Efficiency optimization control method of fuel cell array system for tramcar

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, electrochemical generators, circuits, etc., can solve the problems of less research on power generation arrays, poor fuel economy, and short service life of fuel cells, so as to achieve easy digital realization and improve Efficiency, the effect of optimizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

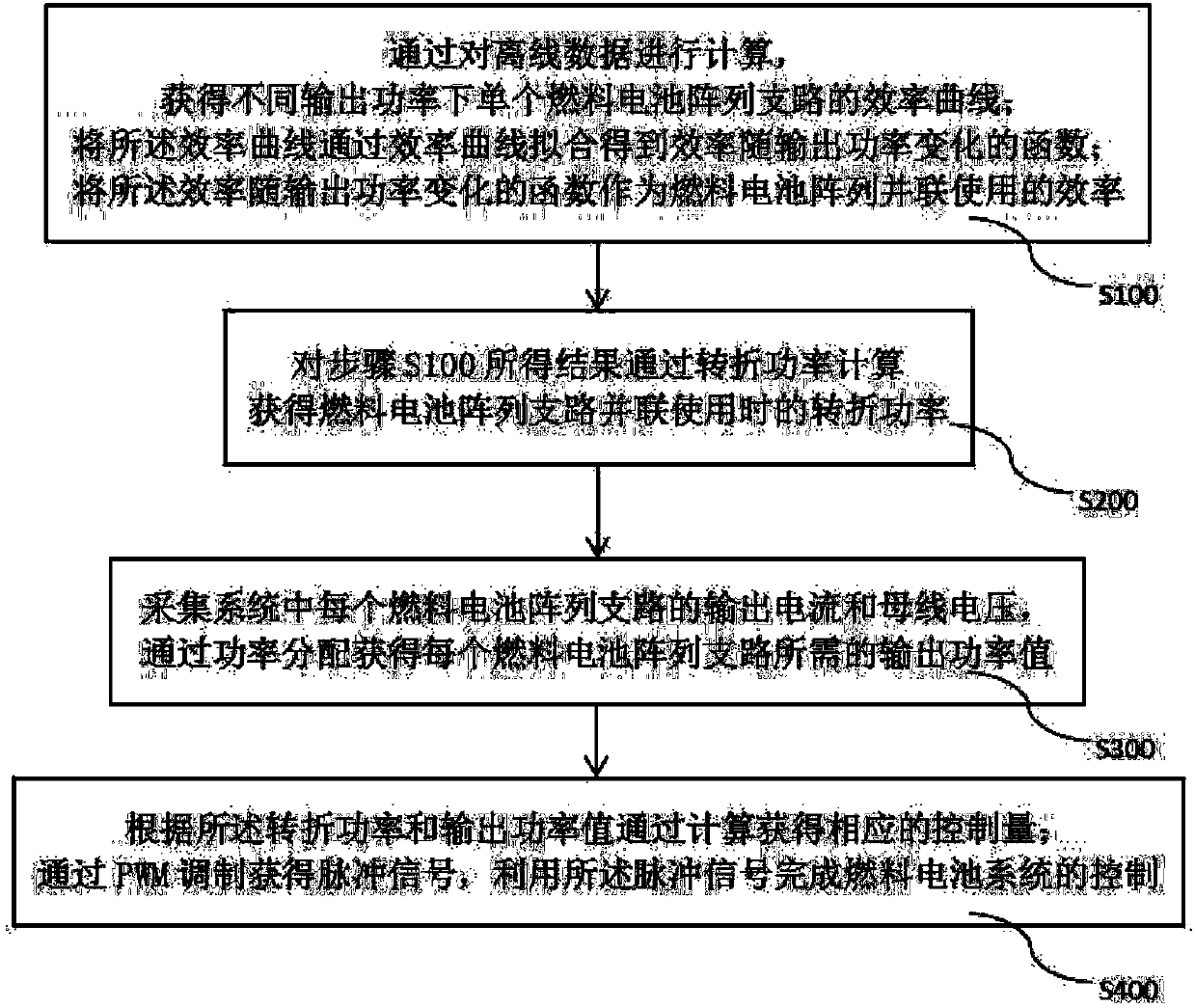

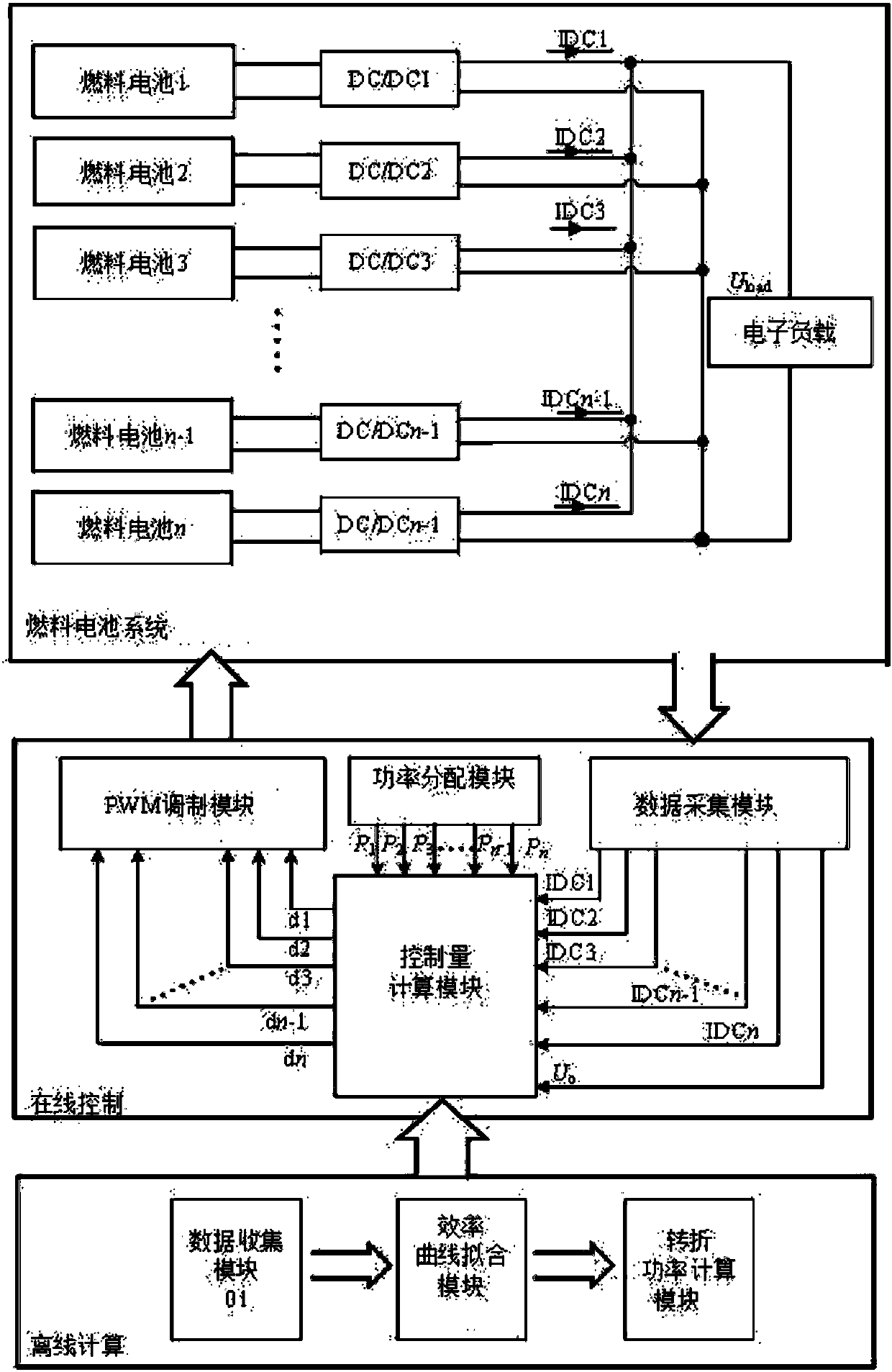

[0057] In this example, see figure 1 As shown, the present invention proposes an efficiency optimization control method for a fuel cell array system for trams, including an off-line calculation process and an on-line control process;

