Near-infrared multispectral sorting equipment

A near-infrared, multi-spectral technology, applied in the field of sorting, can solve the problems of low scanning line frequency, no high-speed near-infrared device that can realize large-volume online sorting, and difficult to achieve, and achieve the effect of improving the recognition rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

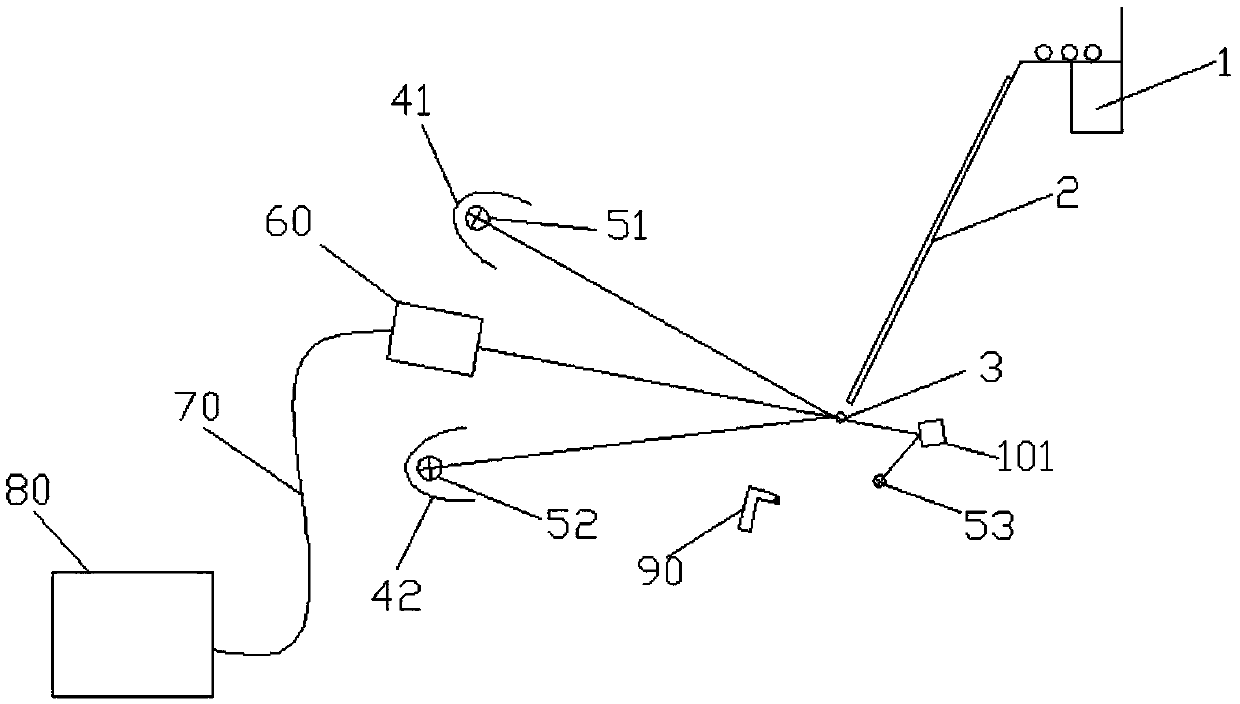

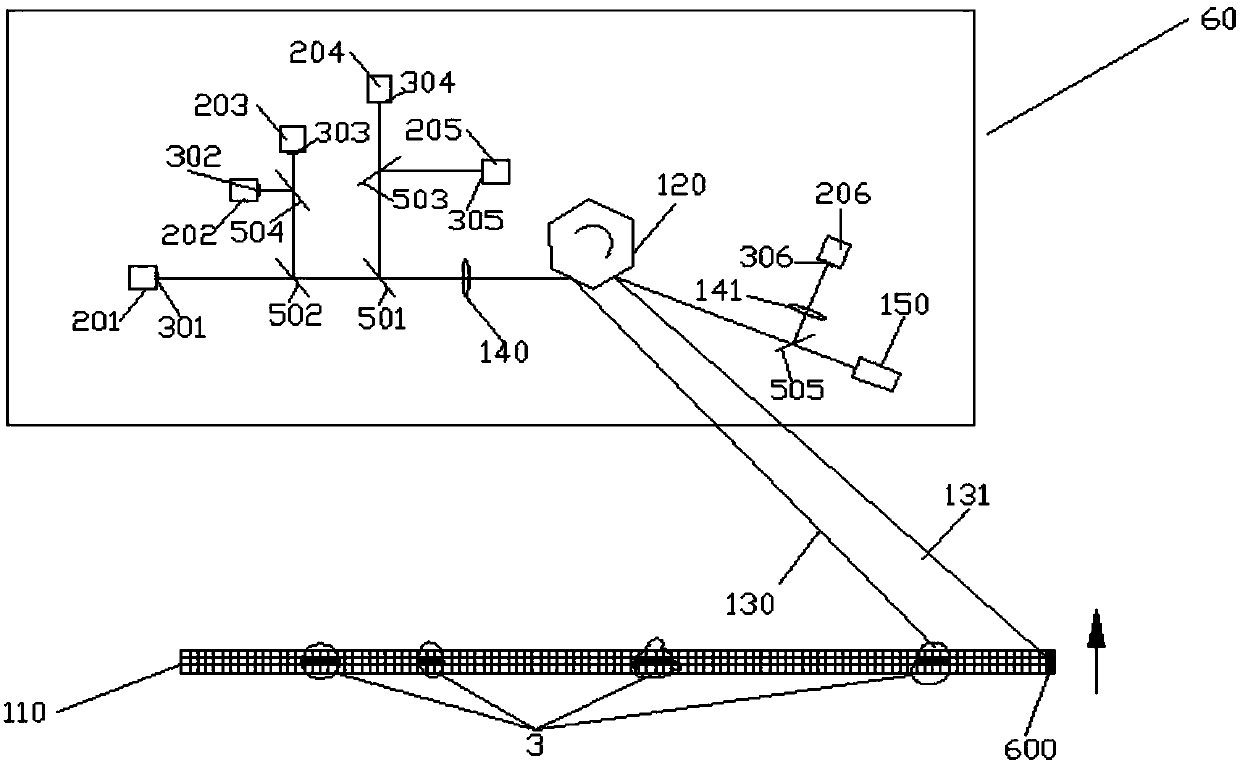

[0044] figure 1 A schematic diagram of a near-infrared multispectral sorting device provided by this patent is shown. The near-infrared multi-spectral sorting equipment mainly includes light sources 51-52, light-collecting devices 41-42, a vibrator 1, a material chute 2, an optical signal receiving device 60, a background light source 53, a background plate 101, a spray valve device 90 and Image processing display device 80 . The vibrator 1 guides the material along the material chute 2 , irradiates the measured material 3 through the near-infrared light source 51 - 52 , and receives the light wave signal reflected by the measured material 3 through the optical signal receiving device 60 . The light sources 51-52 are near-infrared light sources. The light-gathering devices 41-42 adopt spotlight shades.

[0045] According to different structural requirements, different near-infrared light sources can be selected, such as figure 1 The light sources 51-53 used in the method c...

