Cocoa stick chewing tobacco and preparation method thereof

A technology of tobacco and inner layer, applied in the directions of tobacco, tobacco processing, application, etc., can solve the problems of strong pungent, bitter, astringent, pungent taste, etc., and achieve the effects of reducing pungency, strong antioxidant effect, and aroma coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

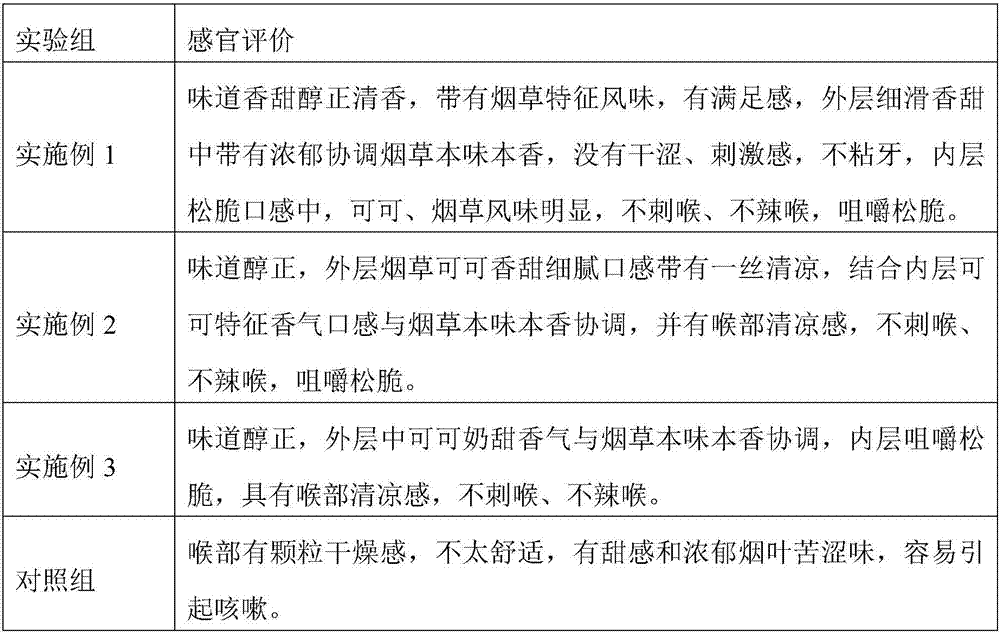

Examples

Embodiment 1

[0029] A kind of cocoa stick chewing tobacco, concrete preparation is as follows:

[0030] 1. Preparation of inner layer of cocoa stick chewing tobacco:

[0031] (1) Tobacco and cocoa mixed fermentation: mix 8 parts of tobacco powder and 15 parts of cocoa powder in the inner layer component by weight and cross a 120 mesh sieve, add 90% water of the inner layer component gross weight, stir evenly, Add 0.1 part of compound enzyme accounting for the total weight of tobacco powder and cocoa powder, incubate and stir ferment at 40°C for 0.6h, decompose and transform the protein and cell wall substances in tobacco and cocoa into free amino acids and reducing sugars, decompose and release more fragrance Substance, obtain tobacco and cocoa composite fermented liquor;

[0032] The compound enzymes are protease and β-glucosidase, both of food grade, with enzyme activities of 200,000u / g and 10,000u / g respectively, and a weight ratio of 8:1.

[0033] (2) According to the weight ratio of...

Embodiment 2

[0043] A chocolate bar chewing tobacco, the specific preparation method is as follows:

[0044] Wherein 1. the preparation of chocolate stick chewing tobacco inner layer is as follows:

[0045] (1) Tobacco and cocoa mixed fermentation: 10 parts by weight of tobacco powder and 13 parts of cocoa powder in the inner layer component are mixed through an 80 mesh sieve, and water with 120% of the total weight of the inner layer component is added, stirred evenly, Add 0.2 parts of compound enzymes accounting for the total weight of tobacco powder and cocoa powder, incubate and stir fermentation at 48°C for 1 hour, decompose and transform the protein and cell wall substances in tobacco and cocoa into free amino acids and reducing sugars, decompose and release more flavor substances , obtaining tobacco and cocoa composite fermentation liquid;

[0046] The compound enzymes are protease and β-glucosidase, both of food grade, with enzyme activities of 100,000u / g and 5,000u / g respectively...

Embodiment 3

[0057] A cocoa stick chewing tobacco, the specific preparation method is as follows:

[0058] Wherein 1. the preparation of cocoa stick chewing tobacco inner layer is as follows:

[0059] (1) Tobacco and cocoa mixed fermentation: 14 parts by weight of tobacco powder and 9 parts of cocoa powder in the inner layer component are mixed through a 60-mesh sieve, and 130 parts of water by the total weight of the inner layer component are added, stirred evenly, Add 0.3 parts of compound enzymes accounting for the total weight of tobacco powder and cocoa powder, incubate and stir ferment at 52°C for 1.5 hours, decompose and transform the protein and cell wall substances in tobacco and cocoa into free amino acids and reducing sugars, decompose and release more flavors Substance, obtain tobacco and cocoa composite fermented liquor;

[0060] The compound enzymes are protease and β-glucosidase, both of food grade, with enzyme activities of 50000u / g and 1000u / g respectively, and a weight r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com