[0058] The off-line computing process includes steps:

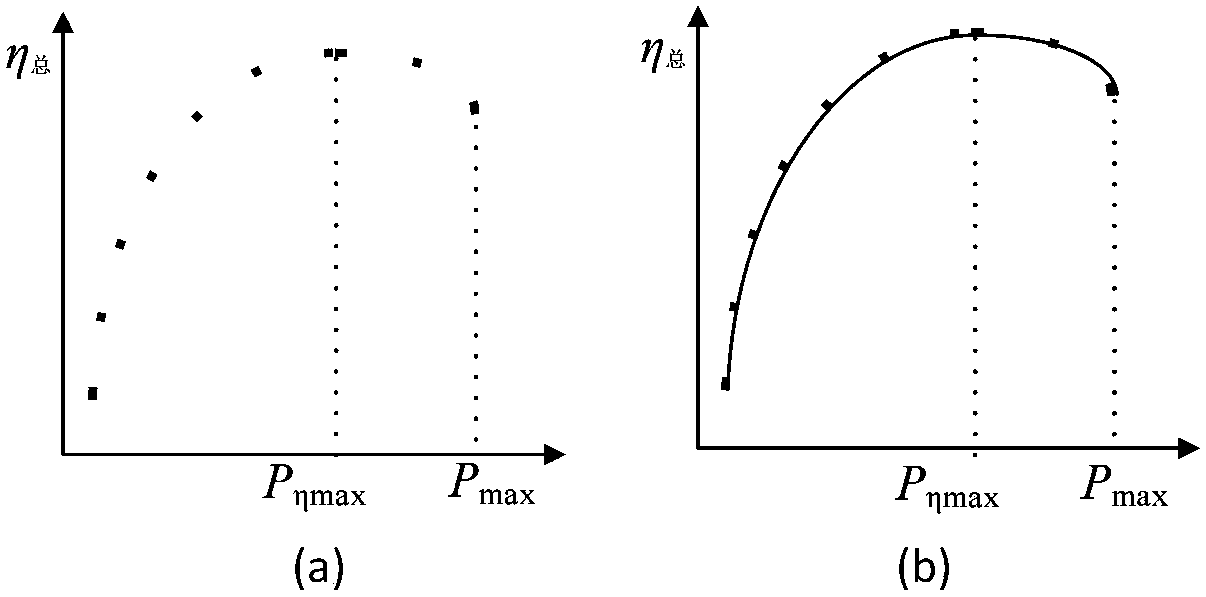

[0059] S100. Obtain the efficiency curve of a single fuel cell array branch under different output powers by calculating the off-line data; fit the efficiency curve through the efficiency curve to obtain a function of the efficiency changing with the output power; calculate the efficiency with the output power Variation as a function of the efficiency of fuel cell arrays used in parallel;

[0060] S200, calculating the breakpoint power of the fuel cell array branches used in parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com