Building method of full-fabricated-type house

A construction method and full assembly technology, applied in the direction of building structure, building, building type, etc., can solve the problems of complex construction and construction, reduce pollution and garbage discharge, improve the assembly rate, and solve the complex construction and construction of prefabricated buildings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

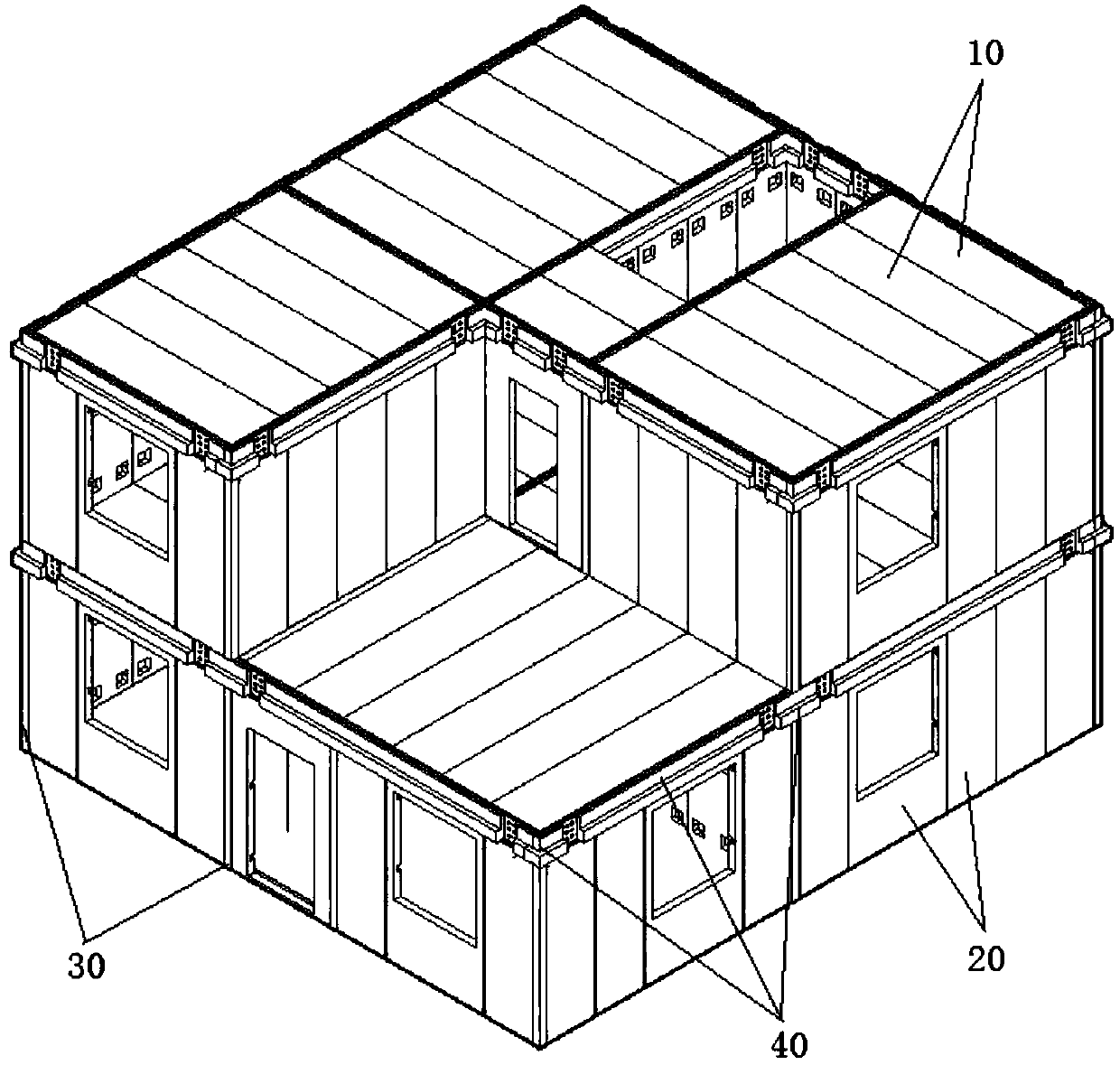

[0026] Further, as a specific embodiment of the construction method of the fully assembled house provided by the present invention, the following steps are also included:

[0027] E. Install the wall system of the N+1th floor on the connecting beam system of the Nth floor: install the wall panels 20 and the auxiliary connecting members 30 of the wall panels in sequence on the connecting beam system of the Nth floor and connect them closely to form the N+th floor 1 layer wall system;

[0028] F. Install the N+1th floor coupling beam system on the N+1th floor wall system: splice and connect the coupling beam members 40 in sequence to form the N+1th floor wall system Coupling system;

[0029] G. Install the N+1st floor slab system on the N+1st floor coupling beam system: set up the floor 10 on the shoulder surface of the coupling beam member 40 of the N+1st floor coupling beam system and connect it tightly to form the 1st floor N+1 floor system;

[0030] Wherein, N is a positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com