High-efficiency scheduling optimization method

An optimized scheduling and high-efficiency technology, applied in control/regulation systems, comprehensive factory control, instruments, etc., can solve problems such as non-optimal solution results and slow algorithm convergence speed, and achieve the effect of improving population diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in detail below according to the accompanying drawings.

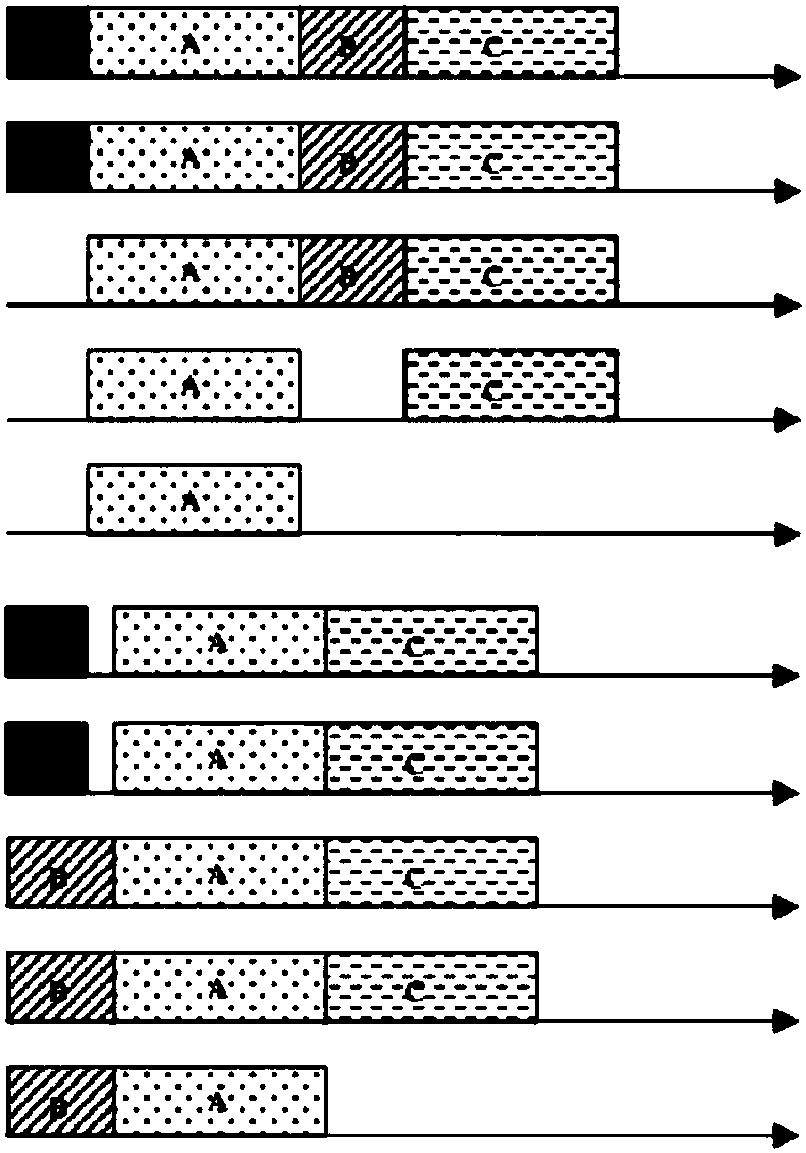

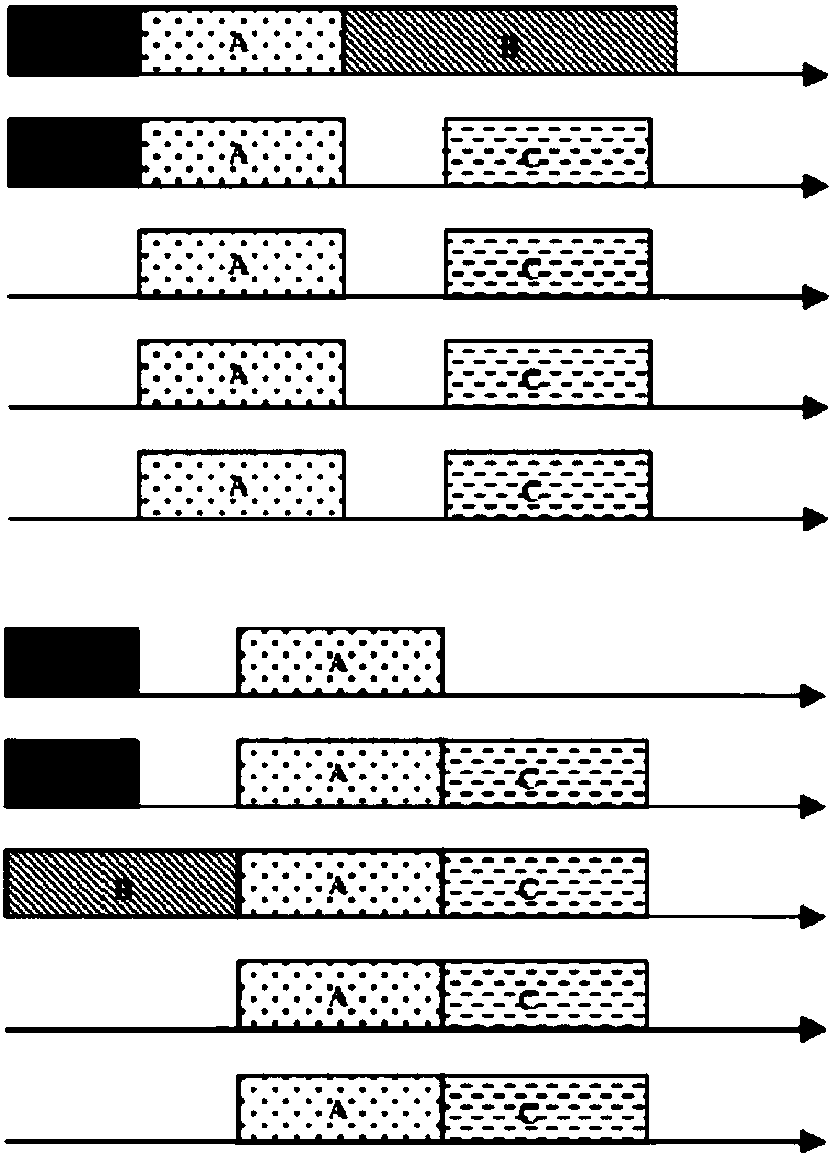

[0057] Assume that there are 9 jobs to be arranged in the 2-stage mixed flow workshop, and each stage has 5 processors. Operation time and processor reference required for each job Figure 9 .

