Automatic jacketing machine and gasket punching and installation device thereof

A technology for installing devices and gaskets, which is applied in the direction of sustainable manufacturing/processing, climate sustainability, non-aqueous electrolyte batteries, etc., and can solve the problems of low production efficiency, low degree of automation, and fewer processing stations of casing machines, etc. Achieve the effect of simple structure, high degree of automation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

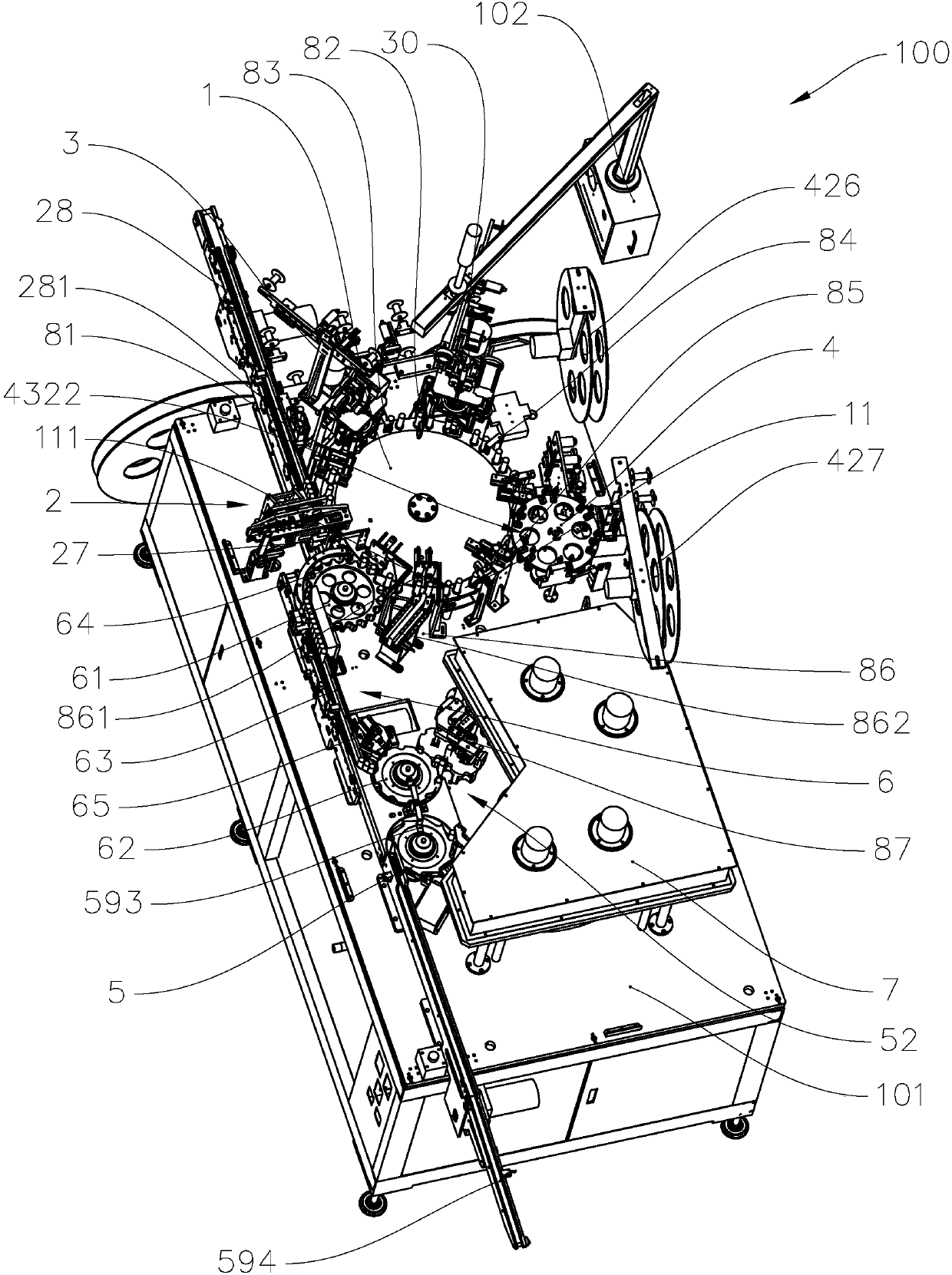

[0038] Example of automatic casing machine:

