Finite element modeling method for simulating failure short-circuit mechanism of pressing connection type IGBT device

A modeling method and crimping technology, applied in the fields of instruments, electrical digital data processing, special data processing applications, etc., can solve problems such as changes in characteristic parameters of crimping IGBTs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

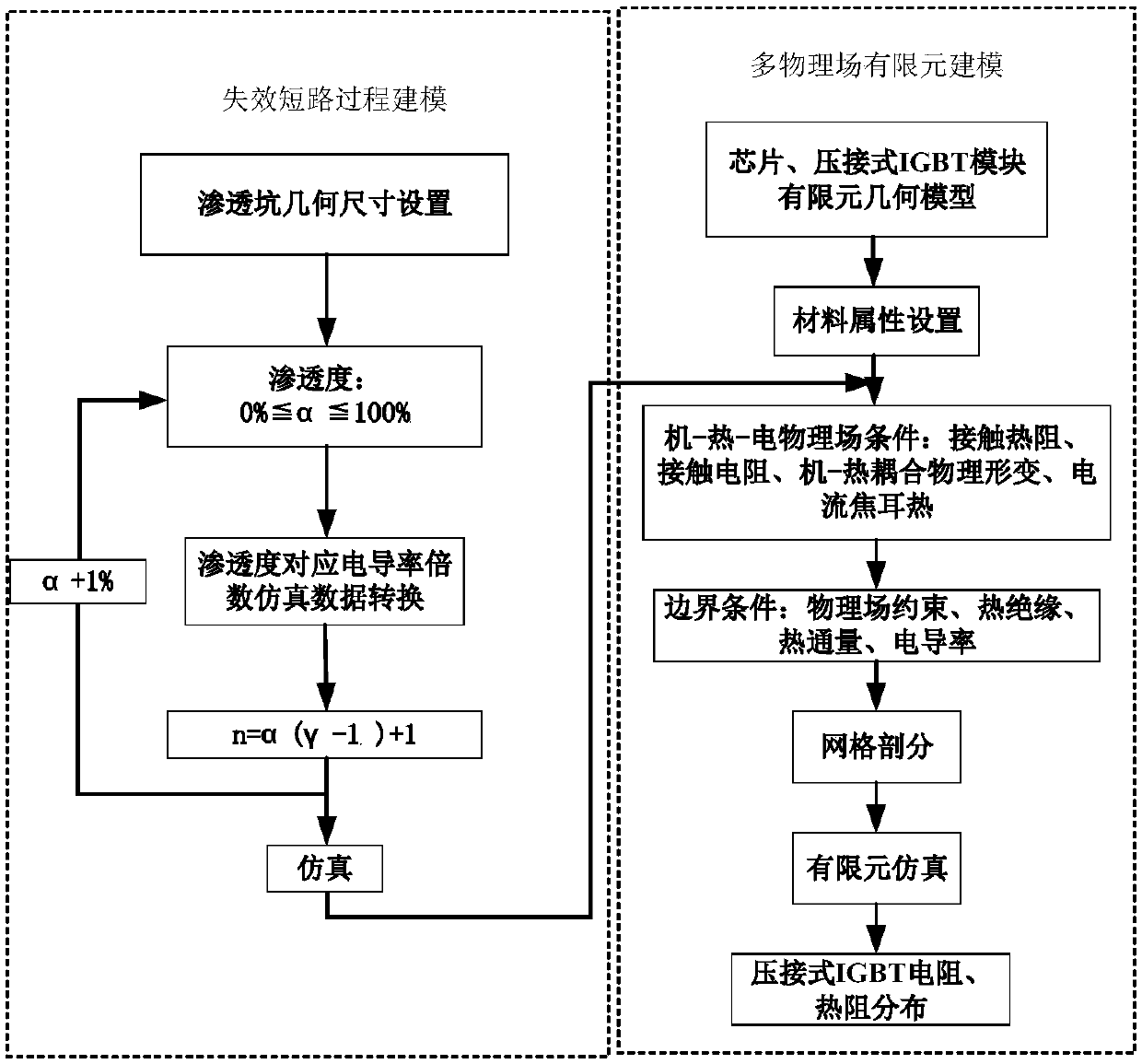

[0044] figure 1 It is a flowchart of the modeling method of the present invention, such as figure 1 As shown, the joint modeling method includes multi-physics modeling of press-fit IGBT devices and modeling of failure short-circuit seepage pits, where:

[0045] Press-connect IGBT simulates the failure short-circuit process modeling. According to the failure short-circuit mechanism of the press-connect IGBT device, the degradation model of the penetration pit on the surface of the IGBT chip is established, and the failure short-circuit process is simulated through the change of the conductivity of the penetration pit.

[0046] The specific process is: establish a failure short-circuit penetration pit model, and an IGBT chip failure short-circuit penetration pit equivalent model: calculate the different failure degrees of the penetration pit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com