Spraying and coating integrated shielding device

A shielding device and an integrated technology, applied in spraying devices, devices for coating liquid on the surface, coatings, etc., can solve the problem of not being able to load light-load spraying robots, it is difficult to ensure that the colloid will not be sprayed, high equipment costs and operating costs, etc. problem, to achieve the effect of improving the ability to clean the colloid, improving the effect of squeegeeing, and improving the efficiency of gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

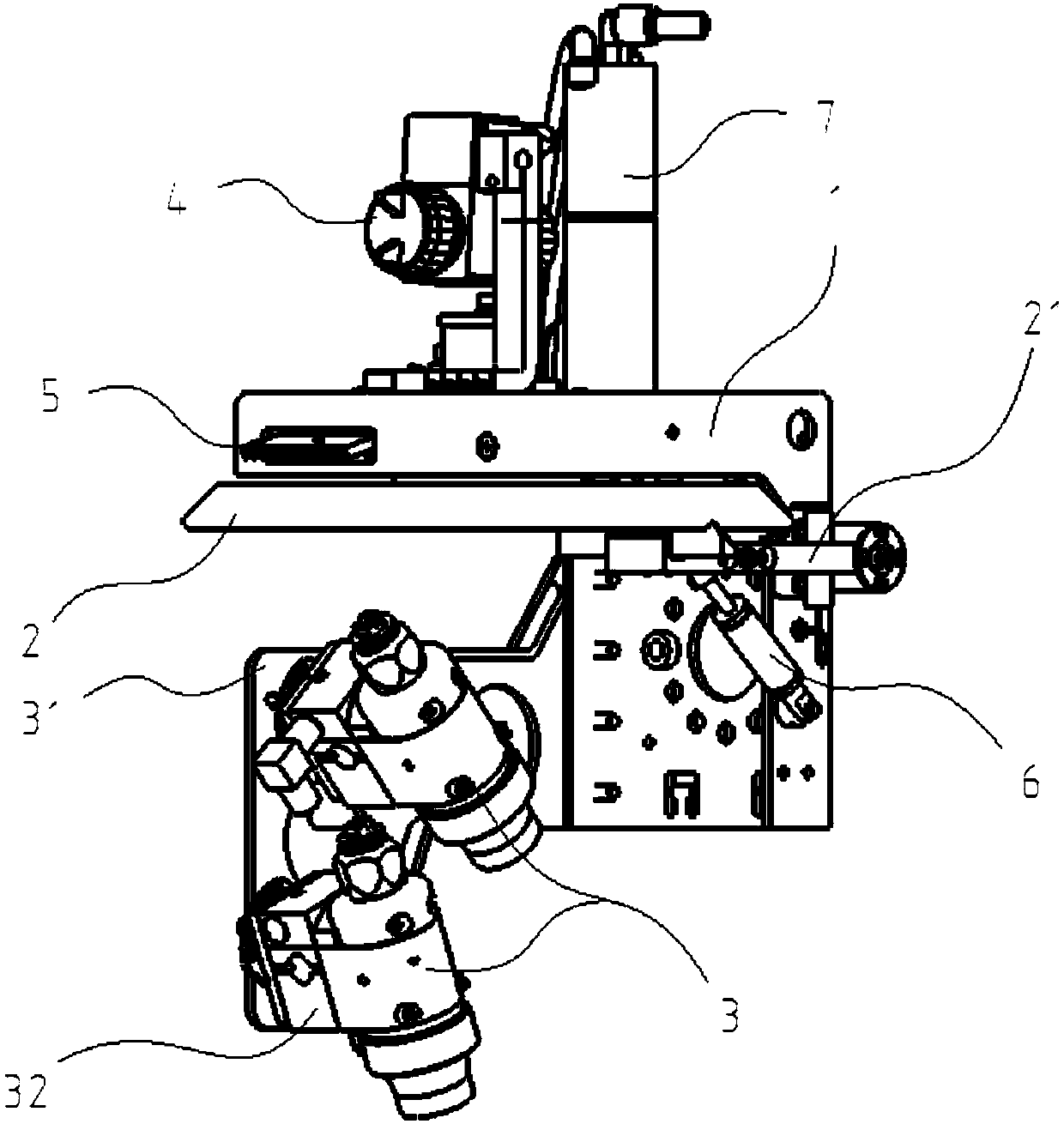

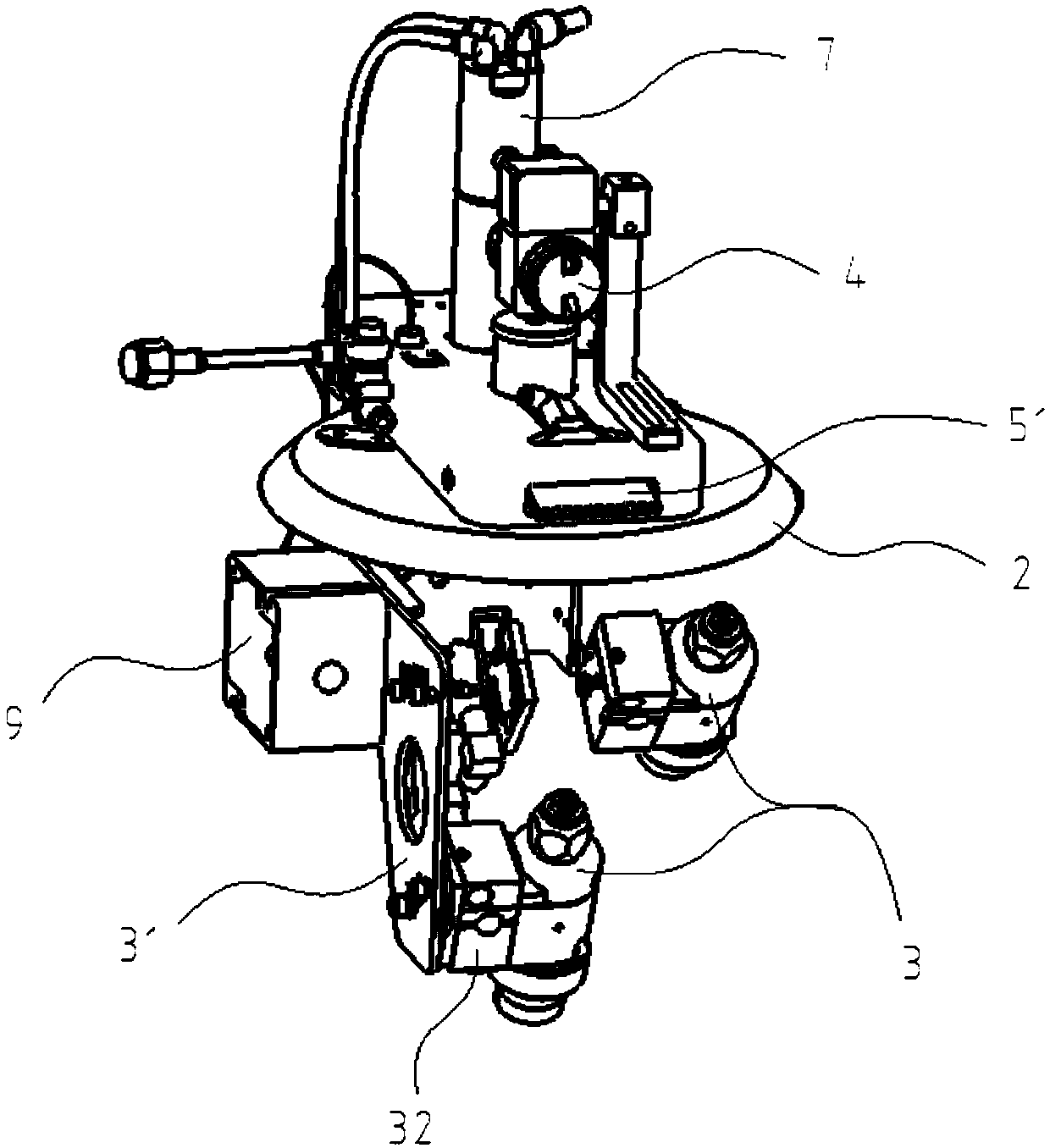

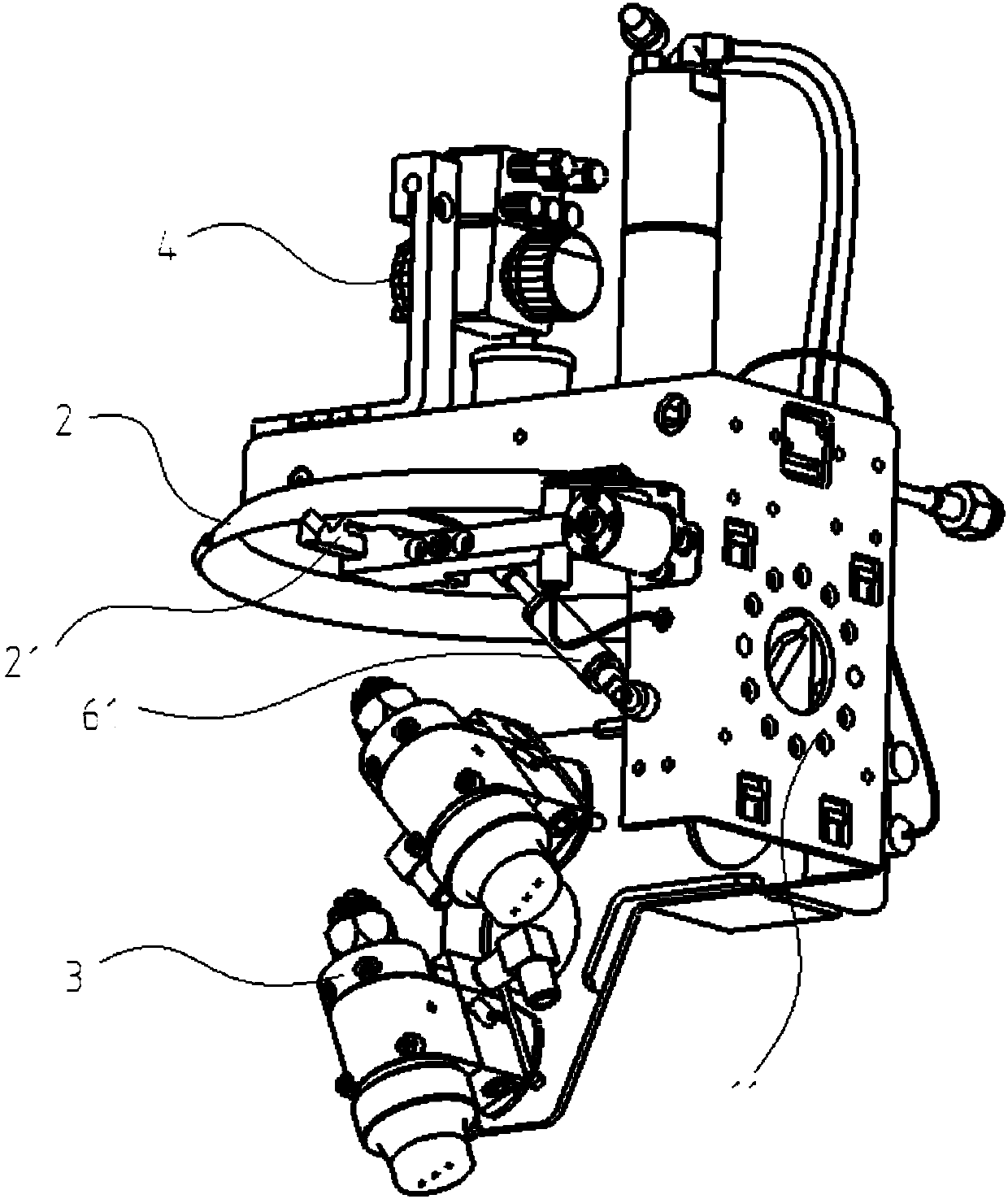

[0029] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 To attach Figure 4 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

[0030] figure 1 It is a structural diagram of an embodiment of a spraying integrated shielding device of the present invention; figure 2 It is a structural diagram of a viewing angle of a preferred embodiment of the present invention; image 3 It is a structural diagram of another perspective of a preferred embodiment of the present invention; Figure 4 It is a partial sectional view of a preferred embodiment of the present invention. Such as figure 1 , figure 2 , image 3 as well as Figure 4 As shown, the spraying integrated shielding device provided in this embodiment includes: a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com