An evaporation tube, a combustion chamber, and an engine with a built-in swirler at the outlet

A technology of returning combustion chamber and evaporating tube, applied in the field of engine and combustion chamber, can solve the problems of inability to change the oil and gas mixture, flameout, inability to improve the residence time of high temperature gas, etc., to widen the stable working range, increase the airflow speed, and improve the fuel The effect of spatial distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

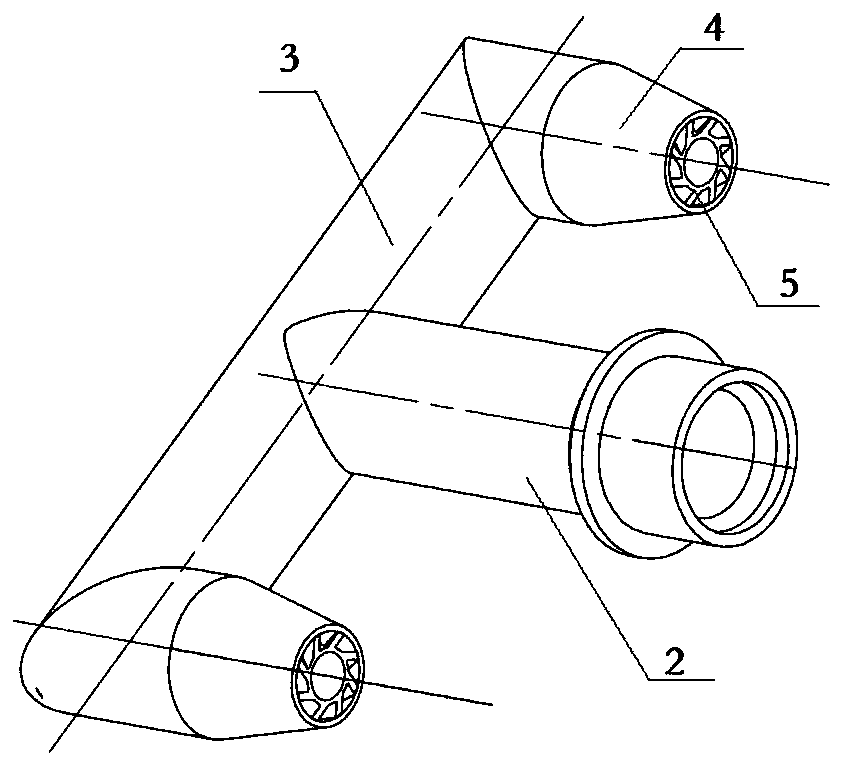

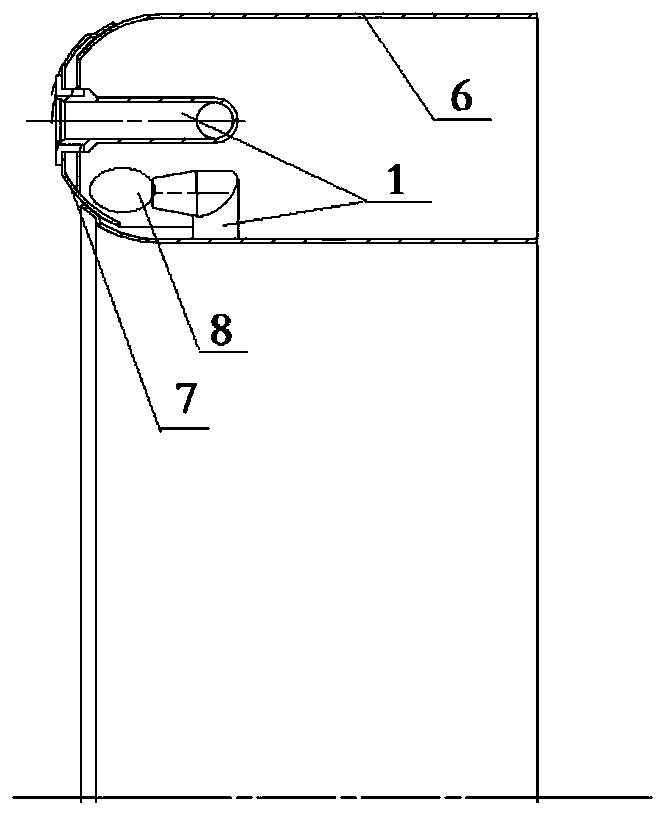

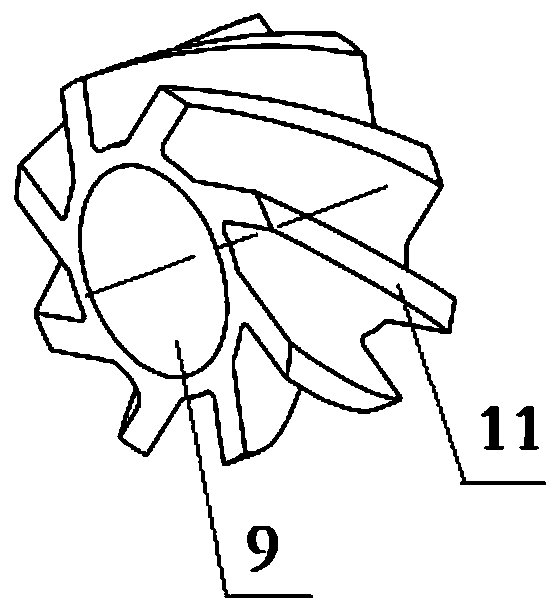

[0032] Such as figure 1 As shown, the evaporating tube with a built-in cyclone in the outlet of the present invention includes an evaporating tube inlet section 2, an evaporating tube middle section 3, an evaporating tube outlet section 4, an evaporating tube inlet section 2, an evaporating tube middle section 3, and an evaporating tube that are connected in sequence. Pipe outlet section 4 three sections constitute L type or T type ( figure 1 Shown in is the T-shaped evaporation tube structure). A cyclone 5 is built in at the outlet of the evaporating tube outlet section 4, such as image 3 As shown, the swirler 5 includes a central passage 9 and a swirl passage arranged on the peripheral periphery of the central passage by a plurality of swirl vanes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com