housing 1 and an inertia ring 2, the inertia ring 2 is arranged inside the housing 1; the inertia ring 2 is a ring structure, and the section of the inertia ring 2 along its radial direction is rectangular structure, the outer circumference of the inertia ring 2 is evenly distributed with n damping teeth 21, n is an integer greater than or equal to 2; the distance from the tip of the damping teeth 21 to the outer circumference of the inertia ring 2 is h, h The value range is 2mm-15mm, the two sides of the damping teeth 21 are formed with a damping surface 22 and a buffer surface 23, the buffer surface 23 is tangent to the outer circumferential surface of the inertia ring 2; the damping surface 22 and the inertia ring 2, the tangent plane at the intersection of the damping surface 22 and the inertia ring 2 is perpendicular to the damping surface 22.

[0072] The formula for calculating the stiffness ...

Embodiment 2

[0079] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0080] Twelve or sixteen damping teeth 21 are evenly distributed on the outer circumference of the inertia ring 2 .

Embodiment 3

[0082] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0083] see Figure 5 , the damping surface 22 is a concave arc surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com