Seeding leakage detection-reseeding system and potato seeding leakage detection-reseeding integrated control system and method

A control system and potato technology, applied in potato planters, general control systems, planting methods, etc., can solve problems such as missed seeding detection, difficulty in replanting, etc., to ensure reliability, improve leak detection accuracy, and have strong stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

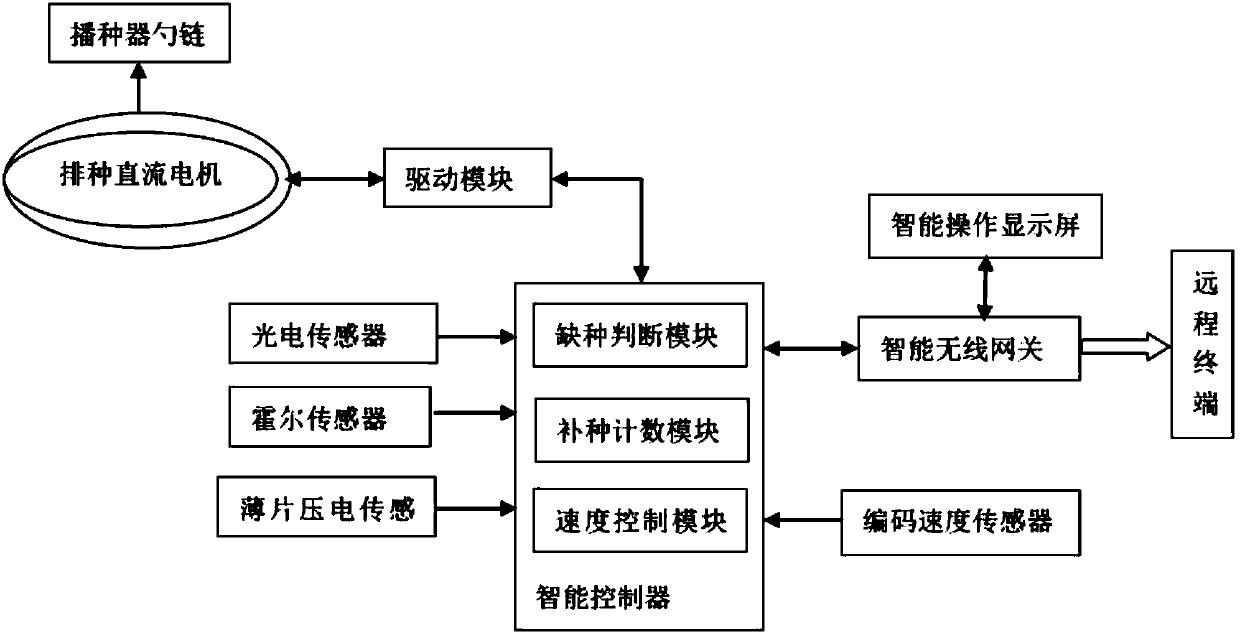

[0039] Embodiment 1. This embodiment proposes a missing-seeding detection-reseeding system, which is suitable for sowing large-sized crops such as peanuts and potatoes, and is suitable for the improvement and utilization of spoon chain or disc seeders. refer to figure 1 , which is a block diagram of the system, including the intelligent controller and the missed-seeding detection sensor connected to it, the Hall sensor, the encoding speed sensor and the seeding DC motor. Accurate detection of the position, the coded speed sensor is installed above the coaxial gear with the bottom wheel (the distance between the two is 3mm-5mm) to form the key component of stroke perception, which is used to detect the speed of the traction bottom wheel. The controllers are connected to each other to drive the scoop chain of the seeder to run independently, and directly drive the scoop chain to rotate through the seeding DC motor to realize the intelligent control of uniform distribution of pla...

