Integrated coupling module

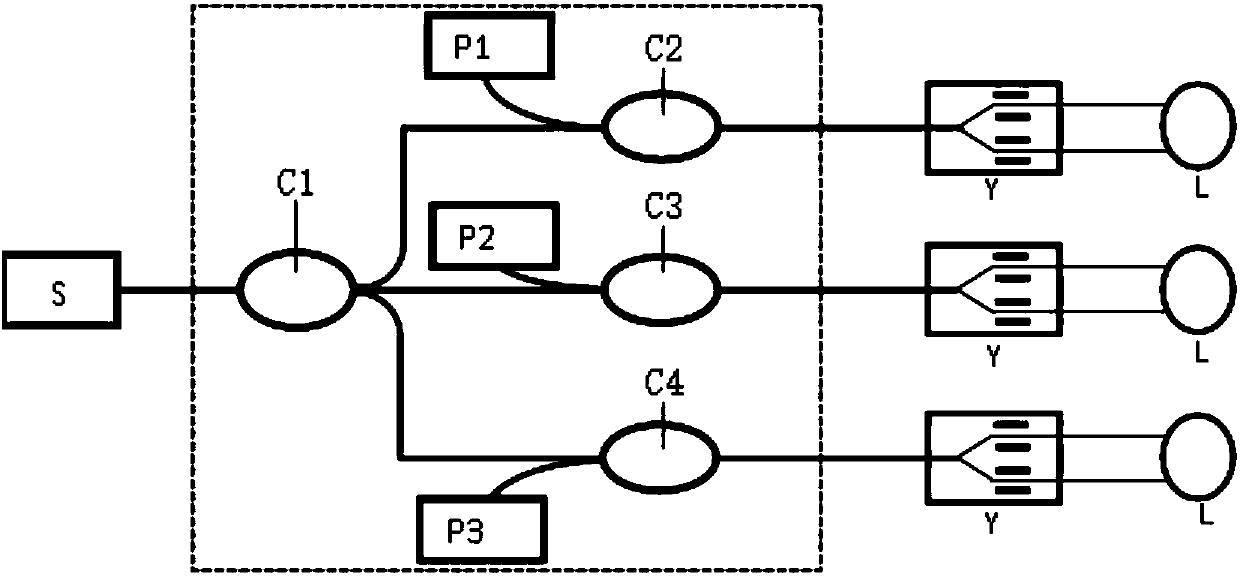

A coupling module and optical coupling technology, applied in the field of optical sensing and signal detection, can solve the problems of fiber optic gyro system and fiber optic current transformer system that cannot be miniaturized and integrated, and achieve light weight, enhanced reliability, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

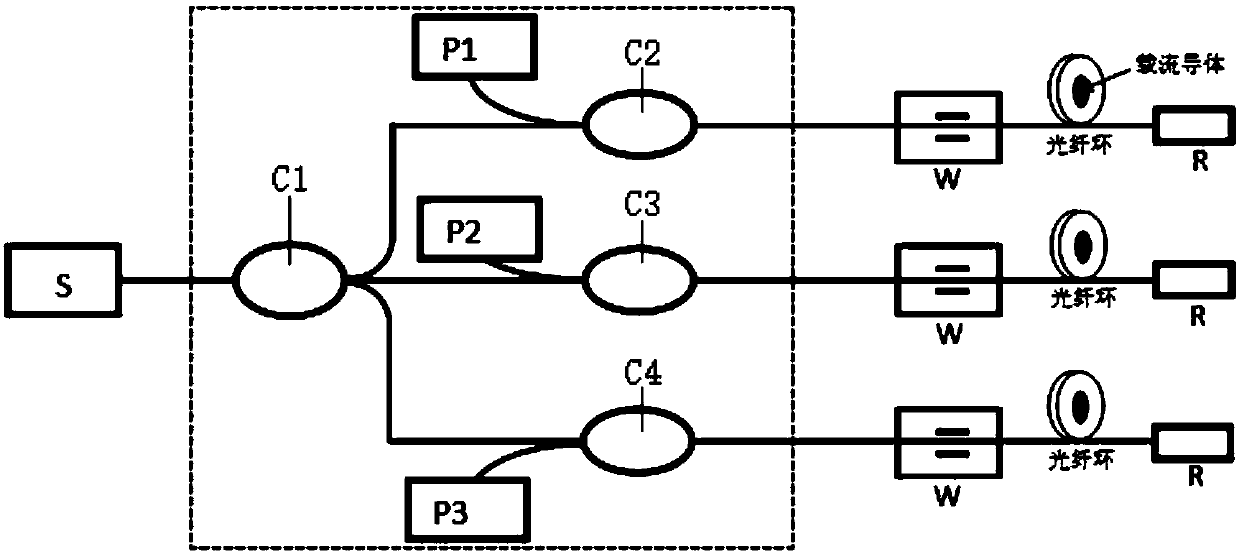

[0048] Such as image 3 and Figure 3-1 As shown, an integrated coupling module is arranged in the package shell 10, between the light source S outside the package shell and three optical path return devices, including a fiber collimator 2 and a beam splitter S1 arranged sequentially on the light path of the light source , Spectroscopic film S2 and full reflection film S3.

[0049] The integrated coupling module also includes three groups of optical coupling transmission units, each group of optical coupling transmission units includes a first optical fiber collimator, a secondary beam splitter and a second optical fiber collimator. The secondary spectroscopic sheets of the three groups of optical coupling transmission units are respectively arranged on the reflective light paths of the spectroscopic sheet S1, the spectroscopic sheet S2 and the full reflection sheet S3, and the light reflected by the spectroscopic sheet is collimated through the second optical fiber after bei...

Embodiment 2

[0058] see Figure 4 to Figure 4-3 The difference between this embodiment and Embodiment 1 is that the reflected light of the spectroscopic sheet is transmitted by the secondary spectroscopic sheet of each group of optical coupling transmission units, and then transmitted through the corresponding second optical fiber collimator and returned, and the returned light is returned again After being reflected by the second optical fiber collimator through the second optical fiber collimator, it returns to the corresponding detector through the first optical fiber collimator;

[0059] The second optical fiber collimator 4, the second optical fiber collimator 6, and the second optical fiber collimator 8 are respectively arranged on the transmission optical path of the secondary light splitter S4, the secondary light splitter S5, and the secondary light splitter S6; The collimator 3 , the first fiber collimator 5 , and the first fiber collimator 7 are respectively arranged on the opti...

Embodiment 3

[0061] see Figures 5 to 5-3 The difference between this embodiment and Embodiment 1 is that the angle between the beam splitter S1 and the beam splitter S2 and the incident direction of the light path of the light source is 45°, and the total reflection plate S30 is arranged next to the total reflection plate S3, and the total reflection plate S3 and the light source S The included angle between the incident direction is 135°, and the included angle between the full reflection film S30 and the incident direction of the light path of the light source is 45°;

[0062] The transmitted beams of the secondary beam splitter S4 and the secondary beam splitter S5 enter the second fiber collimator 4 and the second fiber collimator 6 respectively after being reflected by the total reflection plate S3; The reflection sheet S30 enters the second fiber collimator 8 after reflection.

[0063] The package size of the whole device is 30×26×6mm, and the output positions of the optical fibers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com