Pre-stress applying device for steel pipe inner support of deep foundation pit

A technology of applying devices and prestressing, applied in infrastructure engineering, excavation, construction, etc., can solve the problems of large material consumption, non-adjustable, cumbersome process, etc., and achieve the effect of less material consumption, easy dismantling, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with embodiment.

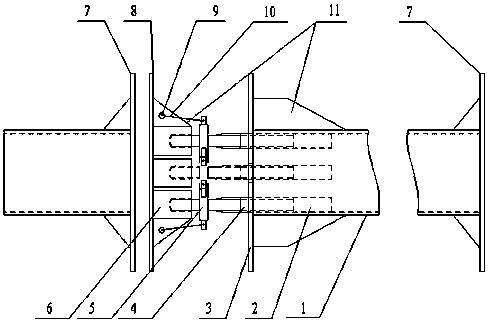

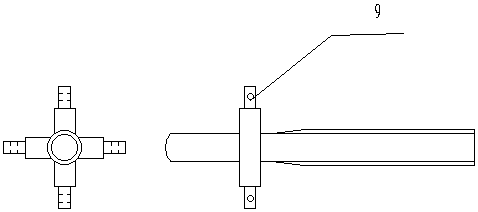

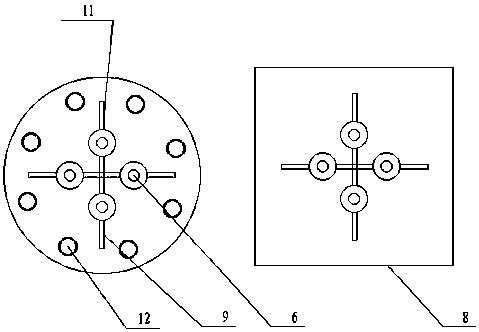

[0017] A deep foundation pit steel pipe internal support prestressing device of the present invention is characterized in that the device includes a steel pipe 1, a sleeve 2, an annular steel plate 3, a bolt 4, a flange 7, and a steel trim plate 8, and the steel pipe 1 The inner ring of one end is welded to the sleeve 2, and the other end is connected to the flange 7; the annular steel plate 3 is welded to the steel pipe 1 and the sleeve 2; the annular steel plate 3 is welded to the outer wall of the steel pipe 1 with ribs 11; U-shaped sleeve 6 is welded on 8; ribs 11 are welded on the outer wall of the steel plate 8 and U-shaped sleeve 6; the ribs 11 are drilled with fixing holes 9; The bolts 4 are connected; the bolts 4 are welded with a cross nut 5; the cross nut 5 is drilled with a fixing hole 9; the fixing hole 9 is connected through a steel wire rope 10.

[0018] The steel tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com