Rock-fill concrete core wall cemented rock-fill dam and construction method thereof

A technology of rock-fill concrete and construction methods, which is applied in the direction of infrastructure engineering, dams, barrages, etc., can solve the problems of increasing project investment, flooding and collapse of rock-fill dams, etc., and achieves good anti-seepage effect, small non-uniform settlement, The effect of reducing the amount of cement per unit volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

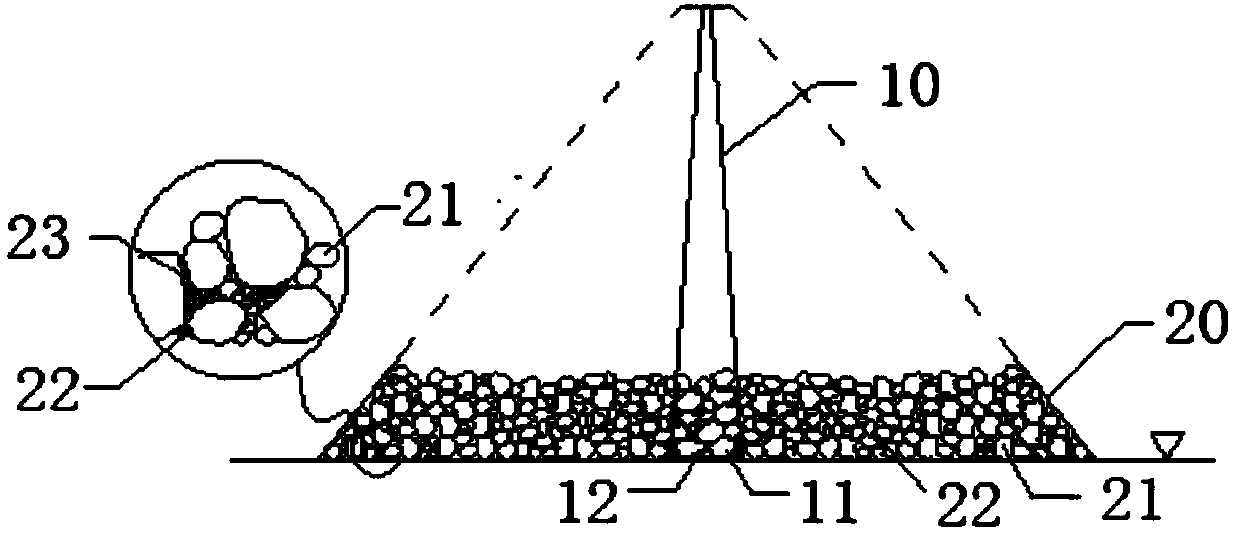

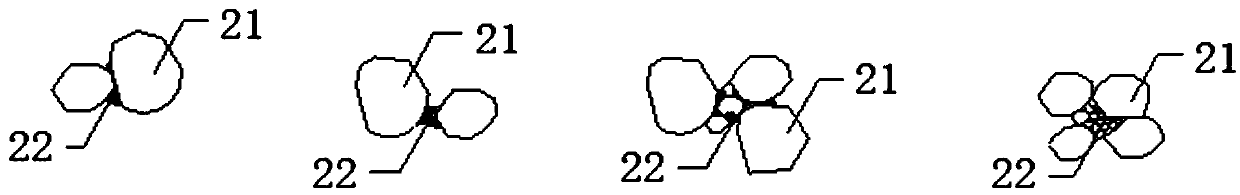

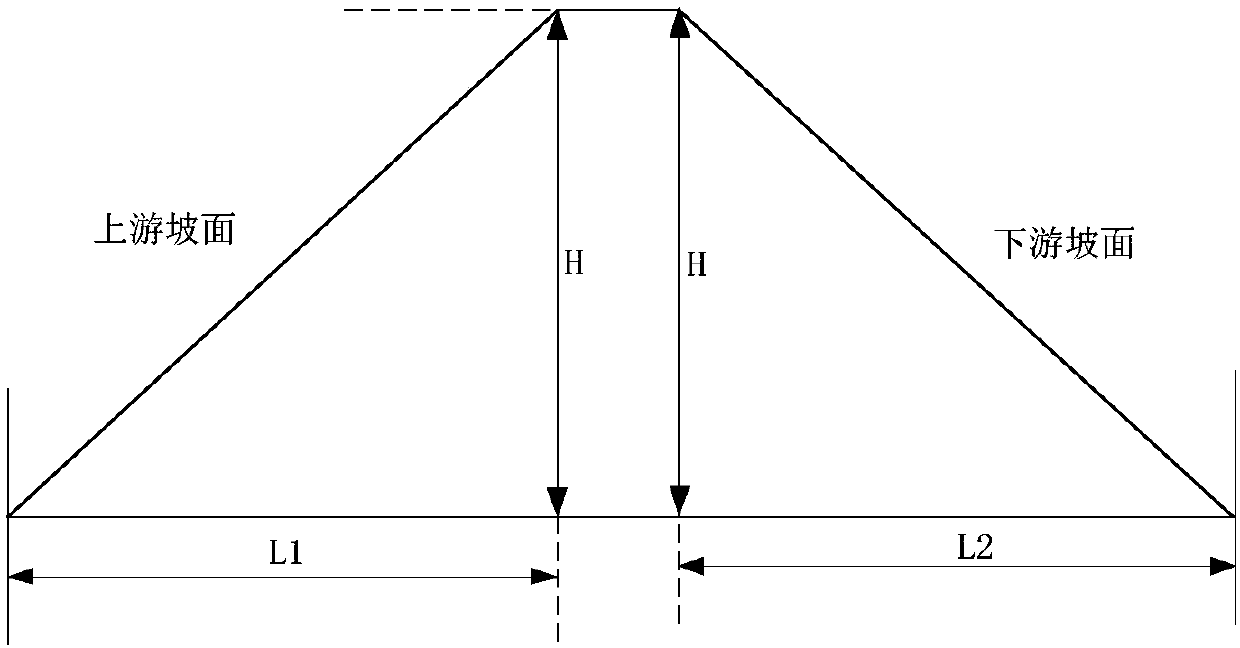

[0034] According to one aspect of the present invention, the present invention proposes a cemented rockfill dam with a rock-fill concrete core, such as figure 1As shown, it includes: a rock-fill concrete core wall 10 and a cemented rock-fill concrete core wall 20, the rock-fill concrete core wall 10 is located at the center, and the cemented rock-fill material dam body 20 is formed on both sides of the rock-fill concrete core wall 20, wherein the rock-fill concrete The concrete core wall 10 includes: block stone 11, the first sel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap