Rust-proof gear

A technology of gears and gear bodies, which is applied in the direction of gear lubrication/cooling, belts/chains/gears, components with teeth, etc. It can solve the problems of shortening the service life of gears, increasing design and manufacturing costs, and aggravating gear surface wear, etc., to achieve Extended service life, simple structure, improved friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

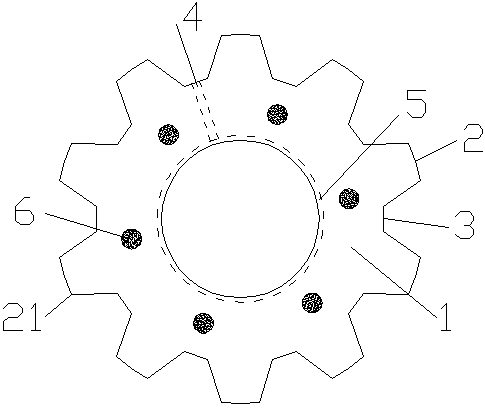

[0014] Such as figure 1 As shown, a rust-proof gear includes a gear main body 1, the gear main body 1 is provided with external teeth 2, and an external tooth groove 3 is arranged between the external teeth 2 and the external teeth 2, and the external tooth groove The end of 3 is provided with an oil injection hole 4 from the outside to the inside, and an oil groove 5 is provided on the inside of the inner hole of the gear main body 1, and the oil injection hole 4 communicates with the oil groove 5, and several Through holes 6, each through hole 6 is provided with a nylon filler, and the outer surface of the gear body 1 is also provided with a protective layer 21, the protective layer 21 is a sulfide layer, the sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com