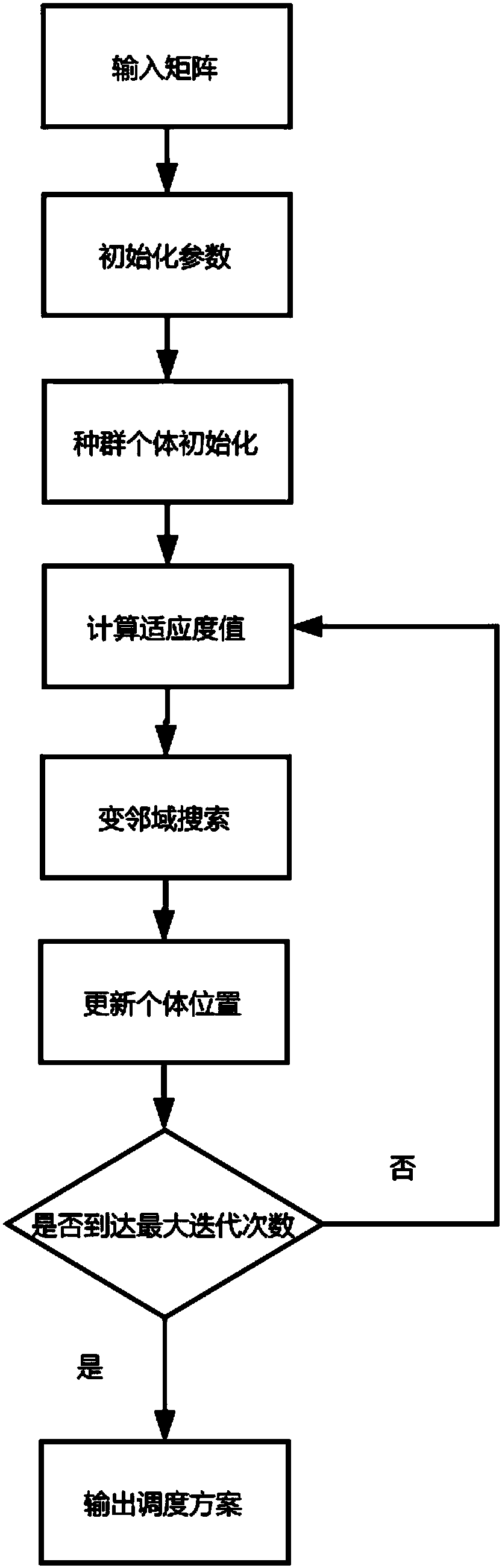

[0058] refer to figure 1 . The method flow includes the following steps:

[0059] 1) The values of matrix size and p are based on Figure 9 enter.

[0060] 2) Parameter setting, the number of individuals in the population N, the maximum number of iterations t max , random parameter α, individual attraction β 0 , medium absorption rate γ; where N=20, t max =500, α=0.5, β 0 =0.2, γ=1.

[0061] 3) Population individual initialization.

[0062] Generate population X=(x 1 ,x 2 ,...,x N ), the sth individual x in the population s =(x s1 ,...,x s9 ), x sj It is a real number between 0 and 9, s∈{1,2,…,N}, j∈{1,2,…,9}. due to individual x s The coordinates of are contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com