Hemming, folding and fabric spreading cutting machine

A technology of a cloth folding machine and a sewing machine, which is applied in the direction of the cloth feeding mechanism, sewing machine components, sewing equipment, etc., can solve the problems affecting the processing efficiency and quality of the subsequent process, low efficiency, and uncontrollable sewing edge cutting precision. Excellent reliability and longevity, efficient operation, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

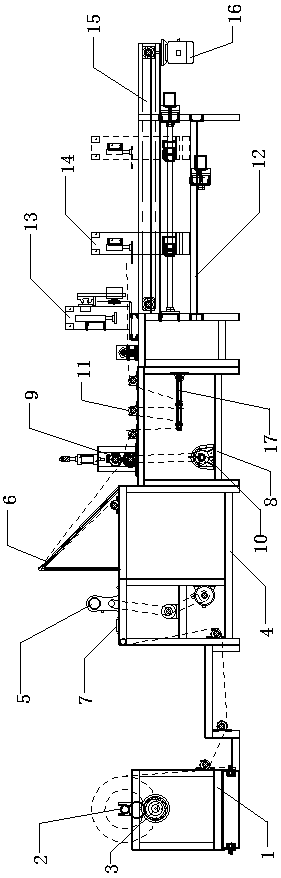

[0021] Such as figure 1 Shown is a structural schematic diagram of the present invention, the present invention is a seam folding cloth cutting machine, which sequentially includes an unwinding mechanism, a seam folding mechanism and a traction storage mechanism according to the direction of cloth travel.

[0022] The unwinding mechanism includes an unwinding frame 1, an unwinding shaft 2, an unwinding motor 3 and a magnetic powder brake; the unwinding shaft 2 is selected as an air shaft, and the unwinding shaft 2 is connected to the top of the unwinding frame 1 in rotation; the unwinding motor 3 is installed On the unwinding frame 1, its output shaft is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com