Warming furnace

A heating furnace and flue pipe technology, which is applied in the field of heating furnaces, can solve the problems of low heat exchange efficiency of biomass heating furnaces, and achieve the effects of improving heat release efficiency, smoothness, and release efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

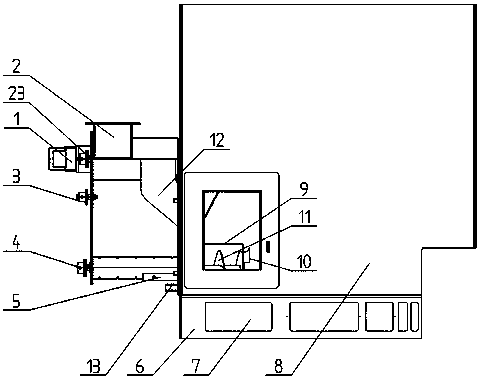

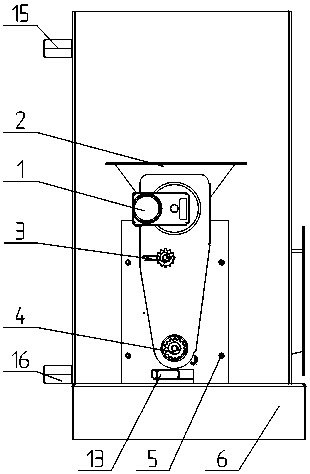

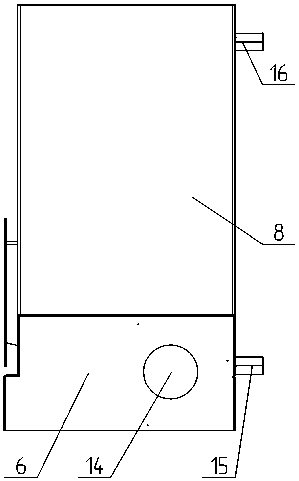

[0028] Embodiment 1: A heating furnace, including a feeding mechanism, a combustion mechanism and a smoke pipe 19, the feeding mechanism at least includes a feeding port 2, the feeding port 2 is connected to a feeding pipeline 12, and the end of the feeding pipeline 12 is connected to a combustion mechanism The combustion mechanism includes a combustion chamber 9, an air inlet pipe 13 is installed at the bottom of one side of the combustion chamber 9, a smoke pipe 19 is distributed above the combustion chamber 9, and an ash box 6 is below the combustion chamber 9; the combustion chamber The outside of 9 is covered with water tank 8.

Embodiment 2

[0029] Embodiment 2: a heating furnace, including a feeding mechanism, a combustion mechanism and a smoke pipe 19, the feeding mechanism at least includes a feeding port 2, the feeding port 2 is connected to a feeding pipeline 12, and the end of the feeding pipeline 12 is connected to a combustion mechanism The combustion mechanism includes a combustion chamber 9, an air inlet pipe 13 is installed at the bottom of one side of the combustion chamber 9, a smoke pipe 19 is distributed above the combustion chamber 9, and an ash box 6 is below the combustion chamber 9 and the smoke pipe 19; The outside of the combustion chamber 9 and the smoke pipe 19 is covered with a water tank 8 .

Embodiment 3

[0030] Embodiment 3: A heating furnace, wherein the feeding device further includes a screw feeding mechanism 17, the screw feeding mechanism 17 is located at the connection between the feeding port 2 and the feeding pipeline 12, and the screw feeding mechanism 17 is powered by the driving device 1. The feeding pipe 12 is composed of two pipes with a rectangular cross section, and the connection position of the two pipes with a rectangular cross section is a smooth transition. A screw propeller 10 is also installed in the combustion chamber 9, and the screw propeller 10 is connected with a power device or a transmission device through a transmission shaft. The screw pusher 10 is connected with the power gear 23 on the driving device 1 by a chain through the transmission gear 4 at the end of the transmission shaft. A tightening gear 3 is also installed between the transmission gear 4 and the power gear 23 . The structures and connections of the remaining parts are the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com