Two-way compact punch press

A punching machine, compact technology, used in punching machines, presses, manufacturing tools, etc., can solve the problems of uneven force transmission, limited overall structure, complex device structure, etc., to achieve compact device structure, reduce power consumption, drive The effect of power amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

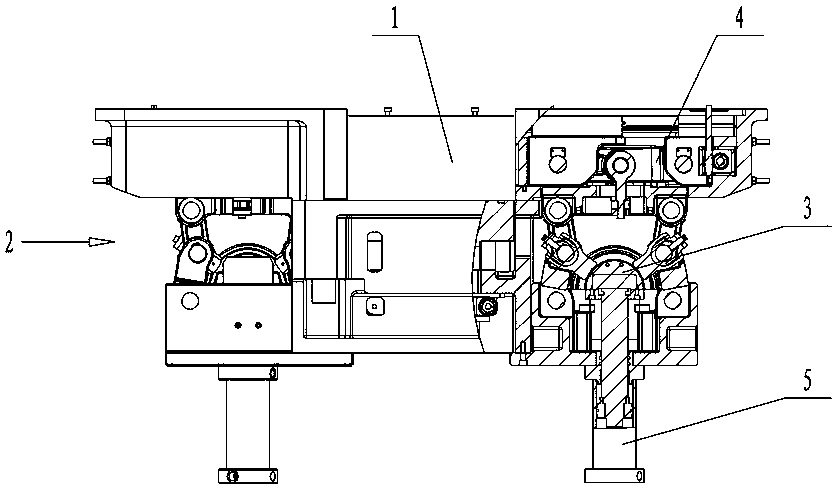

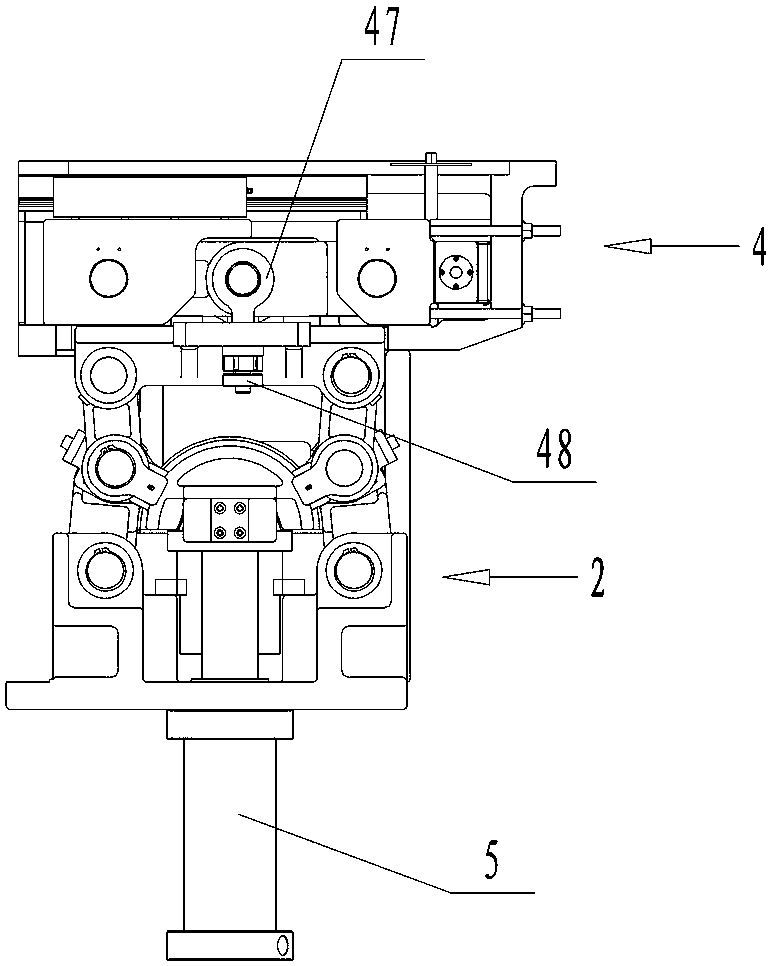

[0017] The two-way compact stamping machine of the present embodiment, as figure 1 As shown, it includes a frame 1 and two oppositely arranged side pressing devices 2 , and the side pressing device 2 includes a booster mechanism 3 and a force applying mechanism 4 .

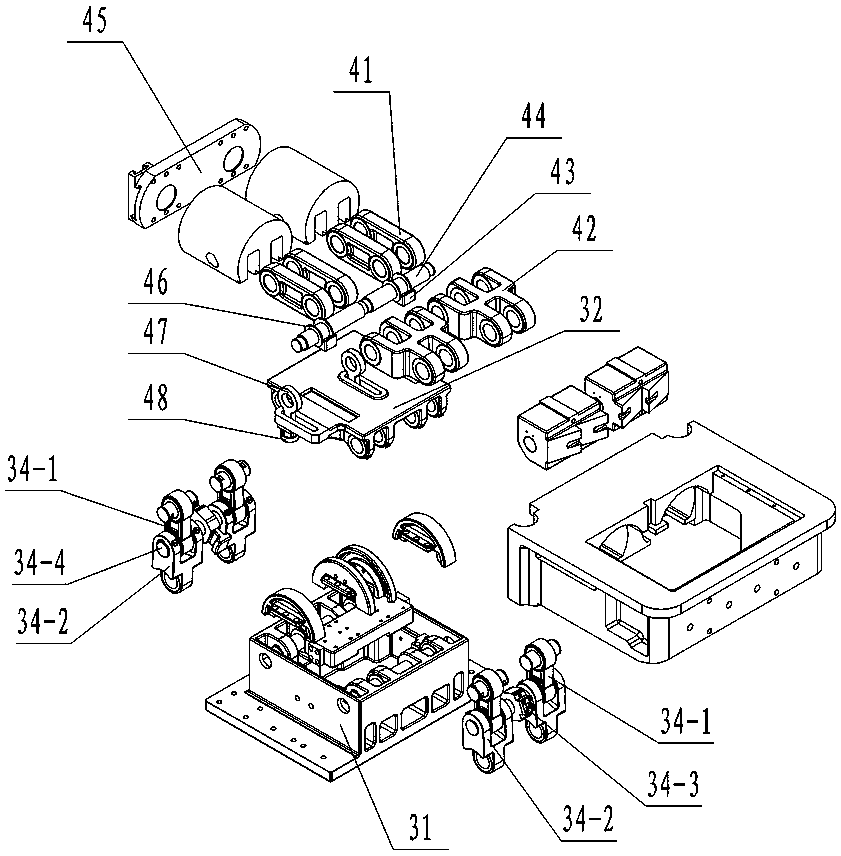

[0018] Such as Figure 2 to Figure 5 As shown, the booster mechanism 3 includes a machine base 31 fixed on the frame 1 , a platen 32 and a push rod 37 arranged on the machine base. Push rod 37 can be the push rod of oil cylinder 5 or the push rod of stepper motor, etc. the push rod of power mechanism.

[0019] A semi-cylindrical push block 33 and at least two sets of connecting rods 34 are arranged on two opposite sides of the semi-cylindrical push block between the machine base 31 and the platen 32 .

[0020] The semi-cylindrical push block 33 is fixed on the push rod 37 and can move back and forth between the machine base 31 and the platen 32. The semi-cylindrical push block 33 is formed with an arc-shaped chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com