Embodiment 2

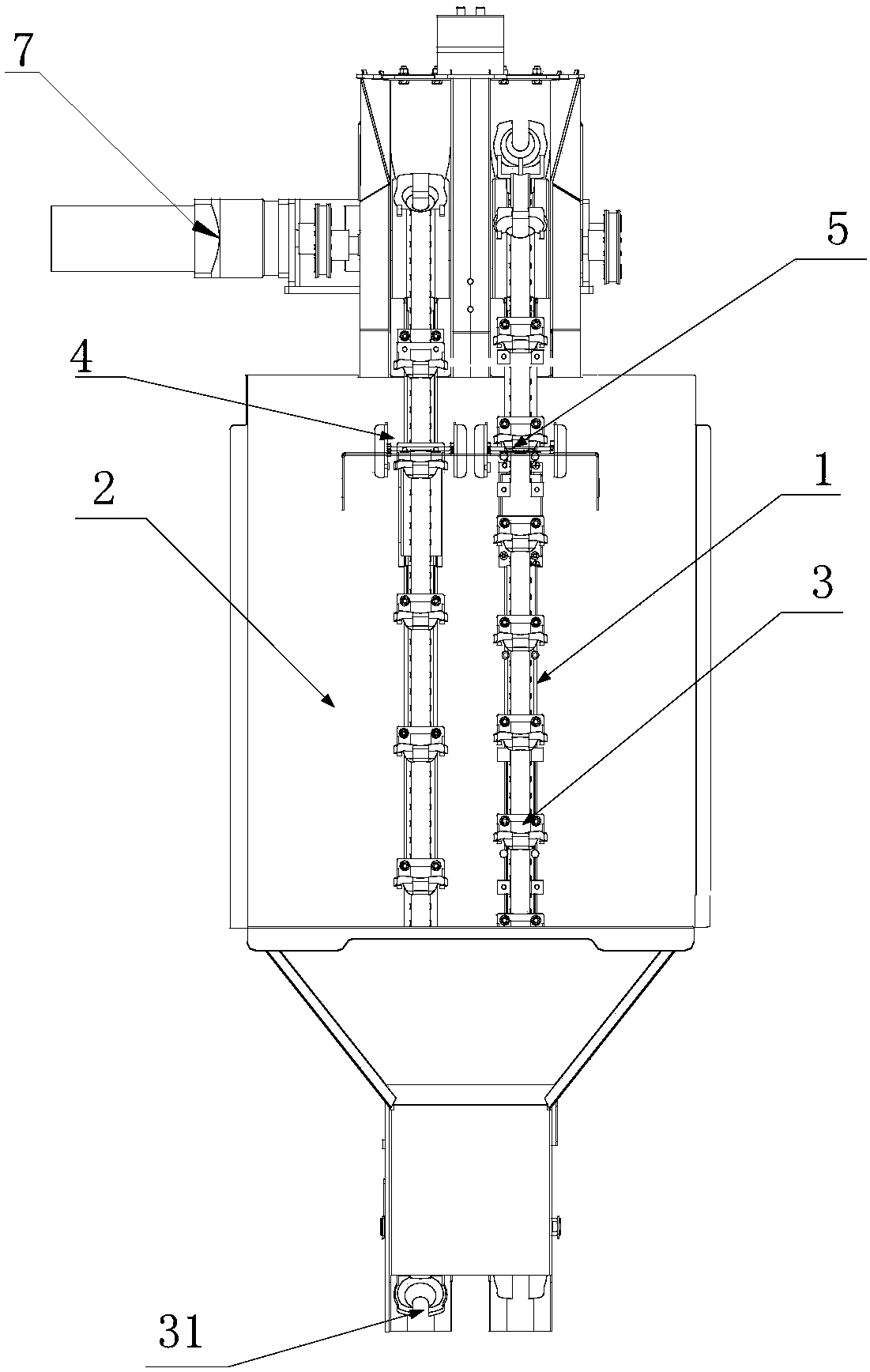

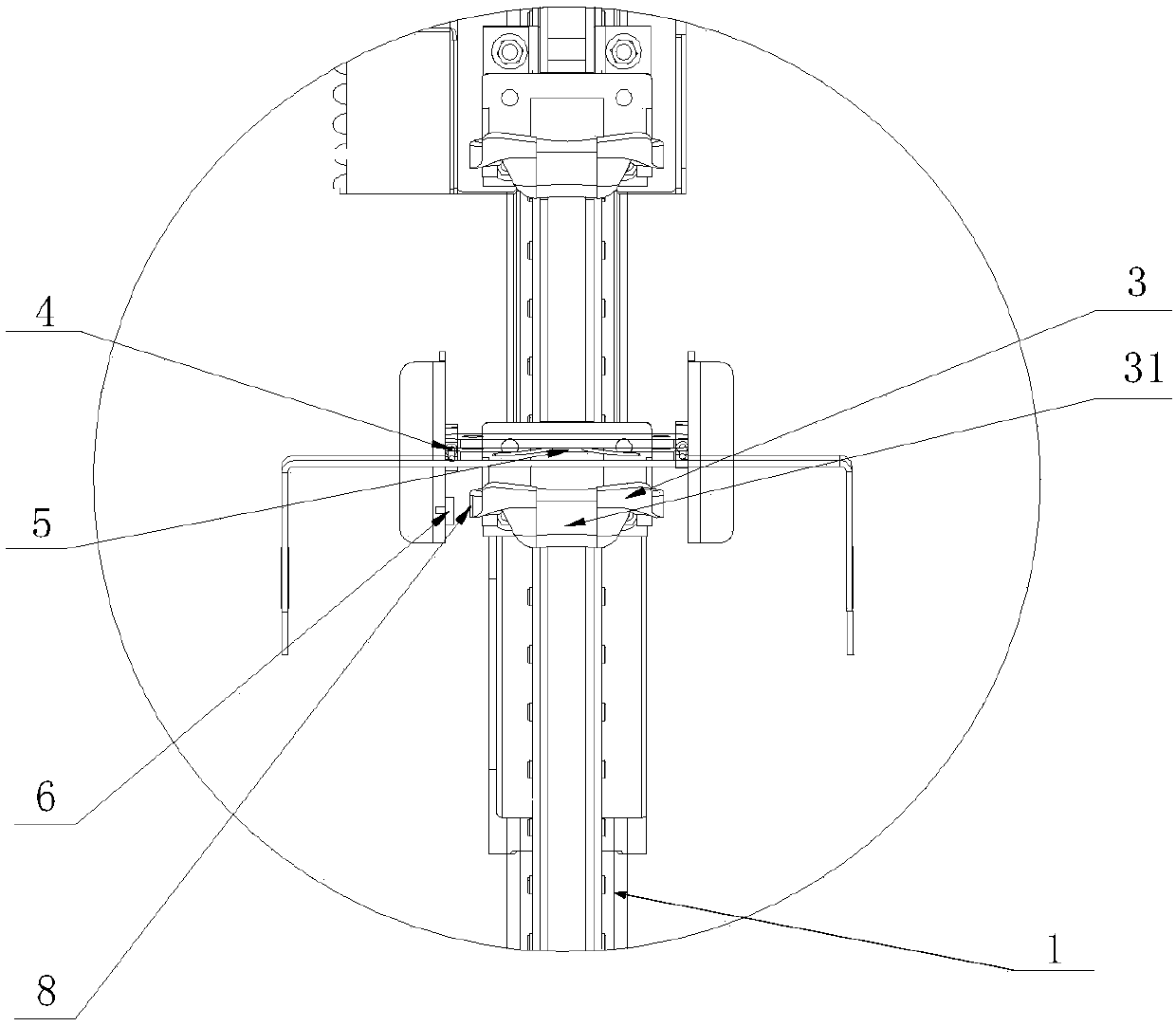

[0044] Embodiment 2, based on the missed sowing detection-replanting system described in embodiment 1, it is applied in the field of potato sowing control, specifically, includes an intelligent controller and a missed sowing detection sensor connected thereto, a Hall sensor, and an encoding speed sensor And seeding direct current motor 7; Missed sowing detection sensor comprises photoelectric sensor and piezoelectric sensor, reference figure 2 and image 3 , the photoelectric sensor 4 is arranged on the chassis 2 on both sides of the spoon chain 1; the upper edge of the seed picking spoon 3 is provided with a gap, the piezoelectric sensor 5 is fixedly arranged on the chassis and corresponds to the gap 31, and the seed picking spoon 3 A magnetic metal sheet 8 is also provided at the central position of the side, and the Hall sensor 6 is fixedly installed on the chassis 2 and corresponds to the magnetic metal sheet 8 on the seed picking spoon at a certain moment, and the positi...

Embodiment 3

[0049] Embodiment 3, present embodiment is based on the control system proposed in embodiment 2, proposes a kind of potato miss-seeding detection-replanting method, comprises the following steps:

[0050] A. System initialization, set planting spacing;

[0051] B. When the encoding speed sensor detects that the bottom wheel starts to run, the intelligent controller controls the drive module to drive the seeding DC motor to run according to the set distance between plants to sow seeds;

[0052] C. Leaked sowing detection: During the sowing process, the Hall sensor, photoelectric sensor and piezoelectric sensor jointly detect to determine whether the current seed picking spoon is short of seeds;

[0053] When the Hall sensor is aligned with the position of the seed picking spoon, the signal acquisition of the photoelectric sensor and the piezoelectric sensor is carried out;

[0054] If there is no signal from the photoelectric sensor, it means that the current seed picking spoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com