Roof-contacted filling monitoring system

A monitoring system and monitoring sensor technology, applied in fillings, mining equipment, earthwork drilling, etc., can solve the problems of inconvenient installation and use, and achieve the effect of easy installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

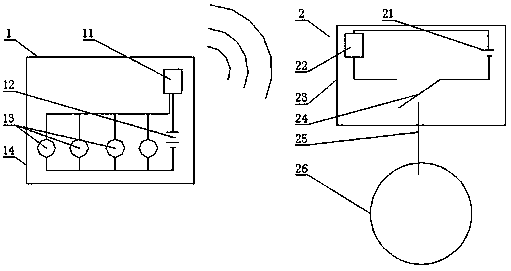

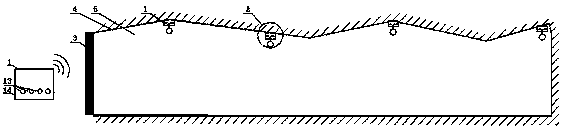

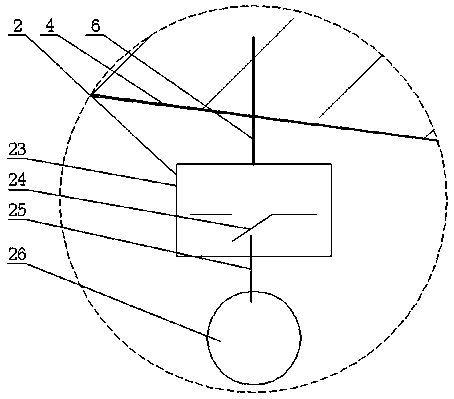

[0024] refer to Figure 1~3 , a filling and topping monitoring system of this embodiment, comprising four topping detection sensors 1 and a topping monitoring display host 2, said topping monitoring sensors including a float 26, a pressure touch switch 24 and a wireless signal transmitter 22. The floating ball 26 is connected to the pressure touch switch 24 through the actuator rod 25, and the wireless signal transmitter 22 is electrically connected to the power supply 12 through the pressure touch switch 24; device 11 and several light-emitting diodes 13, the light-emitting diodes 13 are connected in parallel, and connected to the main power supply 21 through the wireless signal receiver 11, the wireless signal receiver 11 receives the signal sent by the top detection sensor 1, and controls the corresponding The working state of the light emitting diode 13.

[0025] The roof contact monitoring sensor is fixed on the roof 4 of the filling roadway through expansion bolts 6 or ...

Embodiment 2

[0031] refer to Figure 4 , a filling and top-connecting monitoring system of this embodiment, compared with Embodiment 1, there are the following differences:

[0032] A filling top contact monitoring system includes six top contact detection sensors 1 and a top contact monitoring display host 2 .

[0033] The roof connection detection display host also includes an alarm device, and the alarm device includes several alarm devices 15 corresponding to the roof connection detection sensor 1 .

[0034] The roof contact monitoring sensor is fixed on the roof 4 of the filling roadway by adhesive.

[0035] The working principle and usage method of a filling and roofing monitoring system of the present invention are as follows:

[0036] The top connection monitoring sensor is installed on the top plate 4 of the filling roadway. When filling and top connection, the floating ball 26 will float up and trigger the pressure touch switch 24, and then send a signal to the top connection d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com