Raw material smashing and mixing-stirring processing mechanism for lithium battery production

A technology for mixing and stirring lithium batteries, which is applied to mixers, mixers with rotary mixing devices, and accessories of mixers, etc., can solve the problems of failure to meet the requirements of crushing accuracy, failure to achieve rapid and uniform mixing, and unfavorable lithium battery production. Improved work efficiency, automation, uniform and fine crushing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

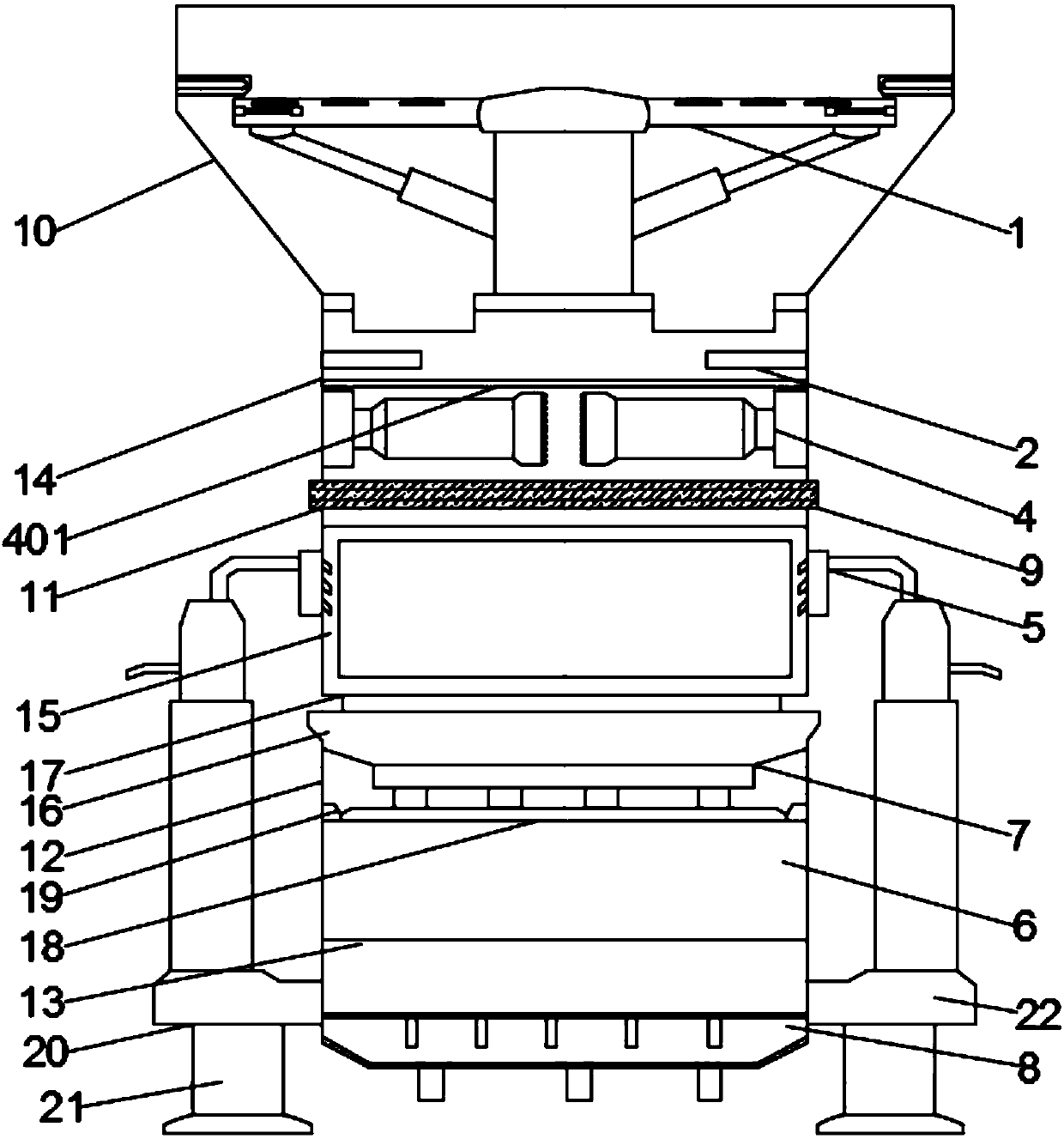

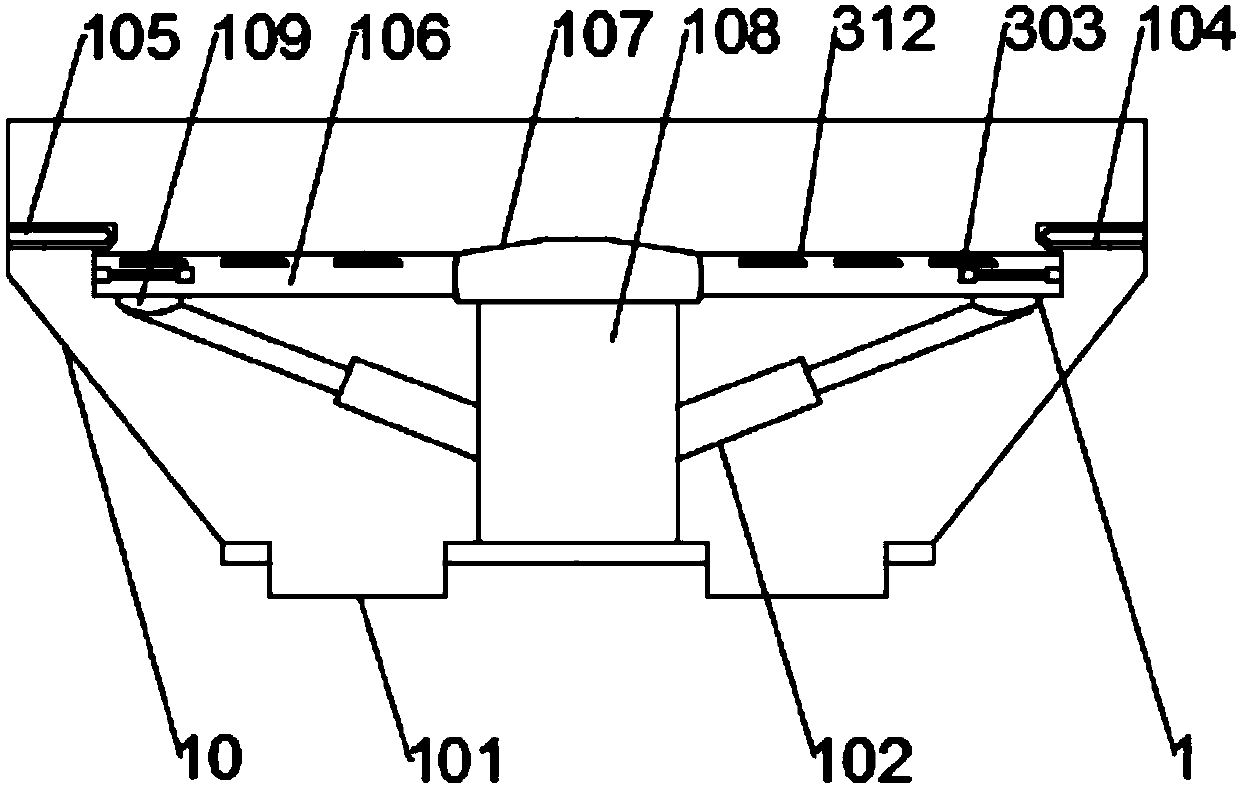

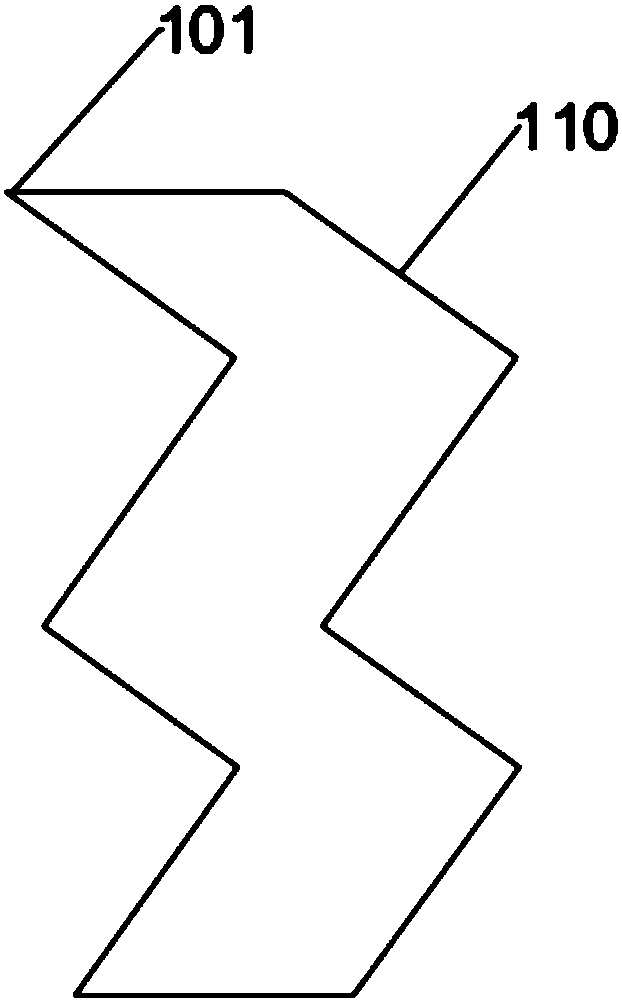

[0047] Such as Figure 1 to Figure 15 As shown, the present invention provides a mixing and stirring treatment mechanism for lithium battery production of pulverized raw materials, including a coarse material feeding cylinder 10, a pulverizing cylinder 11, a mixing cylinder 12 and a discharging cylinder 13, and the coarse material feeding cylinder 10 and An anti-blocking connection device 2 is provided between the crushing cylinders 11, and the crushing cylinder 11 and the mixing cylinder 12 are connected through a connecting bucket 16, and the mixing cylinder 12 and the discharge cylinder 13 are fixedly connected to the coarse material feeding cylinder 10 Including an automatic feeding device 1 installed inside the coarse material feeding cylinder 10 and a weighing device 3 installed above the automatic feeding device 1, the crushing cylinder 11 includes a coarse and fine grinding cylinder connected with the coarse material feeding cylinder 10 14 and the fine and fine pulveri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com