Screen printing ink for polypropylene material and preparation method of screen printing ink

A polypropylene material, screen printing technology, applied in the field of ink, can solve problems such as poor adhesion, uneven blanking density, and PP products cannot be printed, and achieve stable performance, good ink adhesion, and cost savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

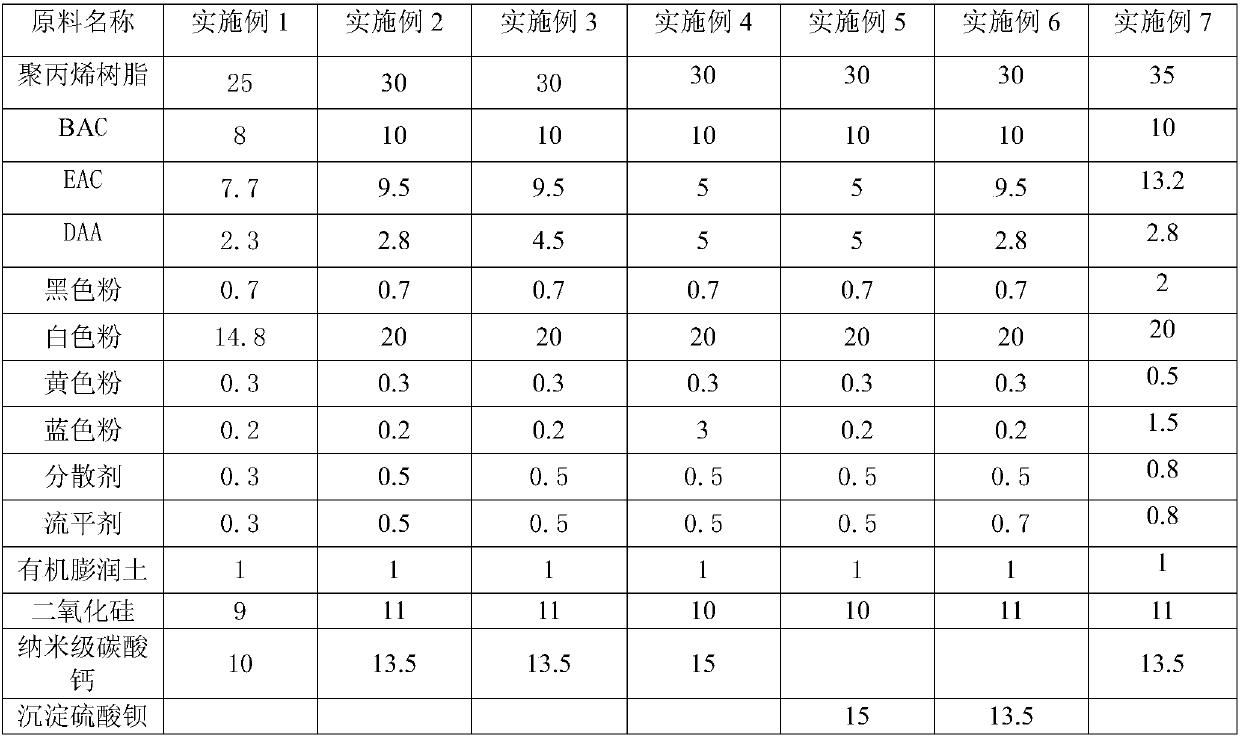

[0023] Accurately weigh each raw material component according to the following formula:

[0024] 25 parts of polypropylene resin (225 powder); 18 parts of solvent; 16 parts of pigment; 0.3 parts of dispersant; 0.3 parts of leveling agent; The pigment is composed of 0.7 parts of black powder, 14.8 parts of white powder, 0.3 parts of yellow powder and 0.2 parts of blue powder; the dispersant is BYK163, the leveling agent is BYK333, and the filler is organic bentonite (MP-100) It consists of 9 parts of silicon oxide (ST-30) and 10 parts of nano-scale calcium carbonate.

[0025] Preparation process: Put polypropylene resin into the preparation container, then put in n-butyl acetate and dispersant in turn, disperse with a disperser, slowly increase the speed to 1000r / min, disperse for 5min-10min until the above raw materials are fully mixed; Put the pigments into the above materials in turn, disperse at a speed of 1500r / min-2000r / min for 20min-30min until the dispersion is uniform...

Embodiment 2

[0027] Accurately weigh each raw material component according to the following formula:

[0028] 30 parts of polypropylene resin; 22.3 parts of solvent; 21.2 parts of pigment; 0.5 parts of dispersant; 0.5 parts of leveling agent; 0.7 parts of powder, 20 parts of white powder, 0.3 parts of yellow powder and 0.2 parts of blue powder; the dispersant is BYK163, the leveling agent is BYK333, and the filler consists of 1 part of organic bentonite, 11 parts of silicon dioxide and nano-scale calcium carbonate 13.5 parts composition.

[0029] Refer to Example 1 for the preparation process.

Embodiment 3

[0031] Accurately weigh each raw material component according to the following formula:

[0032] 30 parts of polypropylene resin; 24 parts of solvent; 21.2 parts of pigment; 0.5 parts of dispersant; 0.5 parts of leveling agent; 0.7 parts of powder, 20 parts of white powder, 0.3 parts of yellow powder and 0.2 parts of blue powder; the dispersant is BYK163, the leveling agent is BYK333, and the filler consists of 1 part of organic bentonite, 11 parts of silicon dioxide and nano-scale calcium carbonate 13.5 parts composition.

[0033] Refer to Example 1 for the preparation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com