Glue dispensing process

A glue dispensing process and glue dispensing machine technology, which is applied to coatings, devices that apply liquid to the surface, etc., can solve the problems of unqualified chip loading, different amount of glue overflowing from chips, small chip area, etc. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

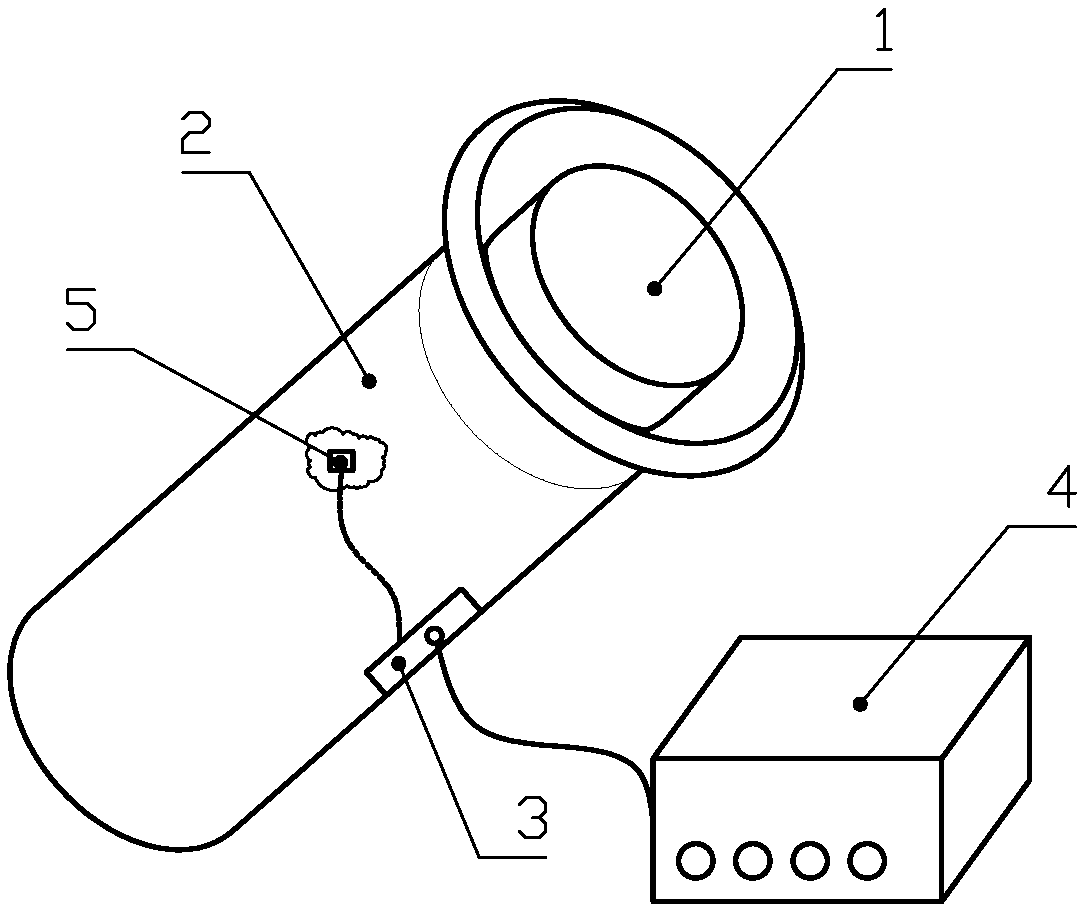

[0021] The invention mainly aims at the chip loading process in the chip packaging process, and provides a glue dispensing process, which realizes time-controlled dispensing, and the glue output is consistent; mainly by controlling the working temperature of the conductive silver paste, the viscosity of the conductive silver paste is ensured , to achieve controllable glue output, the specific steps are as follows:

[0022] Step 1. Estimate the amount of glue used for one shift of 8 hours according to the production schedule, take out an appropriate amount of conductive silver paste from the refrigerator in advance, and put it in the operating room for waking up.

[0023] In order to ensure the quality of conductive silver paste, the refrigerator storage temperature needs to be controlled at -40°C. If the amount of glue used per shift is large, it can be taken out of the refrigerator one by one in advance 1-2 hours in advance according to the actual glue usage. It is not necess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com