Manufacturing method of intelligent electric quantity transmitter

The technology of a power transmitter and its manufacturing method is applied in the direction of measuring electrical variables, manufacturing measuring instruments, instruments, etc., and can solve the problems of no manufacturing method and cumbersome production of power transmitters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

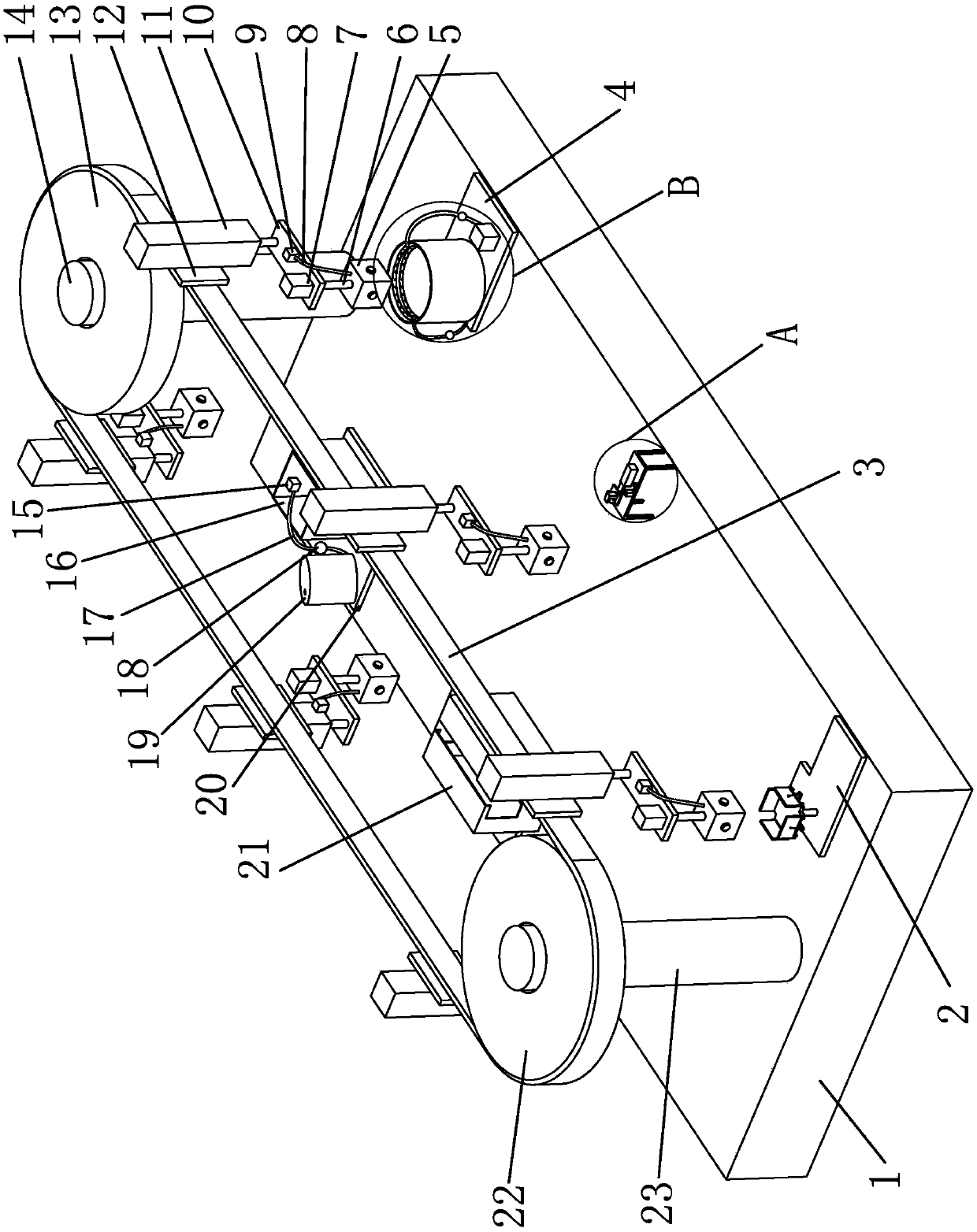

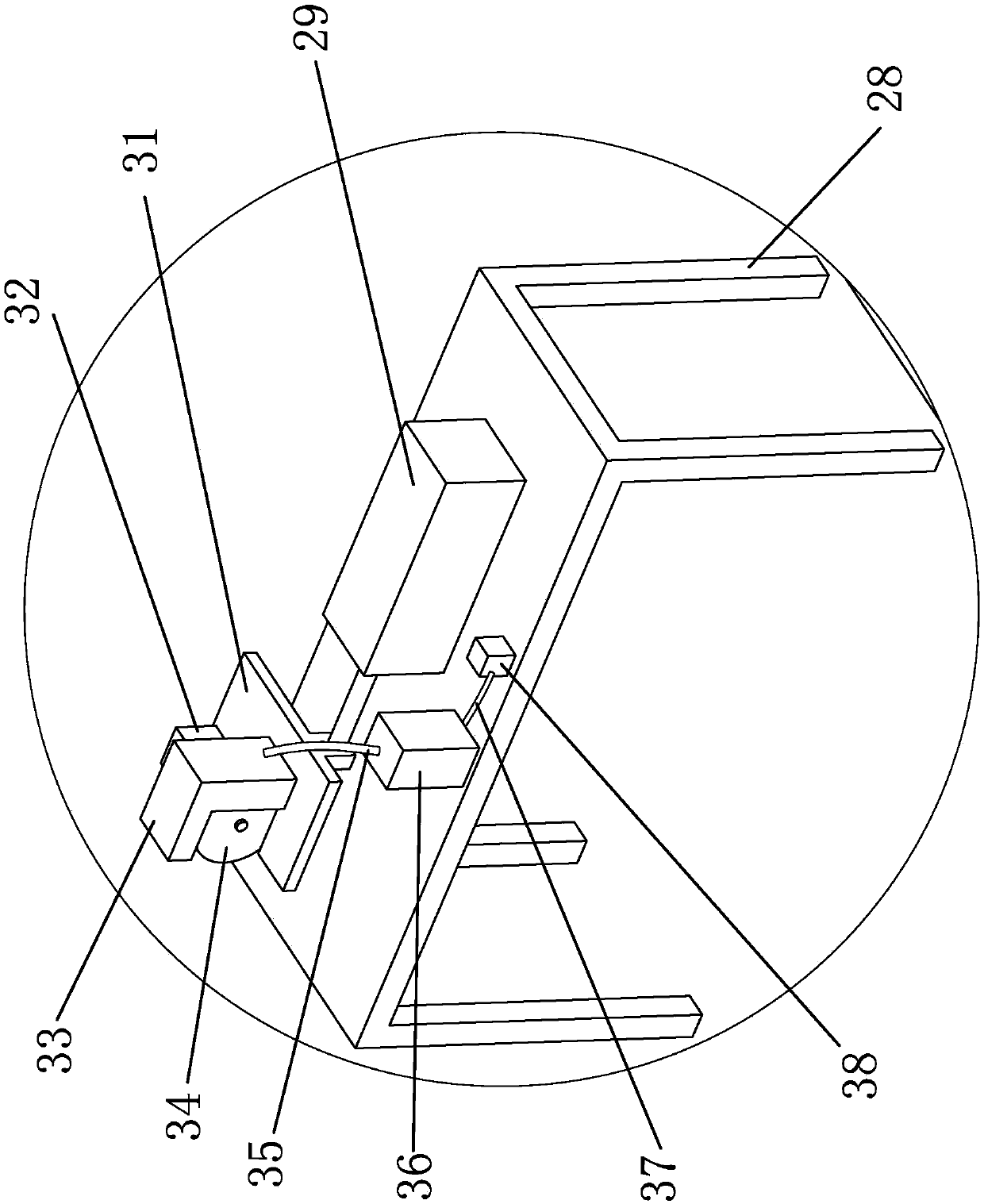

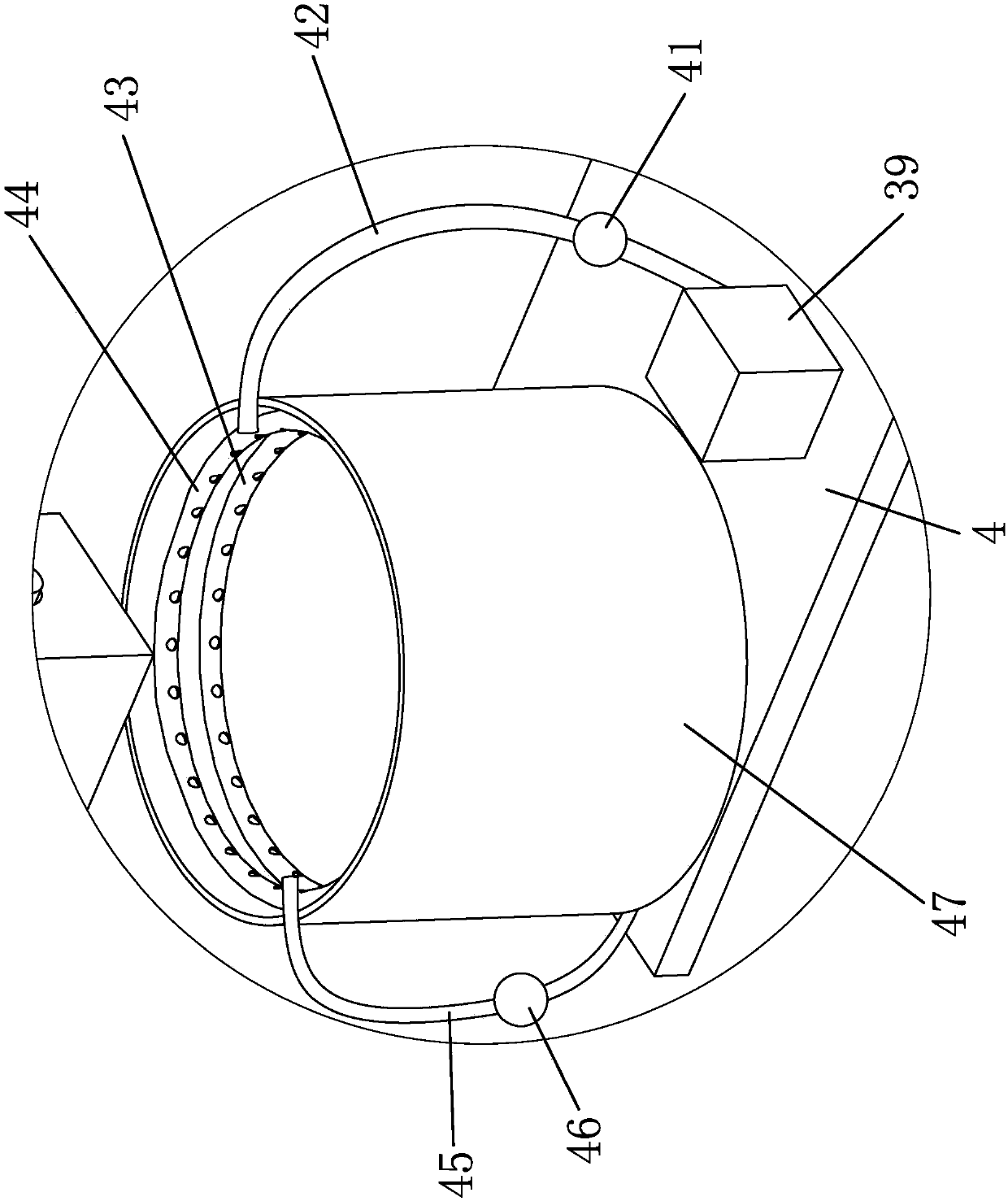

[0051] The manufacturing method of the smart power transmitter includes a housing, an upper cover, a fence-type terminal block, a fixing frame, a sponge pad, insulating paper, a circuit board 1 and a circuit board 2. In this embodiment, The upper cover, fence-type terminal block, fixing frame, sponge pad, and insulating paper all adopt existing products available on the market. The first circuit board is a PT / CT mounting board available on the market, and the second circuit board is a commercially available Available power supply and output boards; including the following steps: a. Process the sheet material into a shell through the production system, with a coating on the outside of the shell, the thickness of the coating is 0.5-1.5mm, and the thickness of the coating is 0.7mm; The sheet material in step a includes four side plates and a bottom plate; b. Assembling the fence-type terminal block on the outer end face of the upper cover, and assembling the barrier-type terminal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com