Rocker arm mechanism

A technology of rocker mechanism and inner rocker arm, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve problems such as complex process, poor sealing performance, and difficult design of moving oil circuit, so as to achieve simple oil circuit layout and improve sealing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

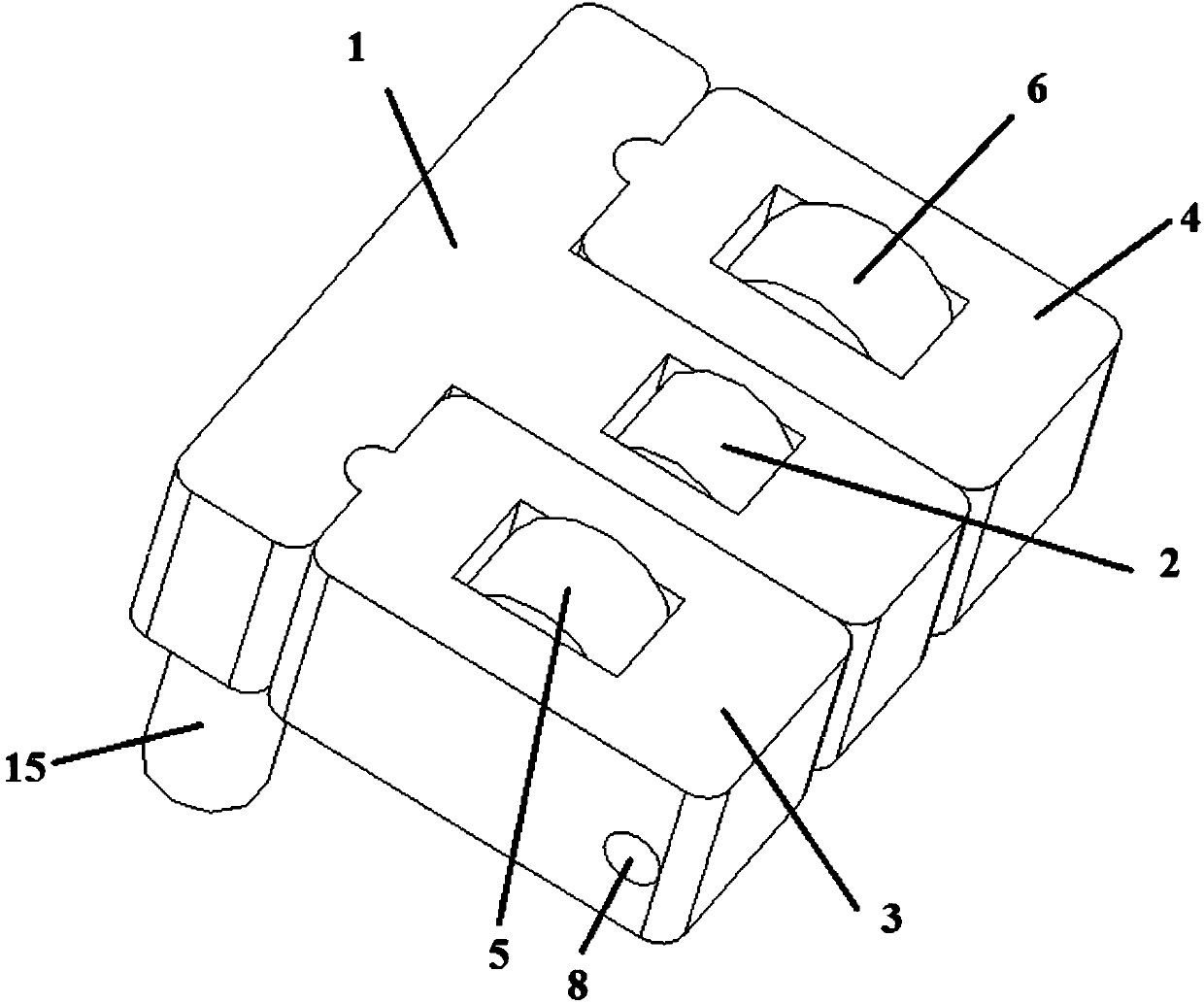

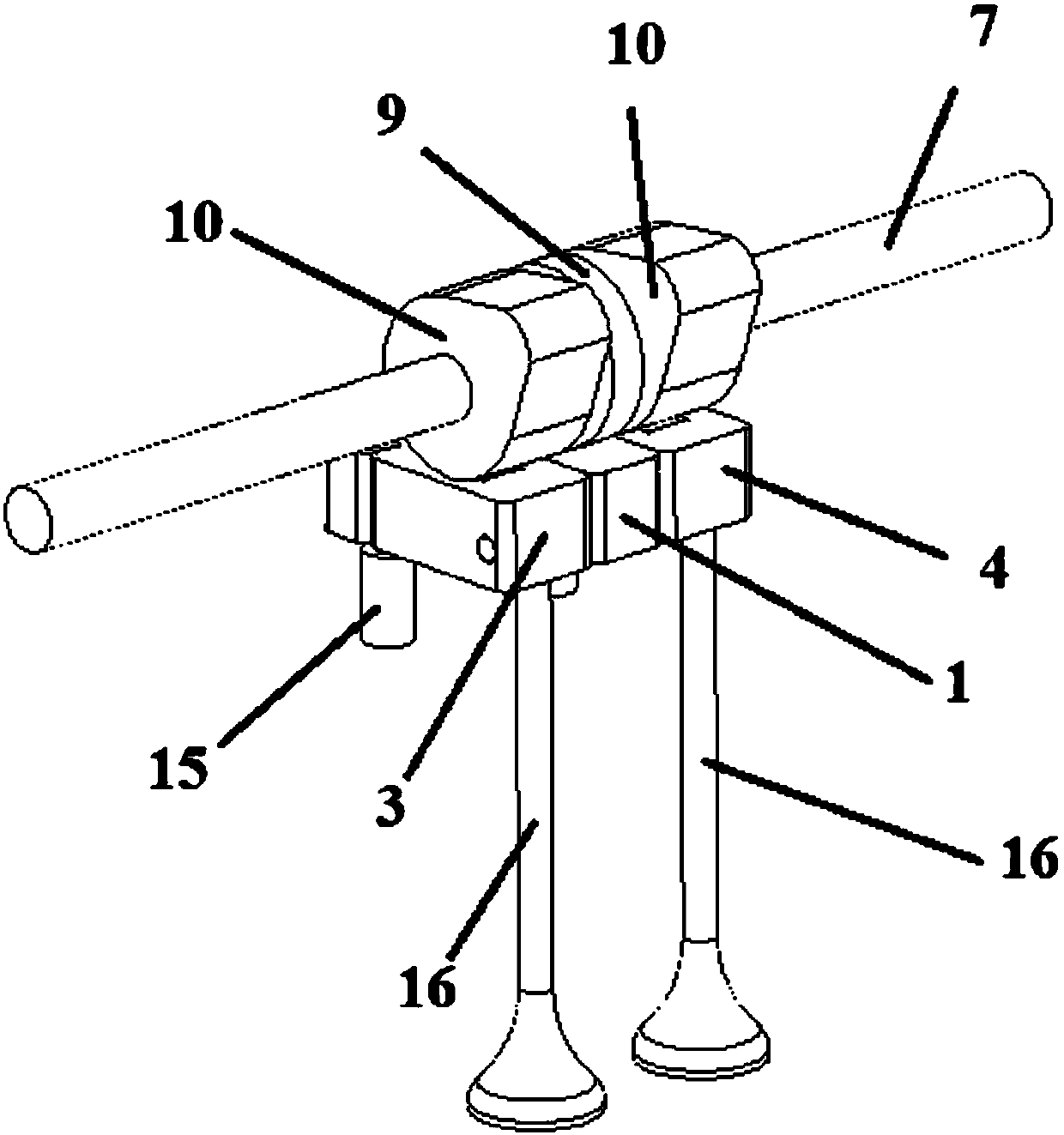

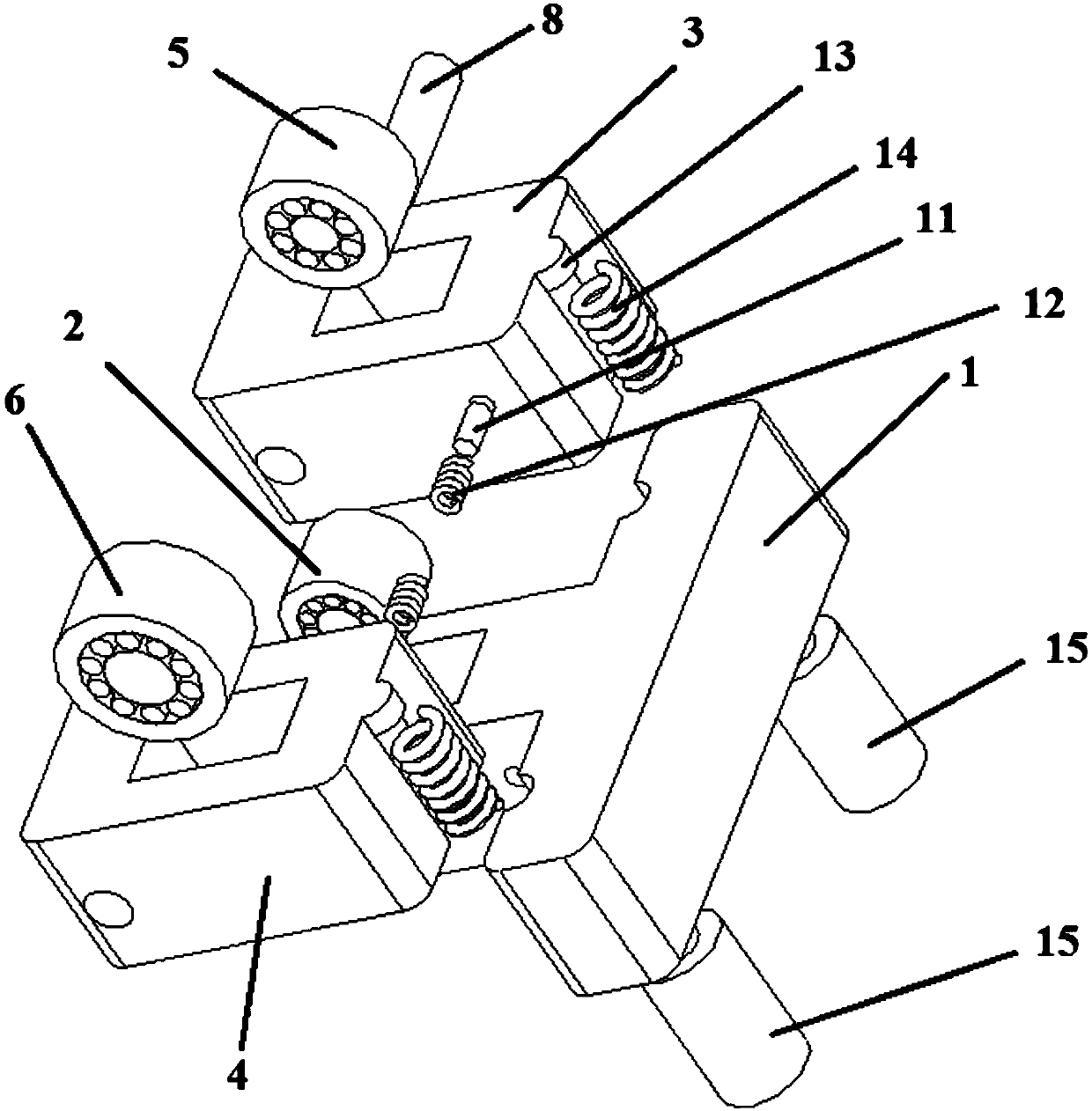

[0019] Such as Figures 1 to 4 As shown, the present invention provides a rocker mechanism, which includes: an inner rocker arm and an outer rocker arm 1 that are rotatably connected via a connecting shaft 8, and a camshaft 7 located on the upper part of the inner rocker arm and the outer rocker arm 1 , wherein: the outer rocker arm 1 is T-shaped and is rotatably connected with a base circle needle bearing 2 in the mounting hole in the body of the trailing arm; the inner rocker arm is rectangular and is located at the center of the outer rocker arm 1 The left and right outer sides of the trailing arm include: a low-lift inner rocker arm 3 and a high-lift inner rocker arm 4, and a low-lift needle roller bearing is arranged in a rotational connection in the installation hole in the body of the low-lift inner rocker arm 3 5. In the mounting hole of the body of the high-lift inner rocker arm 4, a high-lift needle roller bearing 6 is rotatably arranged; and the cam part on the cams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com