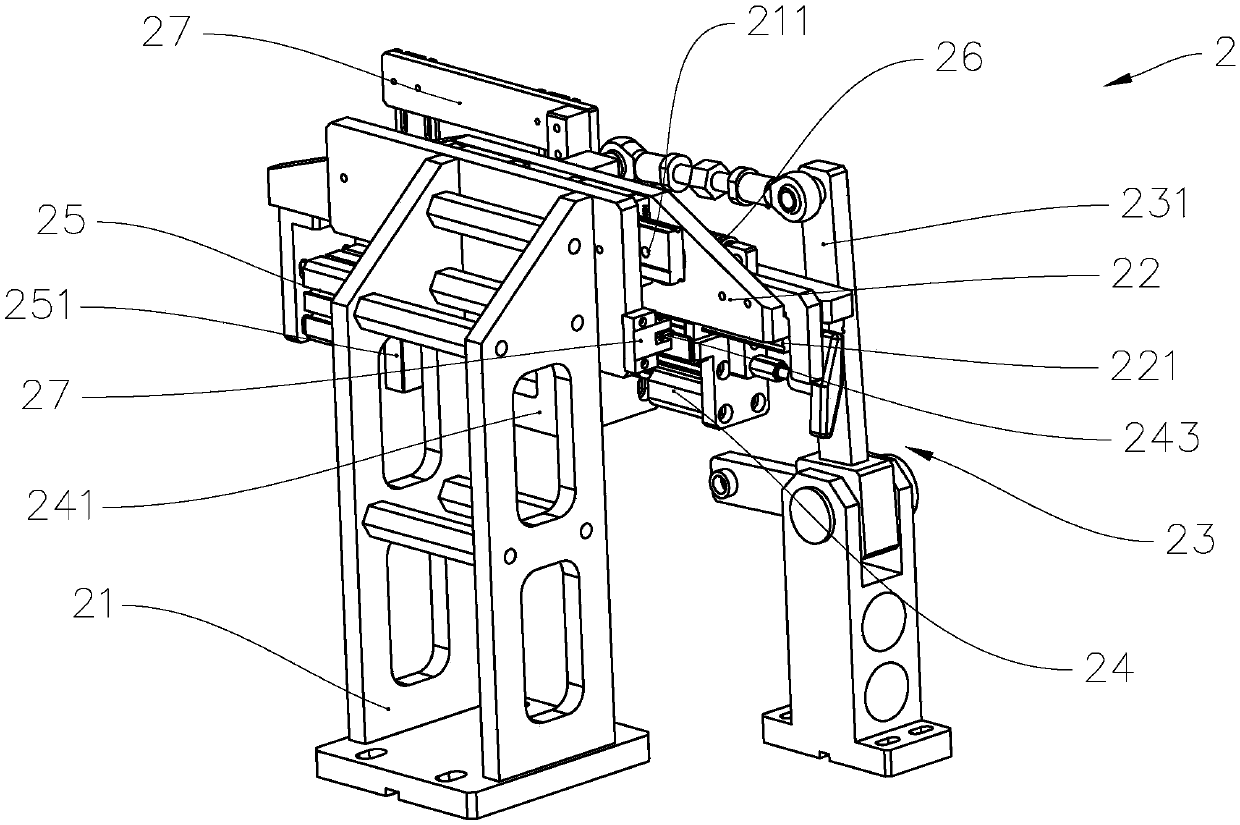

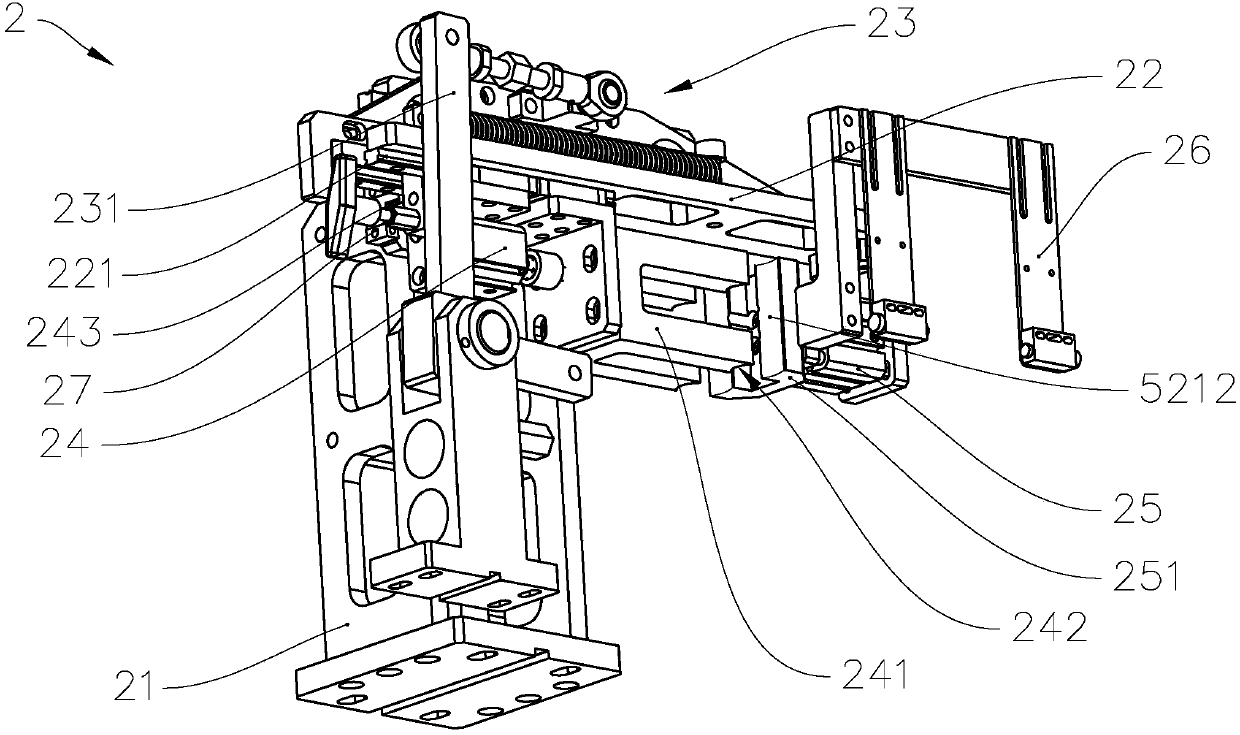

[0039] refer to figure 1 , the automatic casing machine 100 includes a drive system, a workbench 101, a control system 102, a turntable 1, a feeding device 2, a casing device 3, a casing device 30, a gasket stamping installation device 4, a discharge device 5, and a transition turntable Group 6, shrink furnace 7, battery detection device 81, battery detection device 82, rubber hose detection device 83, rubber hose detection device 84, gasket detection device 85 and exclusion device 86. The driving system is installed in the workbench 101, and the driving system is respectively connected with the turntable 1, the feeding device 2, the casing device 3, the casing device 30, the gasket stamping installation device 4, the discharging device 5 and the transition turntable group 6. The control system 102, the control system 102 is electrically connected with the feeding device 2, the sleeve device 3, the sleeve device 30, the gasket sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com