Optical efficiency measurement device and test method of trough solar collector tube

A trough solar energy and optical efficiency technology, applied in the field of solar thermal utilization, can solve the problems of uneven fluid distribution, large test error, large air change, etc., to reduce the risk of wear or damage, improve uniformity and stability, Reduce the effect of temperature unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

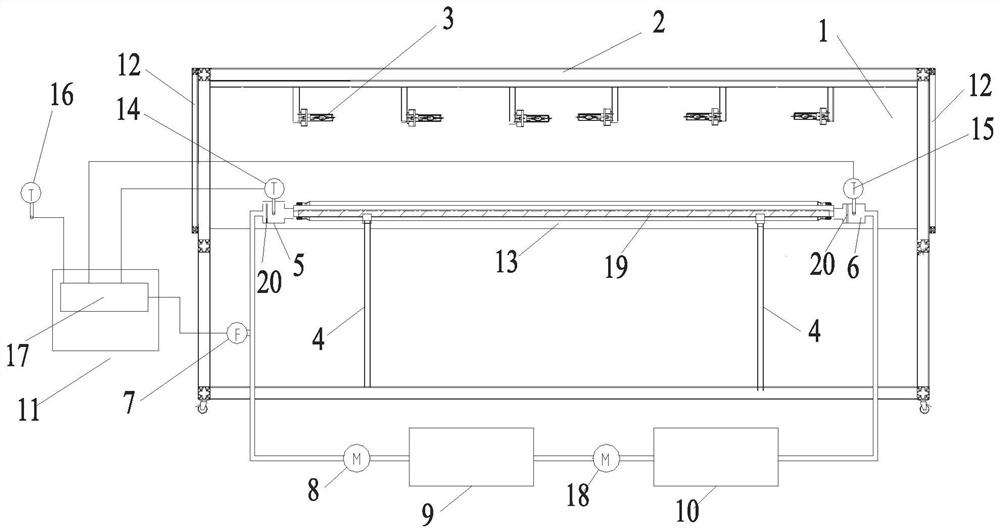

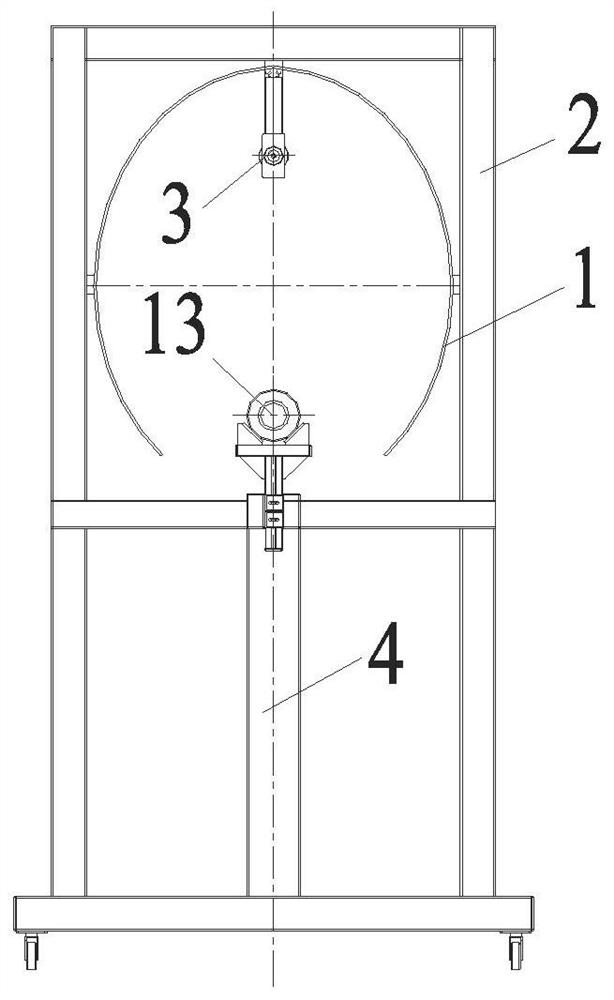

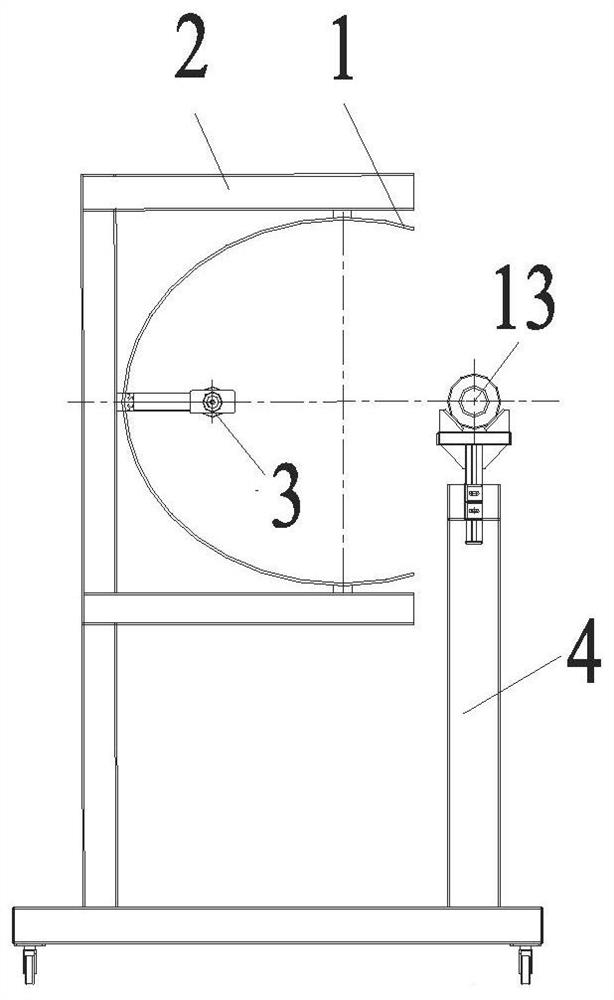

[0038] Such as figure 1 with figure 2 As shown, the vertical trough solar collector tube optical efficiency measuring device of the present invention comprises an elliptical concentrator 1, an elliptical concentrator support 2, a sun simulation light source 3, a trough solar thermal collector support 4, a first uniform temperature Device 5 , second temperature equalizing device 6 , flow meter 7 , first fluid-driven pump 8 , liquid supply tank 9 , liquid storage tank 10 and measurement system 11 . The sun simulation light source 3 and the trough-type solar collector tube 13 to be tested are respectively located on the two focal lines of the elliptical concentrator 1, and the two ends of the elliptical concentrator 1 are end caps 12 with reflective mirror surfaces, and the elliptical concentrator The inner wall of the device 1 has a mirror sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com