Embodiment 2

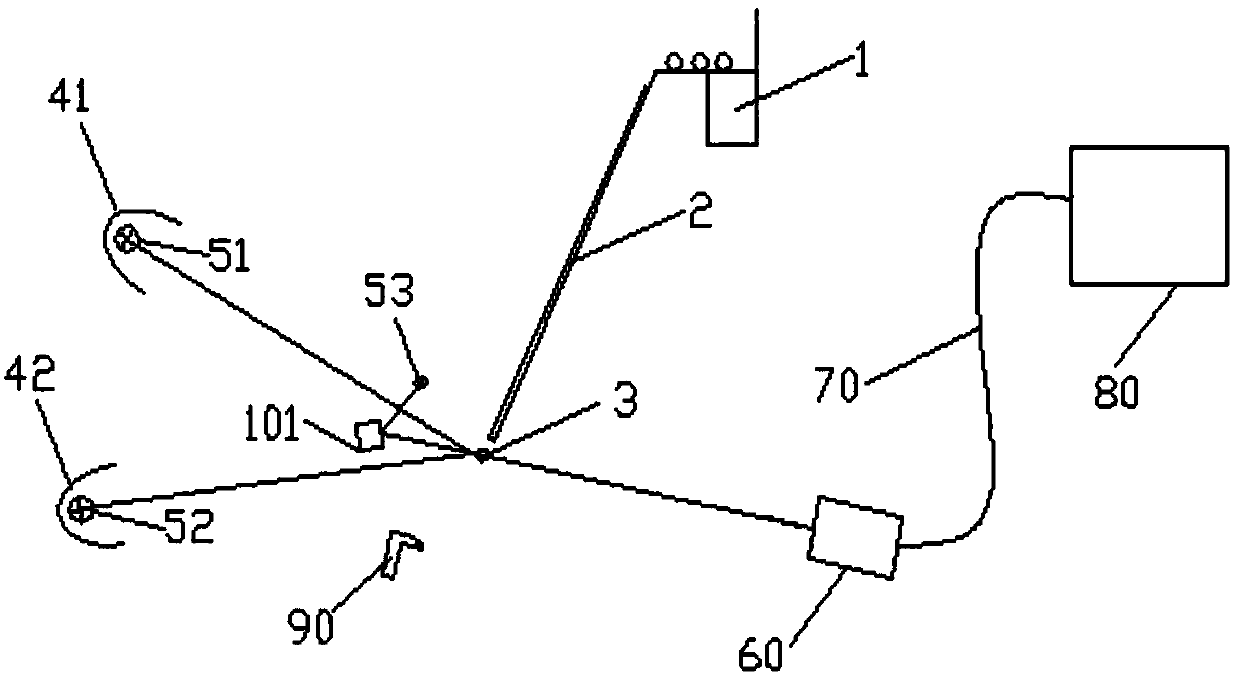

[0058] This patent application can also be according to the structural schematic diagram of another embodiment, such as image 3 A near-infrared multi-spectral sorting device with another structure is designed as shown. The difference between it and the above-mentioned first embodiment is that the direction of the optical signal receiving device 60 and the light sources 51-52 relative to the material is different, and the background light source 53 and the background plate 101 are on the same side as the light sources 51-52. In this embodiment, the light sources 51-52 After the near-infrared light emitted by 52 is irradiated on the material 3, it is reflected, absorbed, and transmitted by the material 3, and the transmitted light will be received by the optical signal receiving device 60, and the optical signal will be converted into multiples according to the method described in the first embodiment. Electrical signals in spectral bands.

Embodiment 3

[0060] This patent application can also be according to the structural schematic diagram of the third embodiment, such as Figure 4 A near-infrared multi-spectral sorting device with another structure is designed as shown. The difference from the first embodiment above is that light sources 51-54 and optical signal receiving devices 61, 62 are arranged on both sides of the material, and background light sources 55, 56 and background plates 101, 102 are arranged on both sides of the material. , in this embodiment, after the near-infrared rays emitted by the light sources 51-54 are irradiated on the material 3, they are reflected, absorbed, and transmitted by the material 3, and the rays transmitted by 51-52 and the rays reflected by 53-54 will be received by the optical signal Received by the device 62, the optical signal is converted into an electrical signal with multiple spectral bands according to the method described in the first embodiment. Similarly, the light transmitte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandwidth | aaaaa | aaaaa |

| Bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com