Color master batch drying and impurity removing device robot manufacturing process

A technology of machine manufacturing and color masterbatch, which is applied in the field of machine manufacturing process of color masterbatch drying and impurity removal device, which can solve the problems of poor screening effect, low production efficiency, and low degree of intelligence, so as to speed up production efficiency and improve efficiency , the effect of reducing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

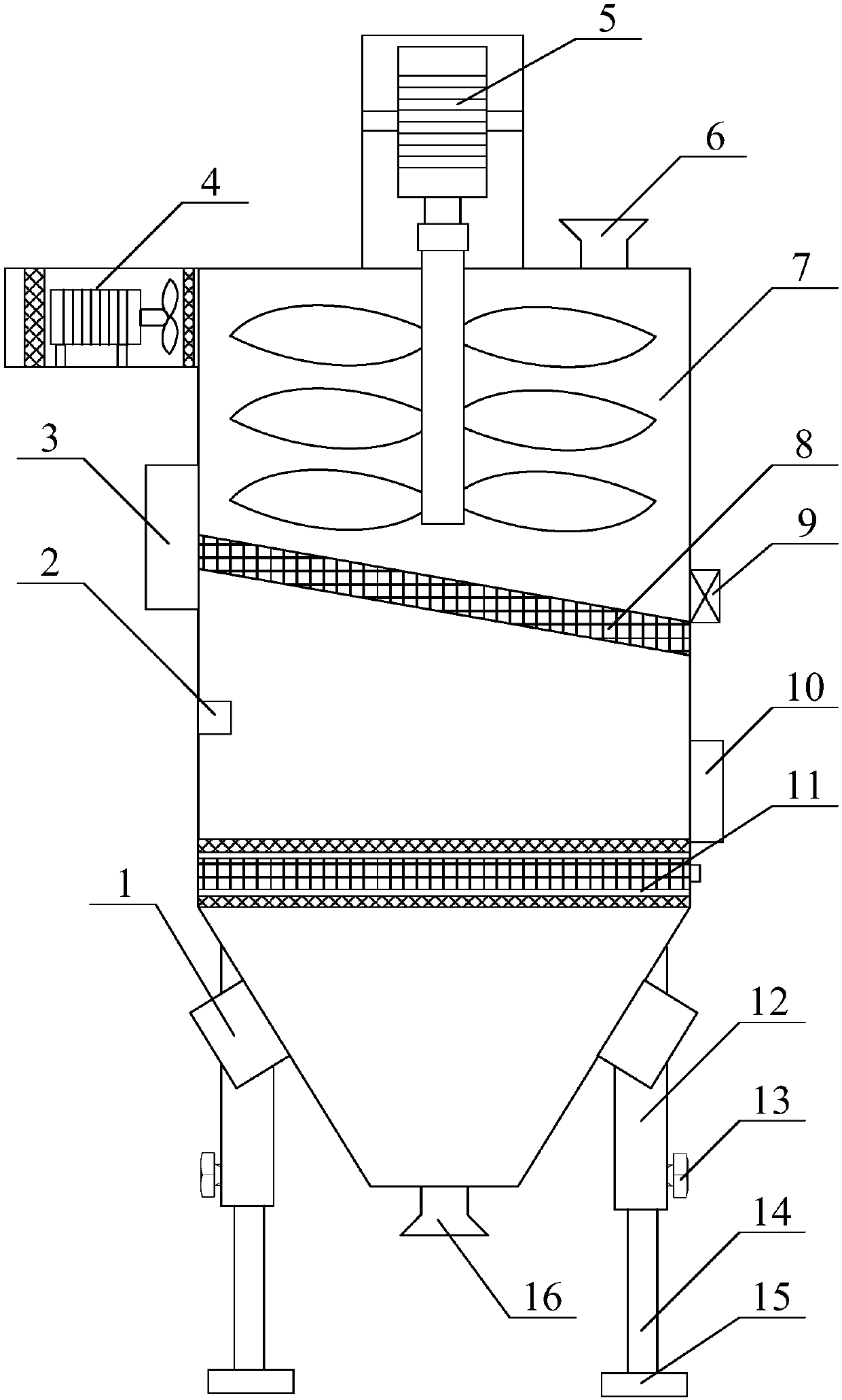

[0032] as attached figure 1 to attach Figure 5 shown

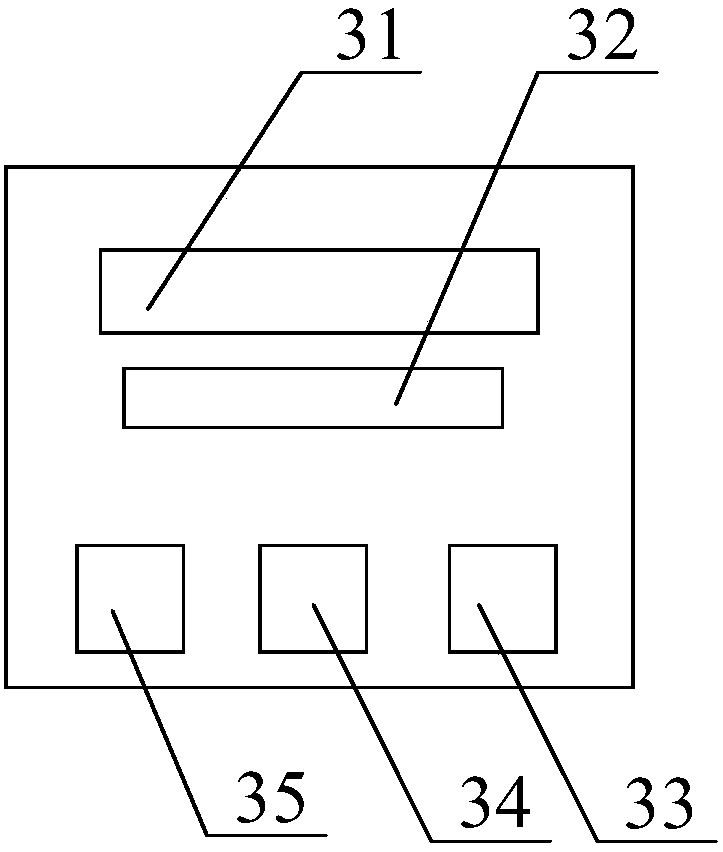

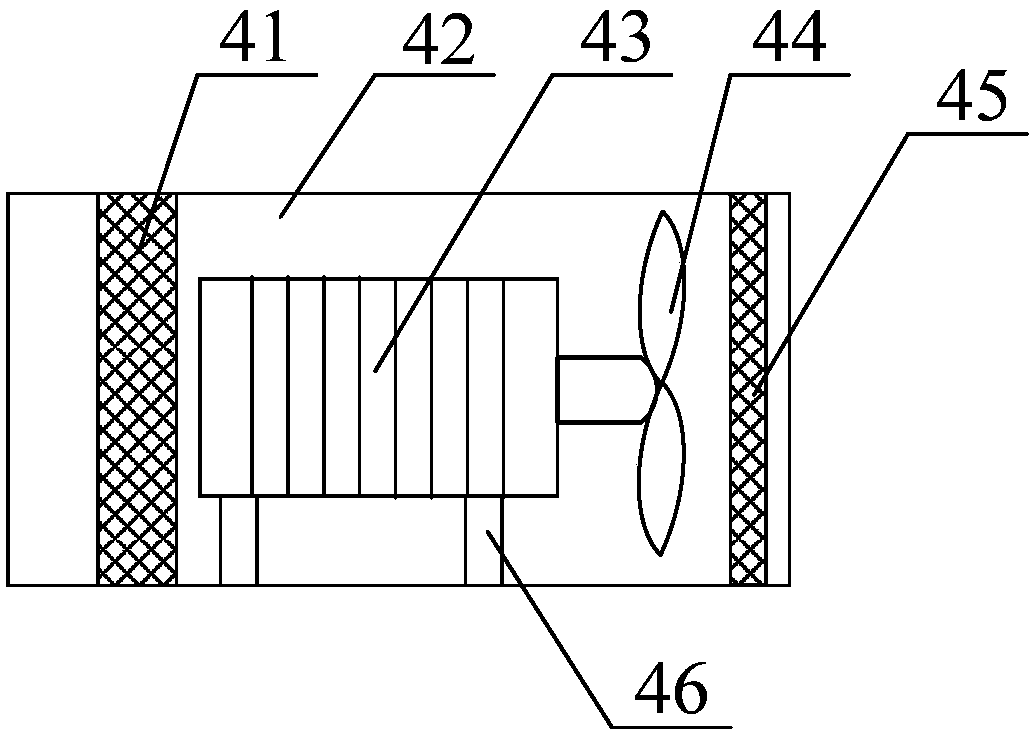

[0033] The invention provides a machine manufacturing process for a color masterbatch drying and impurity removal device, including a dryer 1, a temperature and humidity sensor 2, a control cabinet 3, a dust processing device 4, a stirring device 5, a feeding pipe 6, a drying and dust removal tank 7, and a filter screen 8. Control valve 9, sample intake door 10, fine sieve separation device 11, sleeve 12, locking bolt 13, sleeve rod 14, shock absorbing pad 15 and discharge pipe 16, and the bolts of the dryer 1 are respectively Connected to the left and right sides of the bottom of the dry dust removal tank 7, the temperature and humidity sensor 2 is pasted on the inner left middle position of the dry dust removal tank 7, and the control cabinet 3 bolts are connected to the upper left part of the dry dust removal tank 7, so The right side of the dust processing device 4 is welded to the upper left part of the dry dust re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com